Every mechanical system relies on a precise arrangement of elements working together to ensure optimal performance. For efficient operation, it’s crucial to understand how each individual component fits within the larger assembly. Knowing how the various pieces interact can help with maintenance, troubleshooting, and repairs.

When examining these systems, it’s important to familiarize yourself with the layout and specific roles of each component. This knowledge not only simplifies identification of faults but also allows for informed decision-making when it comes to replacing or repairing specific parts. Proper understanding can prevent unnecessary downtime and improve the longevity of the equipment.

In this guide, we will walk through the essential elements of a typical pump system, highlighting their functions and providing insight into how they contribute to overall efficiency. Whether you’re a technician or a DIY enthusiast, mastering the fundamentals will give you confidence in maintaining or upgrading your equipment.

Understanding Pump System Components

In any mechanical assembly, each element serves a distinct role, contributing to the overall function of the unit. A thorough understanding of how each piece operates individually and collectively is vital for effective maintenance and troubleshooting. By familiarizing yourself with the key components, you can quickly identify potential issues and take the necessary steps to ensure optimal operation.

The system is comprised of various integral pieces that work in harmony to transport fluids efficiently. From the central drive mechanism to auxiliary elements, each part plays a specific role in the fluid movement process. Understanding the interaction between these components allows for better decision-making when diagnosing malfunctions or replacing worn-out items.

With knowledge of these essential elements, users can easily assess the condition of their equipment, carry out repairs when needed, and improve the longevity of the system. This understanding also provides valuable insight into how different configurations affect performance, enabling users to optimize setups based on their unique needs.

How to Read a Parts Blueprint

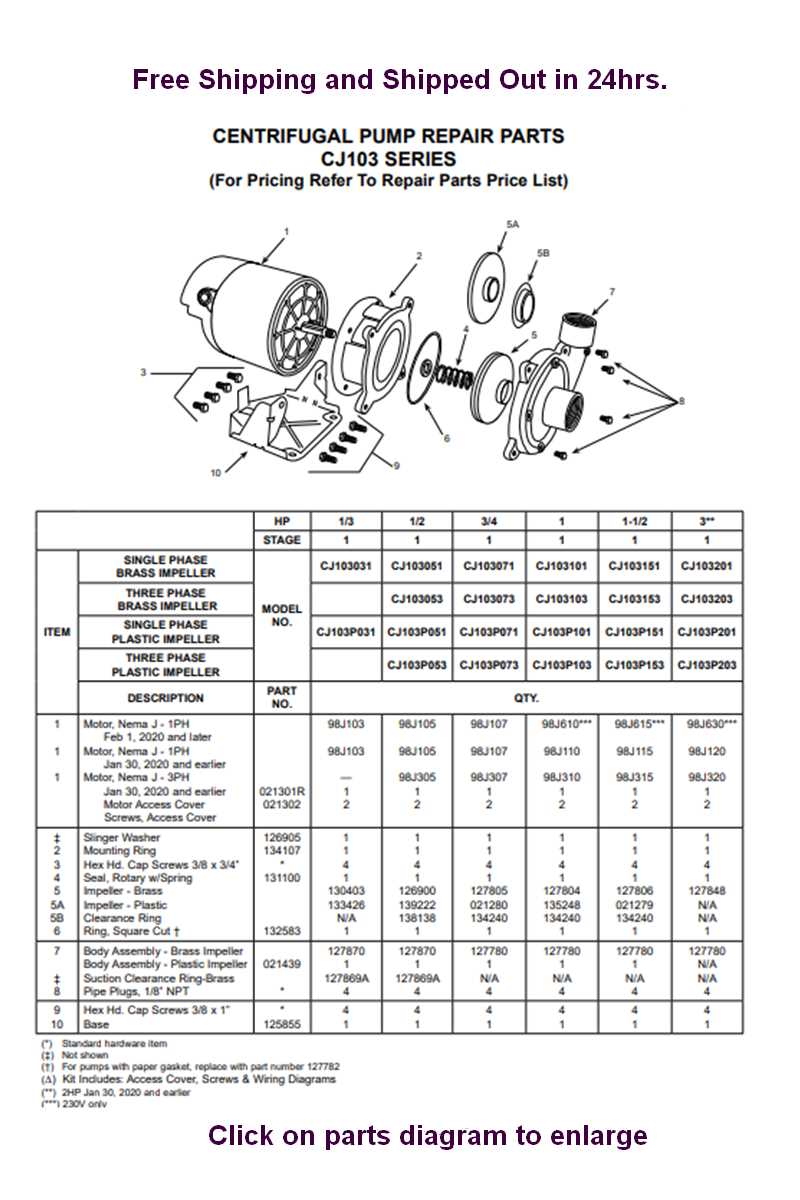

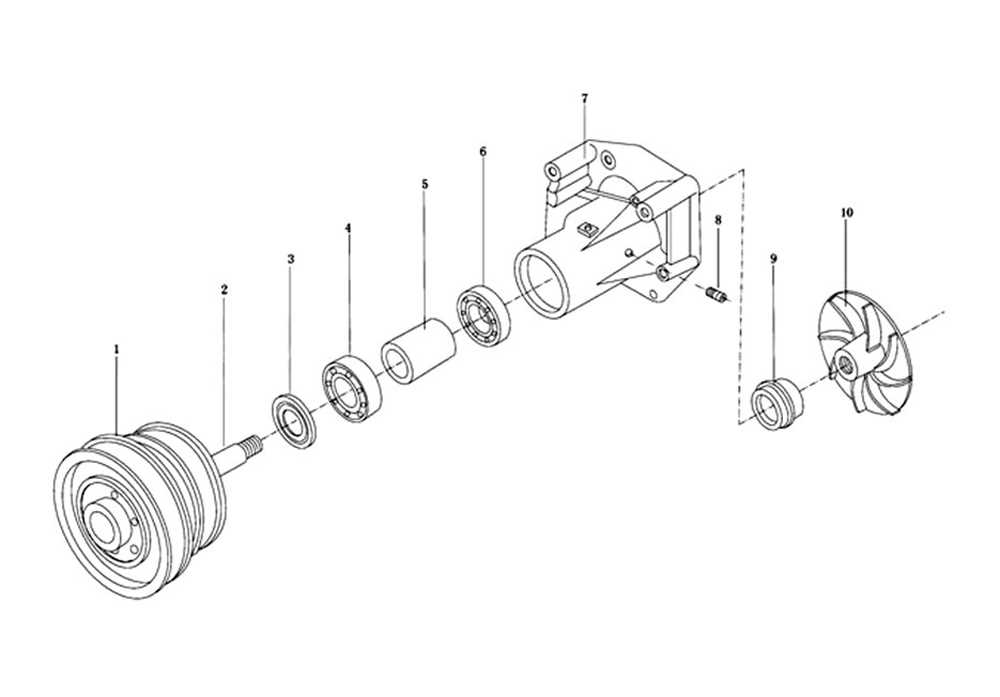

Understanding a system’s blueprint is essential for proper assembly, maintenance, and repair. These illustrations provide a detailed view of the components and their arrangement, allowing users to pinpoint specific parts and their functions within the larger mechanism. Mastering how to interpret these visual guides enables more efficient troubleshooting and part replacement.

Blueprints typically use a combination of symbols, lines, and annotations to represent each element. Each part is numbered or labeled for easy identification, and the connections between components are clearly shown. Reading the labels is key to recognizing which parts are relevant for your task, whether you’re replacing a faulty element or conducting regular maintenance.

To fully understand the blueprint, focus on the key sections: first, the main assembly layout, followed by the detailed parts list. Pay attention to the scales, as they indicate the relative sizes of components. Additionally, understanding the orientation of the system and any directional arrows will help in visualizing how each piece fits within the setup.

Common Issues with Mechanical System Components

Like any complex machinery, mechanical assemblies are prone to wear and tear over time. Regular use, environmental conditions, and lack of maintenance can cause certain parts to degrade or malfunction. Identifying these common issues early can prevent further damage and reduce downtime. It is important to recognize typical problems that can arise with the key elements of the system.

Worn Seals and Gaskets

One of the most frequent issues is the deterioration of seals and gaskets. These components are essential for maintaining proper sealing and preventing leaks. Over time, exposure to heat, pressure, and chemicals can cause these parts to lose their effectiveness, leading to leakage or loss of efficiency. Regular inspection can help catch this problem before it becomes critical.

Clogged or Damaged Impellers

Impellers are crucial for moving fluids within the system. However, they are often susceptible to damage from debris or corrosion. A clogged or damaged impeller can cause a significant drop in performance, resulting in reduced flow rates or complete failure. Proper cleaning and regular checks of the impeller can mitigate these issues.