When working with a diesel engine, especially for maintenance or repair, understanding its intricate components is essential. A clear breakdown of these parts helps ensure smooth operation and longevity. Knowing how each component interacts with others allows for more effective diagnostics and repairs, minimizing the risk of costly mistakes.

Engine schematics offer a visual representation of how these elements fit together. By analyzing these detailed drawings, mechanics and enthusiasts alike can gain a deeper understanding of the system’s overall structure. This is crucial for both routine maintenance and addressing specific issues that arise over time.

In this guide, we’ll explore the essential components of a typical diesel engine. We’ll discuss how to interpret a schematic and highlight key sections that should be checked regularly for optimal performance. With a thorough understanding of these systems, you’ll be better equipped to handle your engine’s needs and maintain its peak efficiency.

Understanding the Diesel Engine

A diesel engine is a complex system that relies on a variety of interconnected components to function efficiently. Each part plays a specific role in ensuring the engine performs at its best, from generating power to managing exhaust gases. Understanding how these elements work together is key to maintaining optimal engine health and preventing premature failures.

The engine relies on both mechanical and electrical systems, each working in harmony. The key to understanding its function lies in examining how fuel, air, and exhaust gases flow through the engine. With a clear picture of the engine’s internal workings, you can address issues more effectively and ensure that your machine operates smoothly for years to come.

Maintenance and troubleshooting become significantly easier when you know the layout and roles of each part. By familiarizing yourself with how each system contributes to the overall function, you can anticipate potential problems before they occur and make informed decisions during repairs.

Key Components of the Diesel Engine

Understanding the main elements of a diesel engine is crucial for anyone looking to perform repairs or regular maintenance. The engine’s efficiency relies heavily on the performance of these individual components, each of which serves a unique purpose in the overall system. Familiarizing yourself with their functions allows for better diagnostics and troubleshooting.

The following are some of the essential components that make up the engine system:

- Fuel Injectors: Responsible for delivering precise amounts of fuel into the combustion chamber, these components ensure optimal engine performance.

- Turbocharger: This device forces additional air into the combustion chamber, allowing the engine to burn fuel more efficiently and produce more power.

- Intake and Exhaust Valves: These valves control the flow of air and exhaust gases into and out of the engine, helping regulate combustion and engine emissions.

- Crankshaft: The crankshaft converts the linear energy produced by the pistons into rotational energy that powers the vehicle.

- Glow Plugs: These electrical devices help heat the combustion chamber for easier starts, especially in cold weather conditions.

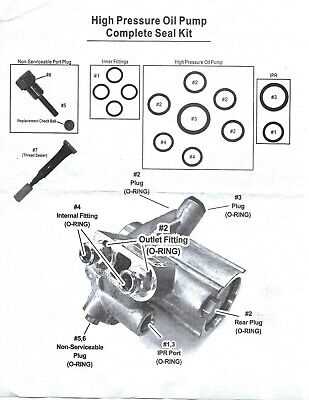

- Oil Pump: The oil pump circulates oil throughout the engine to lubricate moving parts and maintain optimal performance.

Each of these elements works in tandem to ensure that the engine operates at maximum efficiency. Regular inspection and maintenance of these components can help avoid serious issues and extend the lifespan of the engine.

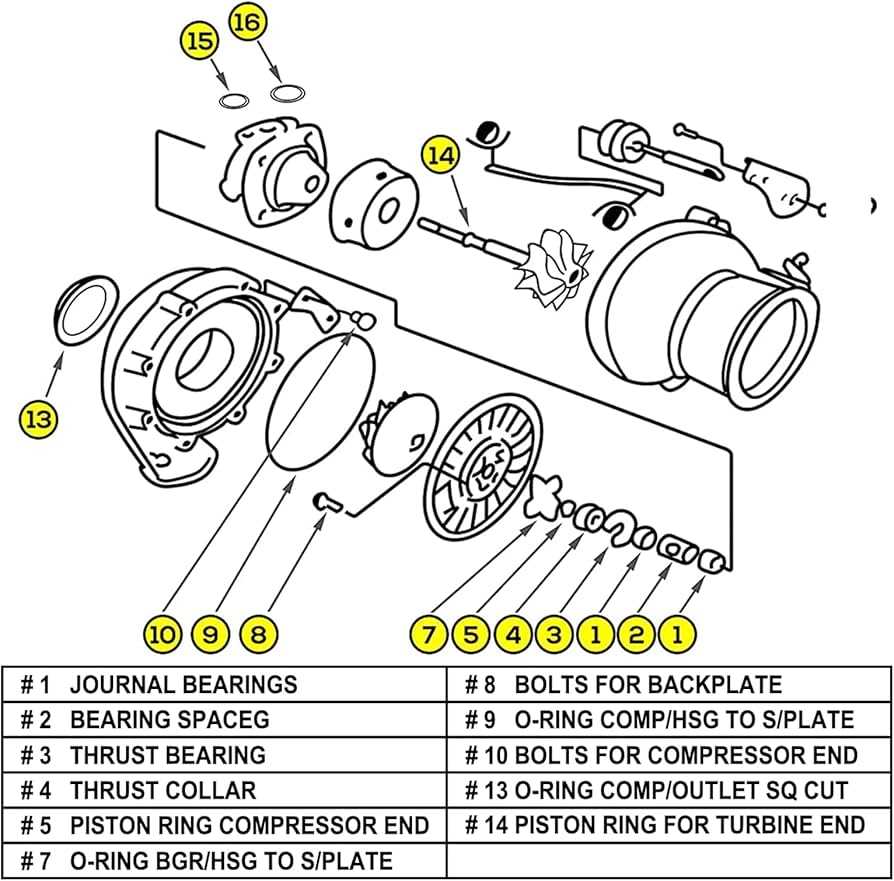

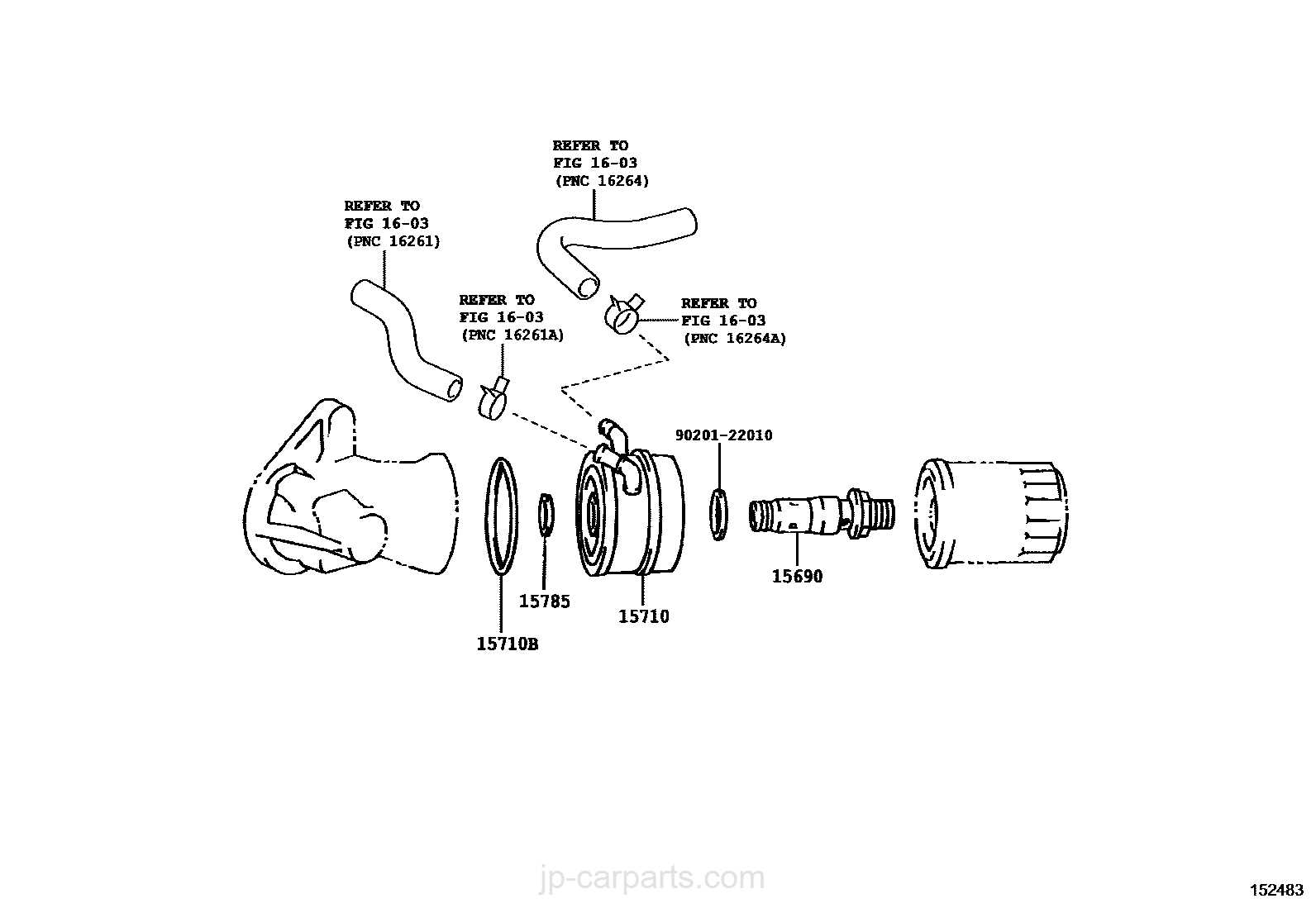

How to Read an Engine Schematic

Interpreting an engine schematic is an essential skill for anyone working on a diesel engine. These detailed visuals provide a clear representation of how various components are arranged and connected. Understanding the layout can help identify potential issues, pinpoint areas that require maintenance, and simplify the repair process.

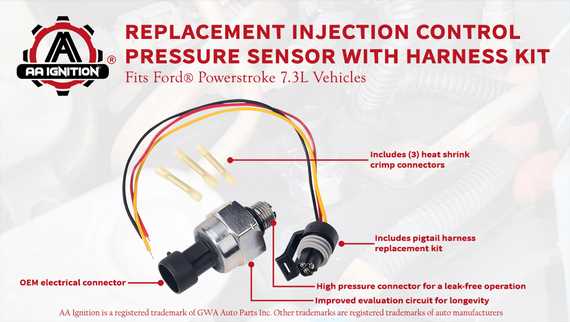

The first step in reading a schematic is familiarizing yourself with the symbols and labels used. Each part of the engine is represented by a specific icon or shape, often accompanied by a label for identification. Pay close attention to color codes and line styles, as they typically indicate the flow of fluids, electrical connections, or air circulation.

Once you understand the basic symbols, the next step is to trace the connections between different components. Follow the lines to see how fuel, air, and exhaust gases move through the system. This will give you a clear understanding of the engine’s operational flow, helping you spot any disruptions that could affect performance.

Lastly, it’s important to use the schematic in conjunction with manufacturer guidelines and technical manuals. These resources provide further context and specifications, allowing for more accurate diagnostics and repairs. By mastering how to read these diagrams, you’ll be better equipped to maintain and troubleshoot the engine efficiently.