Maintaining outdoor machinery can often seem like a complex task, especially when it comes to understanding the intricate components involved. However, with a clear understanding of how each part works together, the process becomes much easier. Knowing the basic structure of your equipment is crucial for troubleshooting, repairs, and effective operation.

Identifying the individual elements of a lawn care machine and recognizing their specific roles allows for better upkeep and a longer lifespan. Understanding the different sections of the machine provides clarity on how the entire system functions, ensuring efficient performance throughout its use.

By reviewing these key components, users can gain confidence in maintaining their machinery, whether it involves simple tasks like replacing a worn part or more involved repairs. A solid understanding of how everything fits together can prevent unnecessary delays and costly professional service.

Understanding the Lawn Equipment Components

Every outdoor machine is made up of several essential elements, each playing a critical role in its overall function. By familiarizing yourself with these components, you gain the knowledge needed to effectively manage maintenance and repairs. This understanding makes it easier to diagnose problems and ensure the smooth operation of the equipment.

Key sections such as the power source, cutting mechanisms, and control systems all work together to deliver optimal performance. Each component must function properly for the entire system to operate efficiently. Regular checks and understanding the role of each part help to prevent malfunctions and extend the life of the machine.

Knowing how the various sections are connected and interact can guide you through the repair process, whether you are replacing a faulty element or simply performing routine checks. A clear grasp of the equipment’s structure enables better decision-making when addressing issues or upgrading individual components.

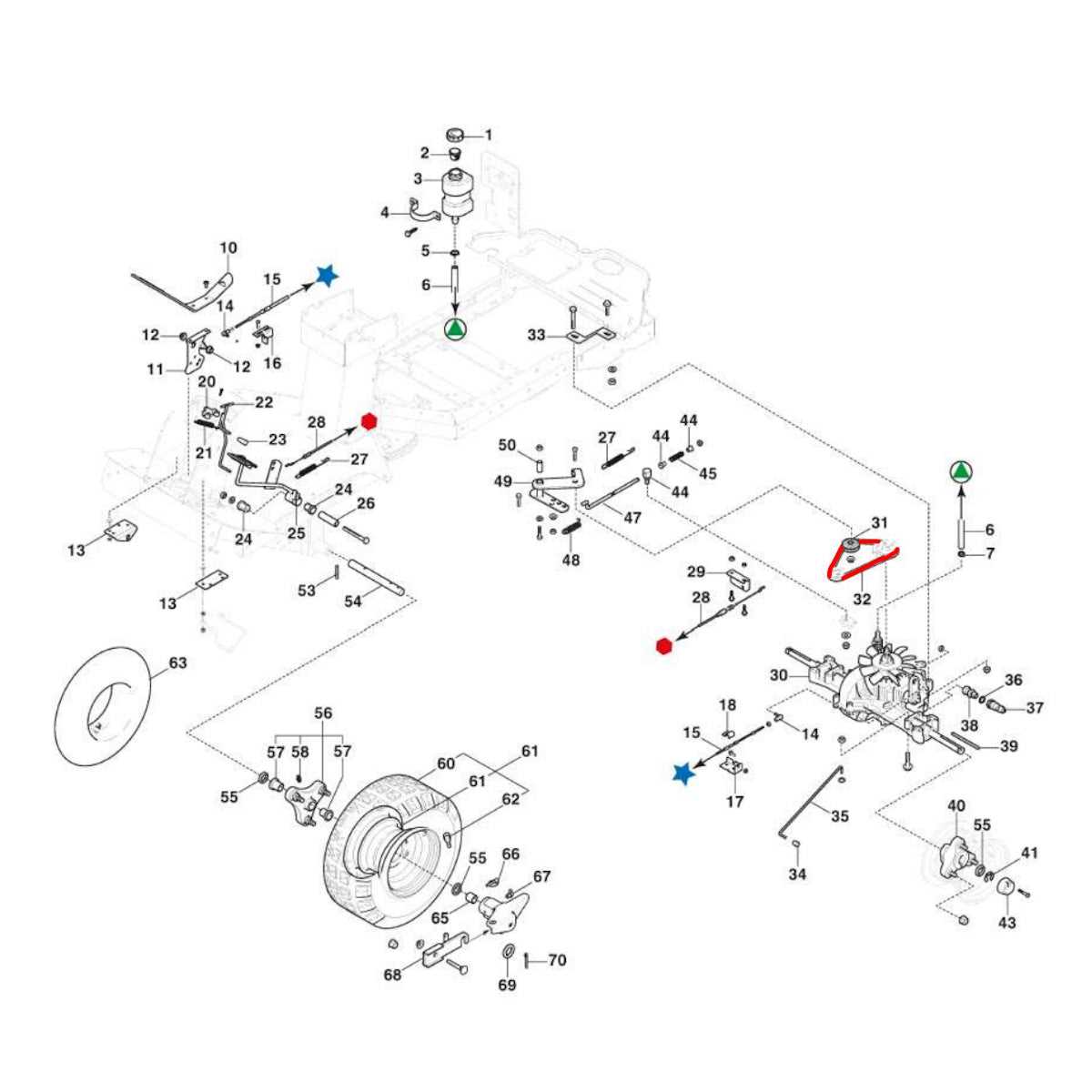

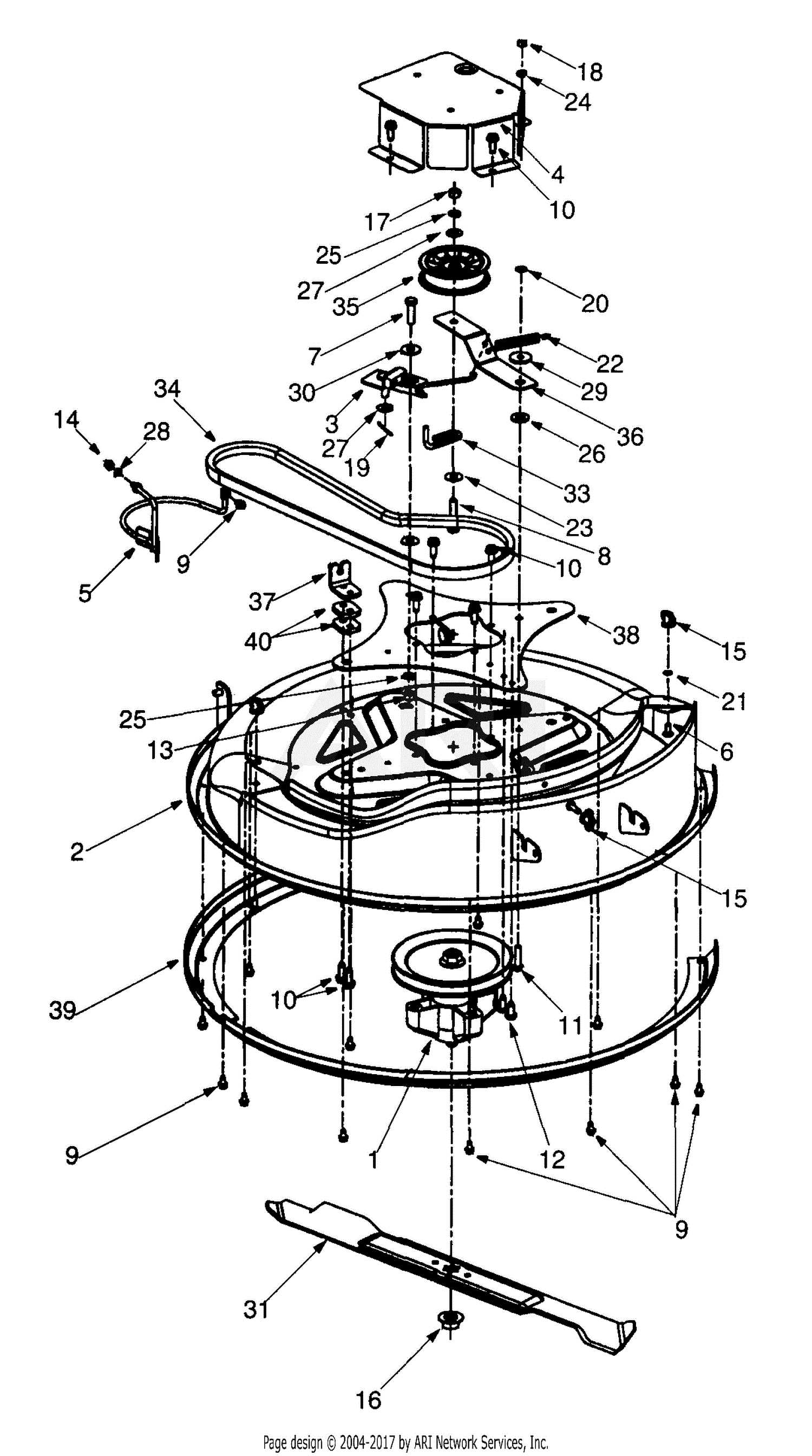

How to Read a Lawn Equipment Schematic

Understanding how to interpret a schematic of your outdoor equipment is crucial for proper maintenance and repair. These diagrams provide a visual guide to the various elements of the machine, helping you identify each part’s location and function. By learning to read these schematics, you can quickly spot issues and know where to focus your attention.

Typically, these schematics use a combination of symbols, labels, and lines to represent components and their connections. Each part is numbered or named, providing clear identification. Additionally, arrows or lines often show how different parts are linked or interact with each other, offering a comprehensive view of the entire system.

To effectively use these visuals, start by familiarizing yourself with the legend or key that accompanies the diagram. This will help you understand the symbols used. Once you recognize the different components, you can trace their relationships and functions, making it easier to diagnose problems or perform repairs with confidence.

Common Issues and Components Replacement Tips

Every outdoor machine faces certain common issues over time, and understanding how to address them is essential for maintaining its performance. Regular inspection helps identify when certain parts need to be replaced or repaired, ensuring that the equipment runs smoothly. Recognizing the signs of wear can prevent further damage and save on costly repairs.

One frequent issue is the dulling of cutting elements, which can lead to uneven results and more strain on the engine. Replacing these components when they show signs of wear ensures cleaner cuts and more efficient operation. Another common concern is the engine failing to start, which could be due to issues with the fuel system or ignition. In these cases, checking the fuel lines and spark plugs is often a good first step.

When replacing damaged or worn parts, always ensure you are using high-quality replacements that are compatible with your equipment. It’s also important to follow the manufacturer’s recommendations for replacement intervals and maintenance schedules. By staying proactive and replacing components at the right time, you can extend the life of your equipment and maintain its peak performance.