When maintaining your pool cleaning system, having a clear understanding of its components is essential for effective upkeep. Each element plays a crucial role in ensuring smooth operation and optimal performance. Identifying and understanding these pieces can help you identify issues early and keep your system running like new.

Proper knowledge of each part allows you to troubleshoot any malfunctions more efficiently. Whether you’re dealing with a malfunctioning component or just performing routine maintenance, knowing how everything fits together is invaluable. By familiarizing yourself with these pieces, you ensure that your system remains reliable throughout its lifespan.

From the motors to the hoses, every section has a specific function that contributes to the overall efficiency of the machine. This guide will provide you with the necessary details to understand how each part contributes to performance and how to care for them to avoid wear and tear.

Understanding the Pool Cleaner Components

A pool cleaning system is composed of several interconnected elements that work together to ensure efficient operation. Each component is designed to perform a specific function, and understanding how they interact can significantly improve maintenance efforts. With a clear understanding of these components, troubleshooting becomes easier, and repairs can be performed with greater precision.

Key Components of the Cleaning System

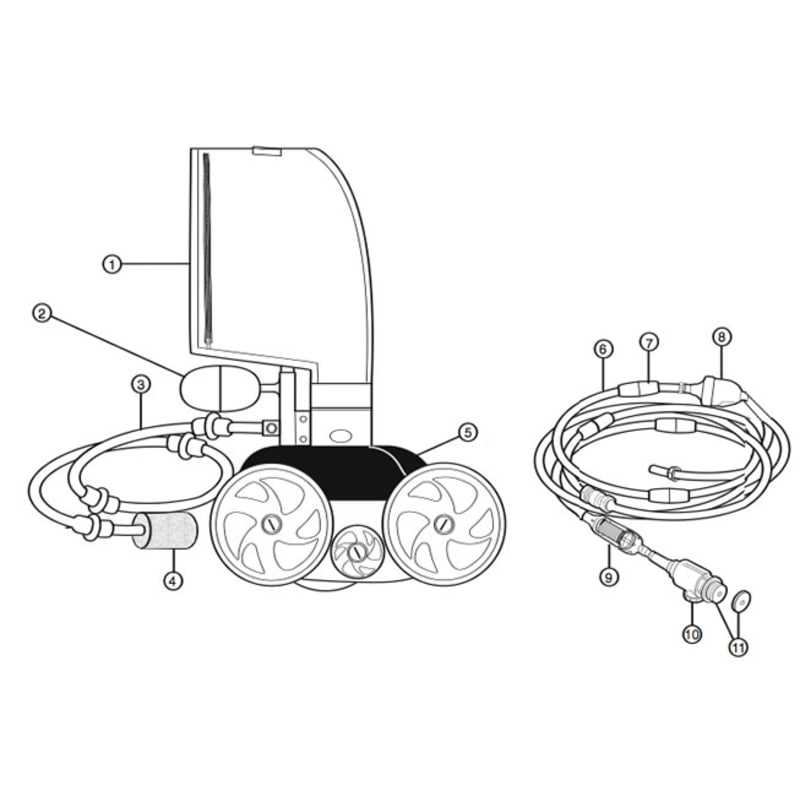

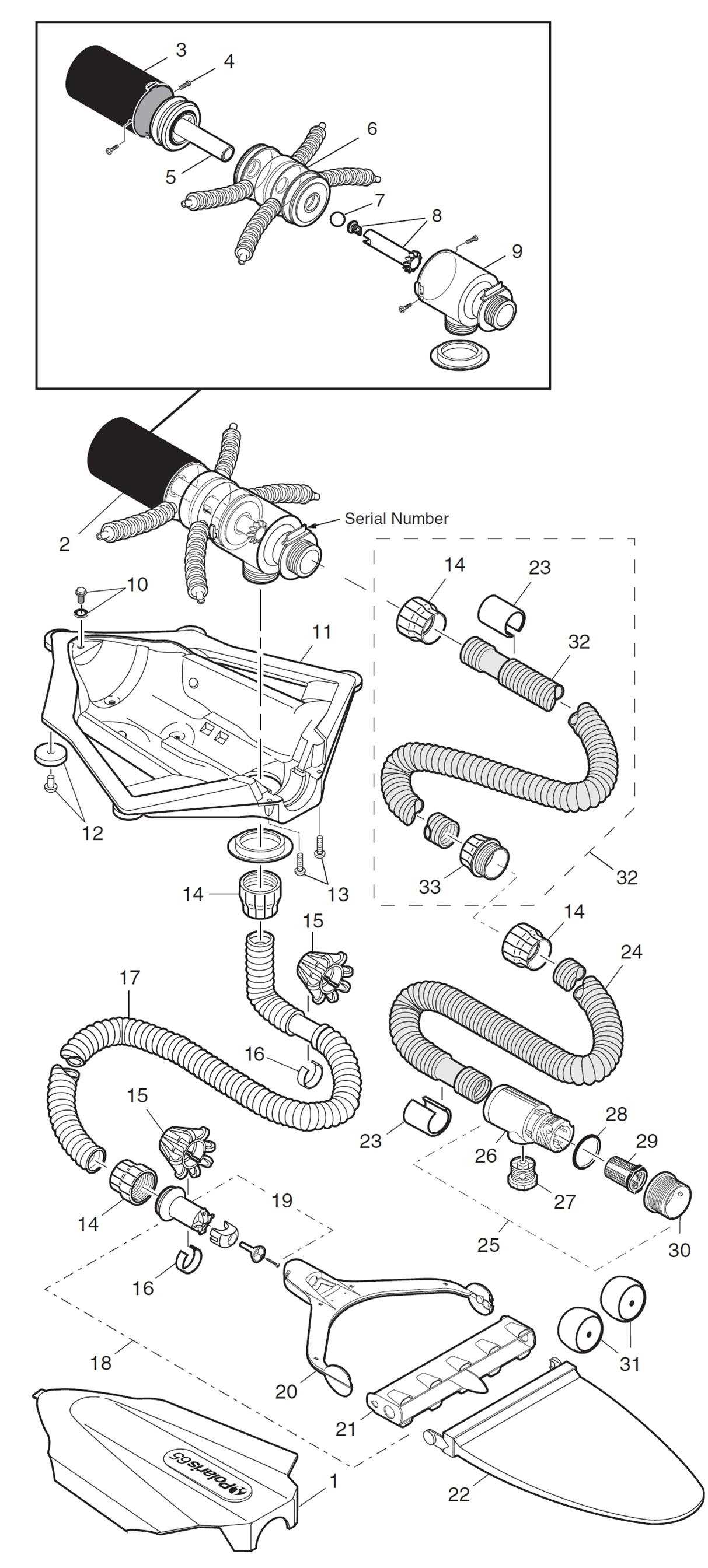

The core of the system includes motors, drive systems, and suction components, all of which ensure the cleaner moves effectively through the pool. The motors power the entire unit, driving the movement and suction. The drive system, which often involves gears or wheels, ensures that the cleaner navigates the pool efficiently, while the suction components collect debris and move it toward the filtration system.

Maintenance and Care for Each Part

Routine inspection and cleaning of each element are essential for extending the life of the pool cleaner. Keeping the motor and drive components free of blockages and ensuring the suction parts remain clear of debris will help maintain optimal performance. Regular maintenance not only ensures longevity but also prevents major breakdowns that could require costly repairs.

How to Read a Pool Cleaner Parts Schematic

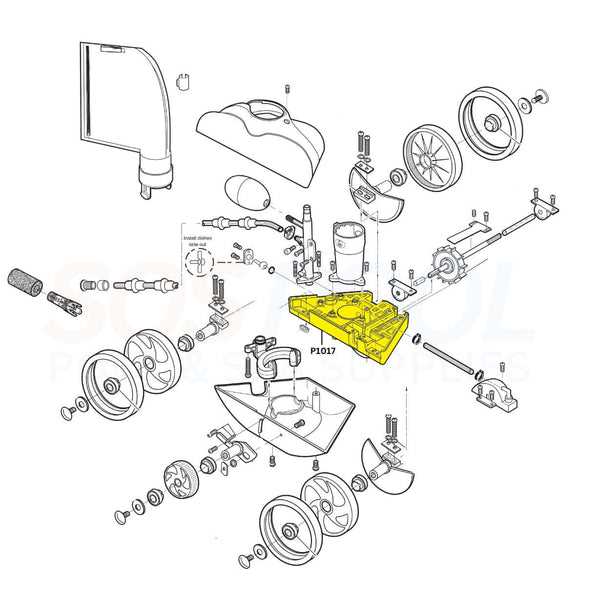

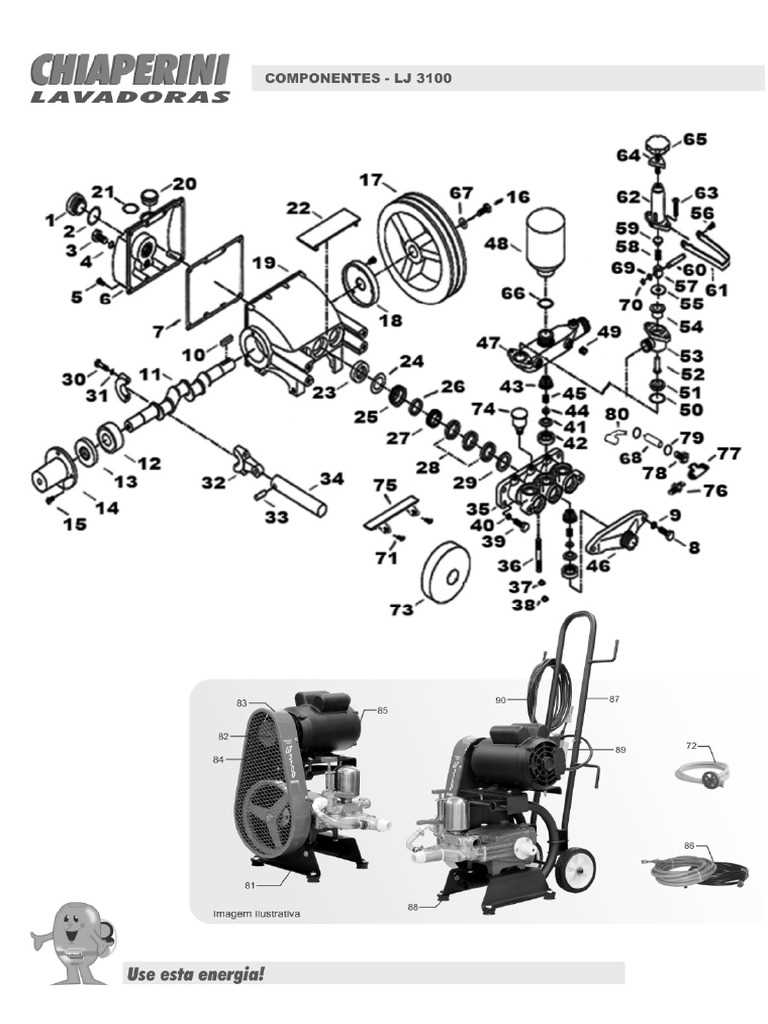

Understanding a schematic for your pool cleaning system is key to identifying each component and its role within the unit. A well-designed schematic provides a clear visual representation of all parts, how they connect, and their specific function. Learning how to interpret this information can simplify repairs and replacements, making maintenance tasks more efficient.

Identifying Key Symbols and Labels

Each component in the schematic is represented by a specific symbol or label that corresponds to a real-world part. Understanding these symbols is the first step in reading the diagram. Typically, parts will be labeled with numbers or letters, which can then be cross-referenced with a parts list for more detailed information on their specifications and replacement options.

Connecting Components and Functions

Once you’re familiar with the symbols and labels, the next step is to understand how each component is connected. The lines in the schematic often represent the flow of energy, fluid, or movement between parts. Recognizing these connections helps you understand the overall operation of the system, making it easier to spot potential issues or areas that need maintenance.

Common Issues with Pool Cleaner Components

Like any mechanical system, a pool cleaning unit is prone to occasional issues, particularly with its moving and suction parts. Understanding the common problems that can arise is crucial for effective troubleshooting and timely maintenance. Recognizing these issues early can save time and prevent further damage to the system.

Clogging and Obstruction Problems

One of the most frequent issues involves blockages in the suction components. Leaves, debris, or even small objects can obstruct the hoses or intake valves, reducing the efficiency of the cleaner. Regularly inspecting and clearing these pathways is essential to ensure smooth operation. Clogs in the hose or filters can also lead to strain on the motor, resulting in further damage if not addressed quickly.

Drive and Movement Malfunctions

Another common issue is related to the drive system, where the cleaner may fail to move or navigate properly. This can be caused by worn-out wheels, broken gears, or a malfunctioning motor. Without proper movement, the cleaner cannot cover the entire pool area, leading to incomplete cleaning. Routine checks and lubrication of moving parts can help avoid these problems and ensure optimal functionality.