When it comes to maintaining outdoor machinery, knowing the essential components and how they fit together is crucial. Understanding the internal structure and mechanics of the equipment can help in troubleshooting, repairs, and ensuring smooth operation. Identifying the different elements and their specific functions ensures that you can keep your gear in optimal working condition for longer periods of time.

Every machine comes with a detailed visual guide that maps out its different elements, giving users a clearer picture of how each part works in relation to the others. Familiarizing yourself with this guide allows for more efficient repairs, replacements, and adjustments. With the right knowledge, you can address issues quickly without unnecessary downtime or excessive costs.

In this article, we will explore how to properly interpret such guides, focusing on the main components and how to identify common problems. Knowing what each piece does and where it fits into the larger system is key to effective maintenance and troubleshooting.

Understanding the Swisher 44 Mower Parts

When working with large-scale lawn maintenance equipment, recognizing the various components that contribute to its functionality is essential. These machines are designed with precision, combining multiple elements that work together to provide efficiency and reliability. Familiarity with each part helps ensure optimal performance and can assist in the troubleshooting and maintenance process.

Each segment of the machine plays a specific role in achieving a smooth and effective cutting experience. From the engine to the cutting mechanism, understanding the function of every section is key to extending the lifespan of the equipment. Key components often include:

- Engines or power sources

- Transmission systems

- Cutting blades and their holders

- Control mechanisms for maneuvering

- Support frames and attachments

By gaining insight into these essential sections, users can better diagnose issues, perform maintenance tasks, and ensure a trouble-free experience when operating this type of equipment.

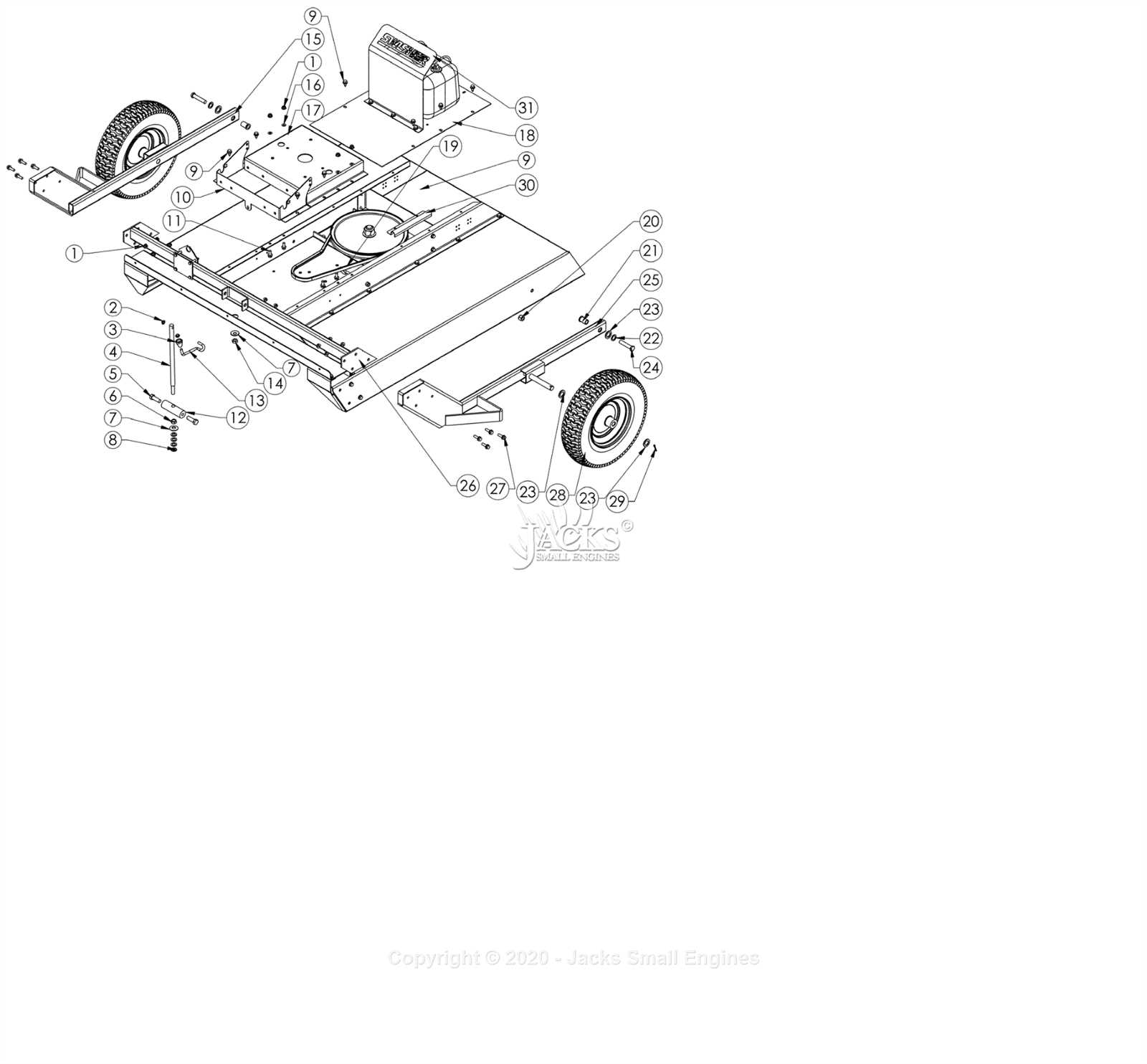

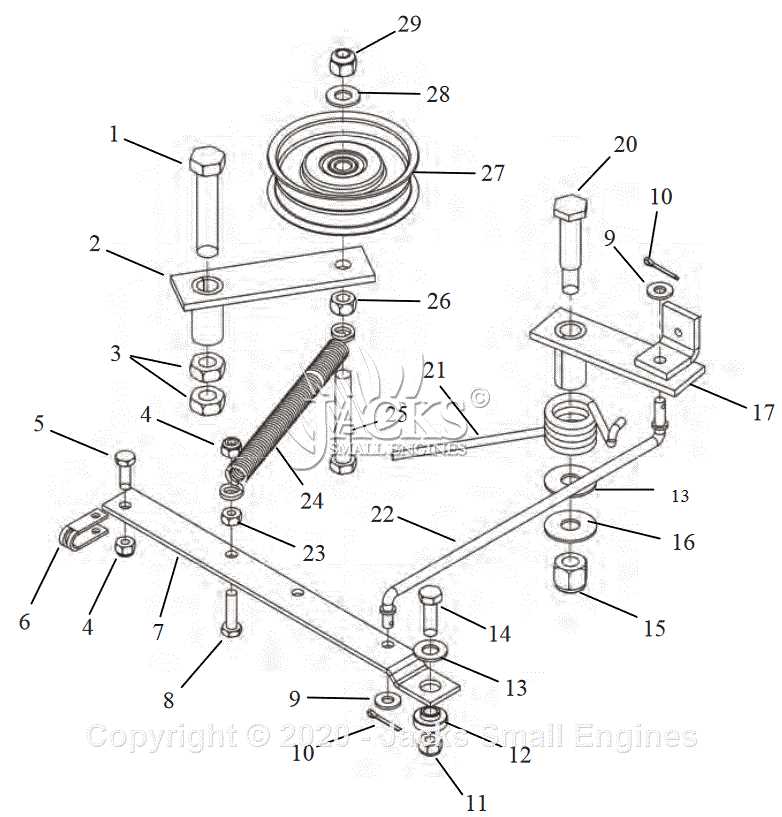

Identifying Key Components in the Diagram

Understanding the essential elements of a machine layout is crucial for effective maintenance and repairs. By analyzing the visual representation, you can pinpoint critical components that ensure proper functionality. This section will guide you through the primary sections and mechanisms typically illustrated, enabling you to recognize each part’s role and significance.

Structural Elements

The framework forms the base of any equipment and holds various components in place. It is important to identify the supports, brackets, and connections that secure the rest of the mechanisms. These structural elements are essential for maintaining the integrity and stability of the entire system.

Functional Components

Moving parts, such as the blades and drive system, are responsible for the machine’s performance. Recognizing their position and connection helps in understanding how the equipment operates. The functional components, including belts, pulleys, and linkages, play a vital role in transferring motion and power across different parts.

How to Replace Mower Components

Replacing key components of your machine is an essential skill to ensure its continued operation. By following the correct steps and using appropriate tools, you can efficiently perform replacements. This guide will walk you through the process of identifying when parts need to be swapped out and the proper method for replacing them.

Steps for Component Replacement

Before replacing any components, ensure the machine is turned off and disconnected from any power source. Begin by removing the damaged or worn-out parts, taking care to follow the instructions for detaching them without causing damage to other mechanisms. Once the old components are removed, match the new parts with the specifications provided in the manual.

Tools You Will Need

Having the right tools makes the process smoother and ensures a proper fit for the new parts. Below is a table listing common tools required for the replacement procedure.

| Tool | Purpose |

|---|---|

| Wrenches | For loosening and tightening bolts |

| Socket Set | For removing nuts and bolts |

| Screwdrivers | For detaching screws |

| Lubricant | To prevent rust and ease movement |

Step-by-Step Guide for Maintenance

Regular upkeep is essential to keep your equipment running smoothly and avoid costly repairs. A step-by-step approach allows you to maintain the machine efficiently and identify potential issues before they become problems. This guide will provide you with a clear outline for maintaining your equipment to ensure long-lasting performance.

Initial Preparations

Before starting any maintenance work, ensure that the equipment is powered off and that all safety precautions are in place. Clear the area of any obstacles and gather all necessary tools. It is important to check the owner’s manual for specific recommendations on the required frequency of maintenance tasks.

Routine Maintenance Tasks

Perform regular checks to keep the equipment in optimal condition. Start by inspecting the frame for any signs of wear or damage. Lubricate moving parts to reduce friction, and check the tension on belts or cables. Clean any debris from the components and replace filters or fluids as needed.

Common Issues with Lawn Equipment

Over time, all machines experience certain issues that can hinder their performance. Recognizing these common problems early can save you time and money. This section highlights frequent complications with lawn care devices and how to address them effectively.

Power and Starting Problems

One of the most common challenges is difficulty in starting or a complete lack of power. Dirty filters, clogged fuel lines, or a faulty spark plug often contribute to this issue. Regular cleaning and timely replacement of these components can restore optimal functionality. Ensure that the fuel is fresh and not contaminated, as old fuel can cause starting failures.

Uneven Cutting

If the device leaves uneven patches of grass, the issue could lie with blades that are dull or misaligned. Check for any visible damage to the blades and replace them if necessary. It is also important to verify that the deck is level, as an unbalanced setup can lead to poor cutting results.