Efficient operation and maintenance of mechanical systems rely heavily on understanding the structure and individual elements that make up their design. Familiarity with these elements helps technicians and operators ensure longevity and avoid unnecessary breakdowns. By examining these key components, users can effectively troubleshoot issues and identify potential sources of malfunction.

Identifying each element is crucial for anyone involved in the maintenance or repair of hydraulic mechanisms. Whether for a new installation or a routine checkup, grasping the arrangement of various pieces provides insight into how the system functions as a whole. This knowledge is invaluable when addressing performance concerns or planning upgrades.

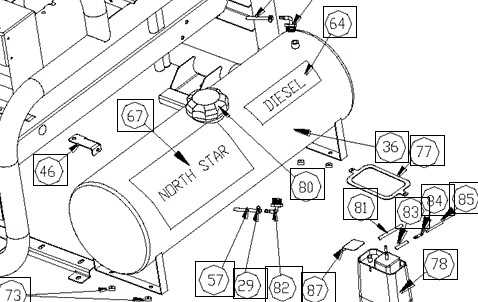

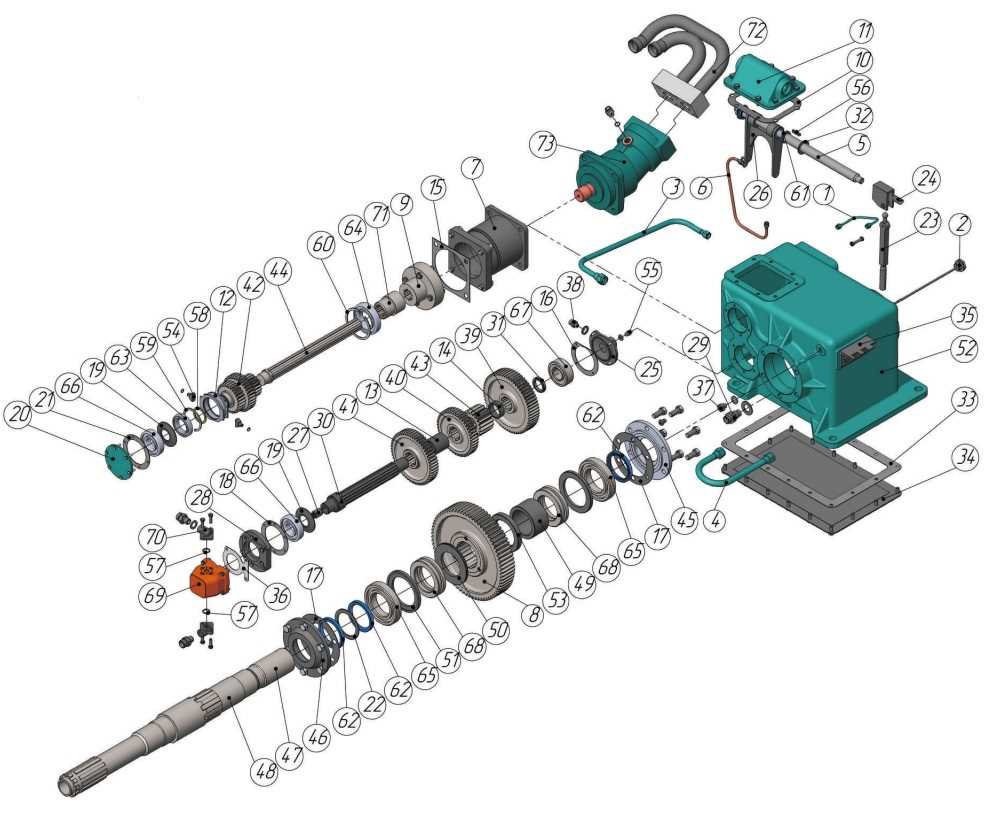

When dealing with intricate systems, having access to clear, detailed visuals aids in pinpointing the exact location and function of every part. By breaking down the layout of the system, operators can approach repairs with confidence, ensuring that each part is correctly aligned and optimized for maximum efficiency.

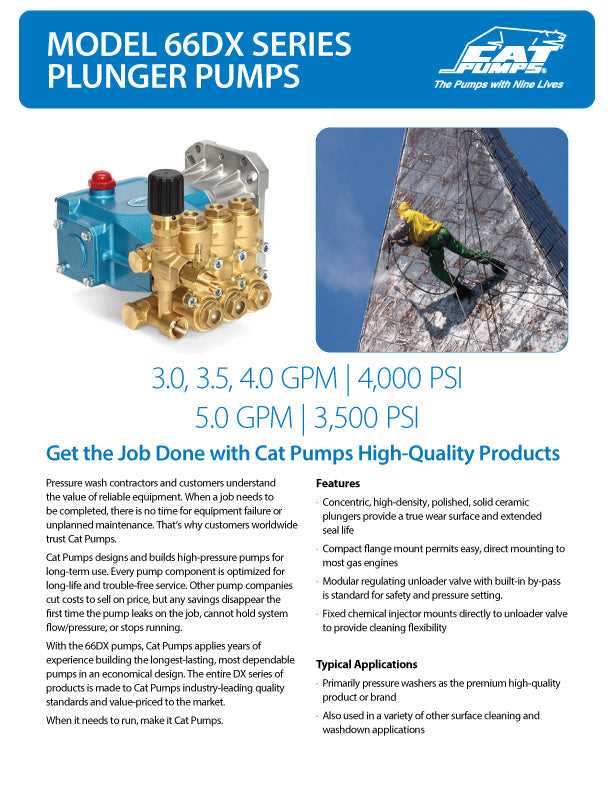

Understanding Cat Pump 66DX40G1 Parts

In any complex mechanical system, a clear understanding of its individual components is essential for proper maintenance and repair. Knowing how each element functions and interacts within the assembly ensures optimal performance and helps prevent issues that may arise from wear and tear. By focusing on the layout and roles of different segments, users can easily identify when something requires attention or replacement.

Key Components and Their Functions

Each segment within the system plays a vital role, whether it is responsible for fluid movement, pressure regulation, or structural integrity. Identifying these elements and understanding their functions in the larger mechanism is crucial for both troubleshooting and enhancing performance. Common parts such as seals, pistons, and valves all work together to ensure smooth operation under varying conditions.

Common Signs of Wear

Like any mechanical setup, the components may experience degradation over time due to constant use. Signs of wear can manifest in various forms, from leaking fluids to abnormal noises during operation. Regular inspections and knowledge of how each part should function can help quickly identify problems and mitigate further damage.

How to Read the Parts Diagram

To effectively work with complex mechanical systems, understanding how to interpret technical visuals is crucial. These illustrations provide a clear layout of the various components and their respective functions. Learning to read these visuals enables technicians to easily locate specific segments, identify their connections, and determine their roles within the overall system.

When examining such diagrams, there are a few key aspects to consider:

- Labels: Each component is typically labeled with a unique identifier, helping users quickly locate it in the visual.

- Lines and Connections: Lines between components often represent physical or functional connections. Understanding these helps in visualizing how parts interact with each other.

- Symbols: Specific symbols are used to denote different types of components, such as valves, seals, or cylinders. Familiarity with these symbols is essential for interpretation.

By following these guidelines, technicians can easily interpret visuals, which greatly improves their ability to carry out repairs, replacements, and adjustments.

Common Issues and Fixes for Cat Pumps

Mechanical systems are subject to wear and tear over time, and common issues may arise, affecting performance. Recognizing these issues early and addressing them promptly can prevent further damage and ensure smooth operation. Identifying typical problems and knowing how to resolve them is essential for maintaining the system’s efficiency and longevity.

Leaks and Fluid Loss

One of the most common issues in hydraulic systems is leakage. This can occur due to worn seals or improperly fitted components. To resolve this, it is essential to replace damaged seals and ensure all connections are securely tightened. Regular inspection of seals and hoses can help prevent such issues before they escalate.

Decreased Efficiency and Pressure Issues

If the system begins to show signs of reduced pressure or slower performance, it may indicate blockages or faulty valves. Cleaning the internal components and checking for debris buildup can often resolve these problems. If the issue persists, inspecting and replacing malfunctioning valves or pressure regulators may be necessary to restore optimal performance.