Maintaining a high-performance garden tool requires understanding the key components that make it function. Whether you are repairing a malfunction or upgrading specific parts, knowing where each element fits into the whole system is crucial for a smooth operation.

In this guide, we will explore the essential elements of your device, helping you to clearly identify, replace, and maintain them for optimal results. With clear visual aids and detailed descriptions, you’ll gain a deeper insight into how each part contributes to your tool’s effectiveness and longevity.

Proper upkeep ensures not only the longevity of your equipment but also enhances its efficiency. Recognizing common issues early on can save time and money by addressing problems before they worsen.

Understanding Lawn Equipment Components

Every garden tool is made up of several critical components that work together to ensure efficient performance. Understanding the role of each element can greatly enhance the repair and maintenance process, making it easier to identify problems and implement solutions.

Some of the most important sections of a device include the motor, battery, and cutting system. These parts interact with one another to provide power, maneuverability, and precise operation. Familiarity with these elements allows for smoother handling during routine maintenance or troubleshooting.

By gaining insight into the layout and function of these parts, users can also gain better control over their equipment, ensuring consistent results and preventing unnecessary wear and tear. Knowing where each part fits into the overall structure is essential for achieving long-term reliability.

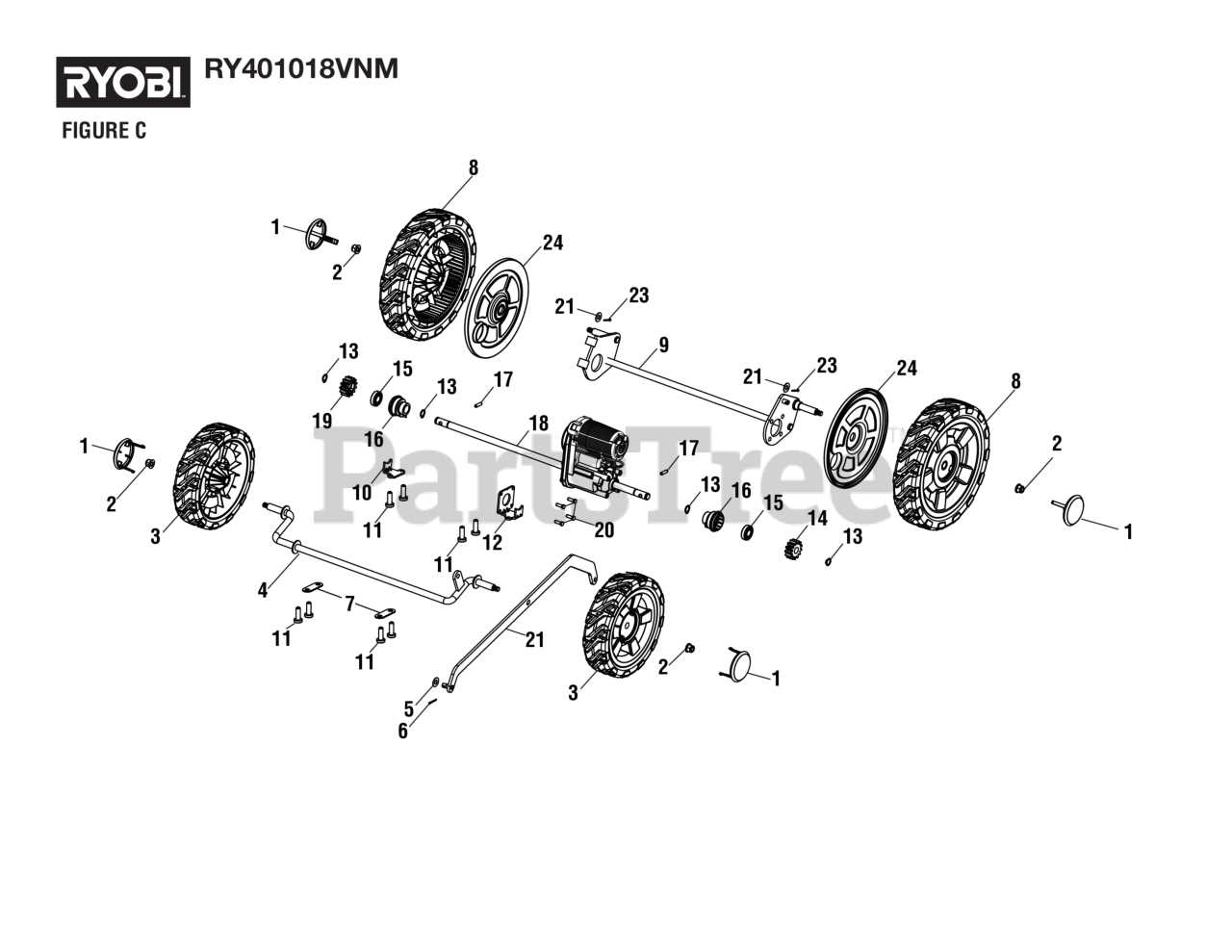

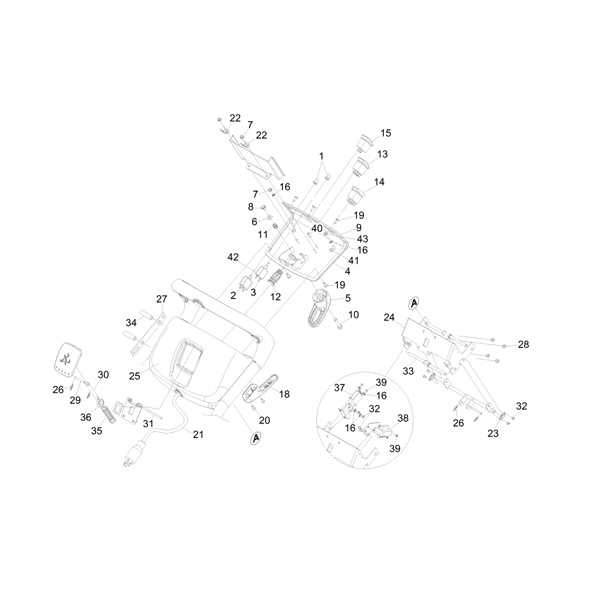

How to Identify Components in the Diagram

Recognizing and understanding the various components of your equipment is essential for efficient maintenance. A clear, well-labeled illustration can help pinpoint each part, making repairs and replacements simpler and more accurate.

Start by focusing on the key elements, such as the motor assembly, the energy source, and the cutting mechanism. These are typically highlighted in the visual representation, allowing for easy identification. Pay close attention to the numbers or labels associated with each part, as these will guide you in matching the components with their real-world counterparts.

It’s also important to familiarize yourself with the overall layout of the tool. Understanding the relative position of each component in the diagram will provide a clearer picture of how they function together. This knowledge is invaluable when troubleshooting or replacing specific parts in the future.

Common Issues and Part Replacements

Even the most reliable equipment can experience wear and tear over time. Identifying common problems early can help prevent further damage and reduce the need for costly repairs. Knowing which components are most likely to need replacing is essential for efficient upkeep.

Battery and Power Supply Problems

One of the most frequent issues users face is a loss of power. Over time, the energy source may degrade, leading to reduced performance. Replacing the battery or the power unit can restore functionality, allowing for consistent operation. Checking connections and ensuring proper charging can also help avoid unnecessary replacements.

Blade and Cutting System Issues

Another common issue is dull or damaged blades. When the cutting system no longer provides a clean and precise cut, it’s time for an inspection. Replacing worn blades or adjusting the cutting mechanism can help improve efficiency and performance. Regular maintenance of these elements is key to ensuring the tool continues to function effectively.