Understanding the various components of your garden machinery is essential for its proper functioning and longevity. A well-organized guide to these elements helps you identify and troubleshoot potential issues quickly. Whether you’re conducting routine checks or performing repairs, having a clear overview of the machinery layout can save time and effort.

In this section, we will delve into the critical elements that make up this type of outdoor equipment. By becoming familiar with each piece, you can ensure your tools remain in top condition. A visual representation of the different segments will enhance your understanding and improve the maintenance process.

Proper maintenance is key to extending the lifespan of your equipment, and understanding how each component fits together is a crucial step. Whether you’re an experienced user or new to gardening tools, this information will guide you in the right direction, making upkeep simpler and more effective.

Understanding Garden Equipment Components

Every piece of outdoor machinery is composed of various sections that work in unison to provide effective operation. Understanding how these elements function together is essential for proper maintenance and troubleshooting. Identifying each component’s role helps users ensure the equipment runs smoothly and lasts longer.

Key segments of these tools include the engine, handles, and moving parts, all of which must be in good working order to achieve optimal performance. Regular inspection of these components can prevent common issues, such as wear or misalignment, which could lead to costly repairs.

Additionally, having a clear understanding of the structure and layout of each component makes it easier to replace or repair individual parts when needed. Knowledge of each element’s function allows users to efficiently address malfunctions and extend the overall lifespan of their equipment.

Identifying Key Parts of the Garden Equipment

Knowing the essential components of your outdoor machine is crucial for maintaining its functionality and ensuring it operates efficiently. Each section plays a specific role in achieving the desired results, whether it’s for cultivating soil, handling tough terrain, or simply ensuring smooth operation. Recognizing these components allows users to pinpoint issues more effectively and perform necessary adjustments or repairs.

Among the primary elements of such machinery are the motor, control handles, and rotating mechanisms, all of which work together to provide power and maneuverability. Understanding the structure of these parts helps in troubleshooting and routine maintenance, minimizing the risk of damage or malfunction.

By becoming familiar with the key elements, you’ll be able to address problems promptly and keep your equipment in peak condition for longer periods. This knowledge also aids in making the process of replacing worn-out parts quicker and more accurate, ultimately improving the overall user experience.

How to Use the Components Overview Effectively

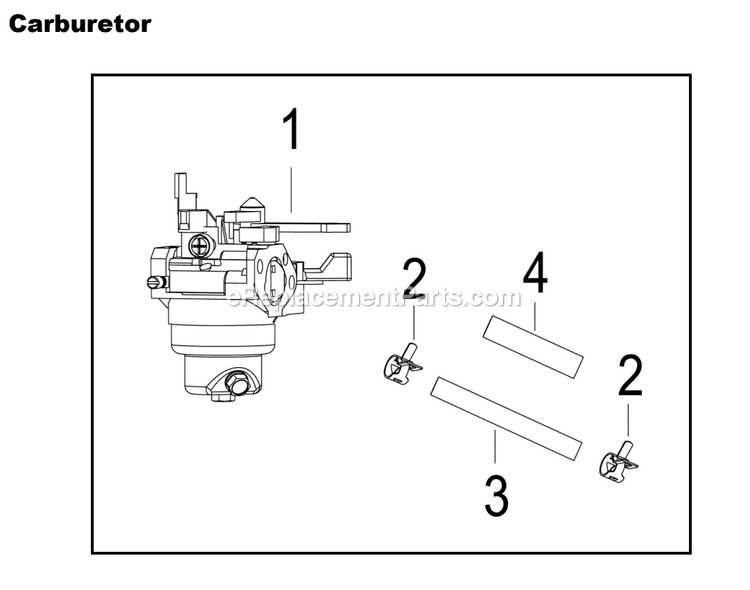

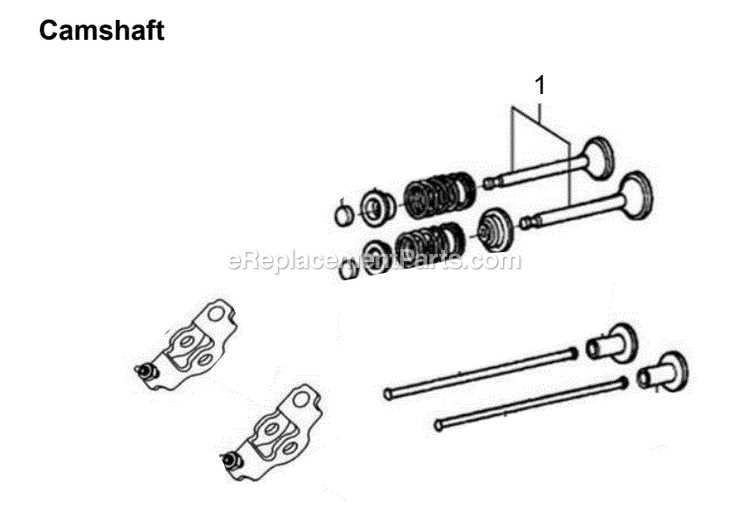

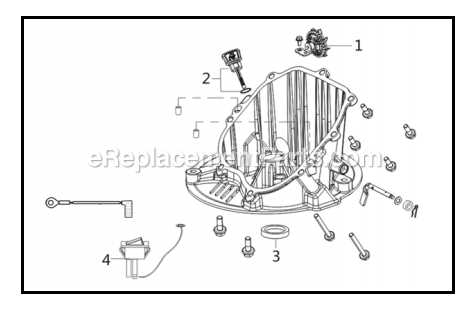

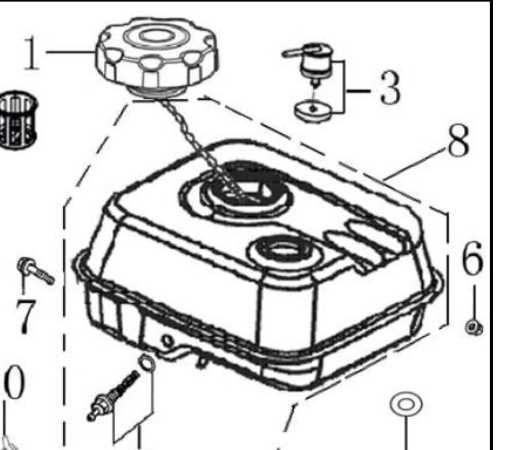

Having a visual guide of your equipment’s structure is an invaluable tool when performing maintenance or repairs. It allows you to clearly identify the individual sections and understand how they fit together, simplifying the process of troubleshooting and part replacement. By effectively using such a guide, you can save both time and effort while ensuring that each piece of machinery functions optimally.

Step-by-Step Identification

Start by closely examining each section of the guide to familiarize yourself with the layout and parts. Begin by identifying the major components, such as the engine or controls, before moving on to the smaller, more intricate sections. A clear understanding of each element’s position and function is crucial for addressing any issues effectively.

Utilizing the Guide for Repairs

When a problem arises, refer to the guide to locate the affected part and assess its condition. The visual representation helps you quickly spot the component in question and determine whether it needs repair or replacement. This efficient method allows for quick interventions, reducing downtime and improving overall maintenance procedures.