In any mechanical system, it is essential to comprehend how different elements work together to ensure proper functioning. The relationship between various parts determines the overall efficiency and longevity of the entire unit. A clear understanding of these components can help users identify issues, perform maintenance, and optimize performance.

By exploring the key elements of the system and how they interact, users can gain insights into its structure and operations. Whether it’s troubleshooting or upgrading, knowing the roles of each part provides a solid foundation for effective handling and care.

Knowledge of the system’s layout allows for more informed decisions and better problem-solving. The importance of clear representation and labeling cannot be overstated, as it simplifies identifying potential faults and planning repairs or improvements.

Understanding the System Components

Each mechanical system consists of various interconnected elements that work together to ensure smooth operation. The key to maintaining efficiency and avoiding malfunctions lies in understanding how these components function individually and in relation to each other. A proper grasp of their roles enables more effective troubleshooting and maintenance.

The main components include those responsible for the intake, filtration, and output processes, as well as those that regulate flow and ensure proper movement of fluids through the system. Each part plays a crucial role in the overall performance, and identifying them is essential for successful management.

Recognizing the function and placement of each element makes it easier to identify potential issues, allowing for targeted repairs and adjustments. This understanding not only simplifies maintenance tasks but also ensures that the system continues to operate optimally over time.

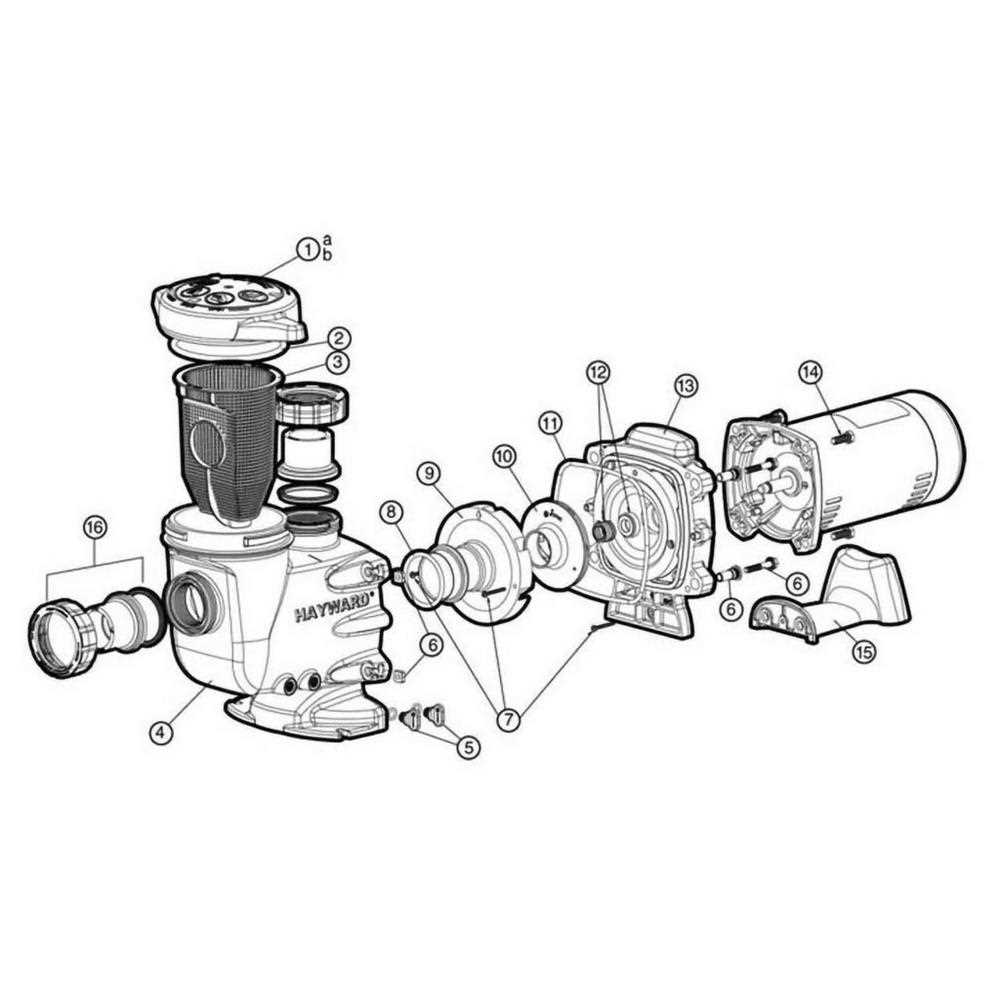

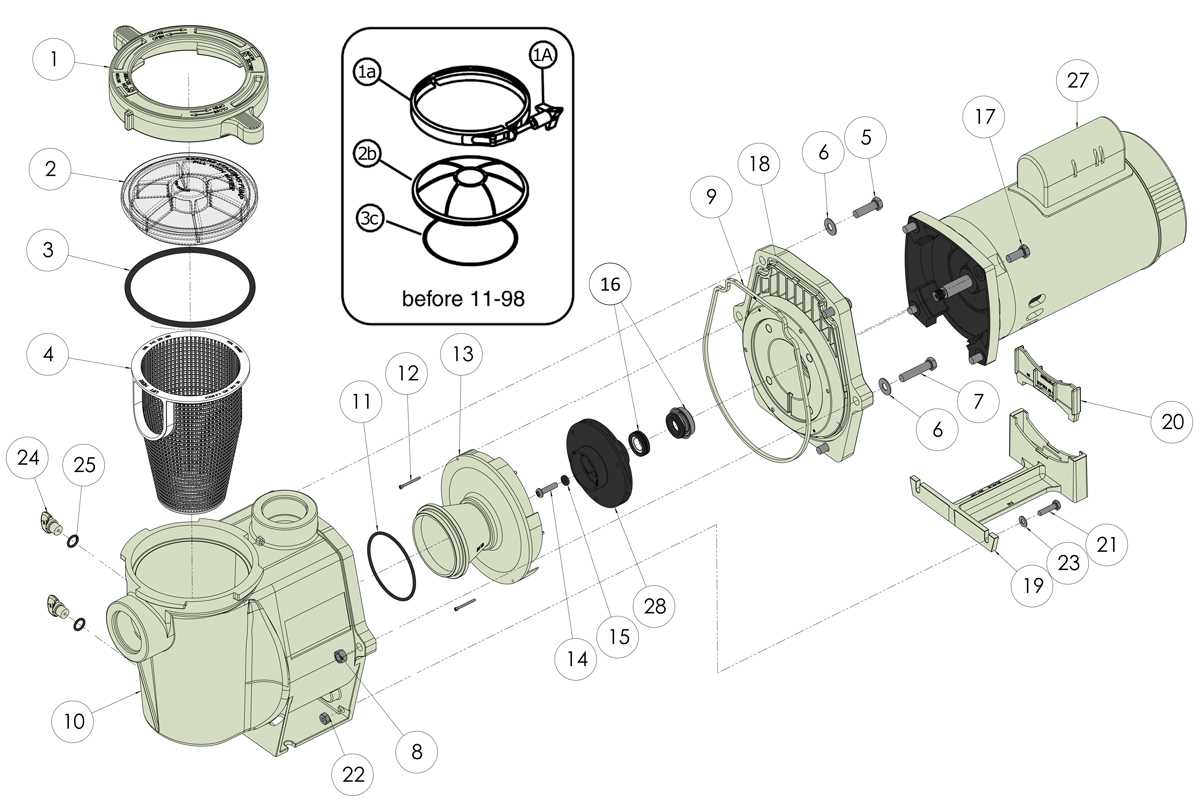

Key Parts of the System

A system relies on several critical components that facilitate its overall functionality. These essential elements work together to ensure smooth operation and efficient performance. Understanding these parts helps in troubleshooting, maintenance, and optimizing the system for long-term use.

The main components include the motor, which drives the system’s movement, and the filter, which ensures the proper flow and cleanliness of the fluid. Additionally, there are components responsible for regulating pressure and controlling the flow rate, which are essential for maintaining stability and preventing damage to the system.

By recognizing the purpose and function of each part, users can easily identify any weaknesses or issues that may arise. This knowledge is important for making informed decisions about repairs, replacements, and general upkeep.

How to Interpret the System Layout

Understanding the layout of a system is essential for identifying each component and its role. A clear visual representation provides valuable insight into how the elements connect and function together. Interpreting these layouts accurately is crucial for effective maintenance and troubleshooting.

When examining a layout, start by recognizing the main components, such as the motor and the flow pathways. Focus on the connections between parts, as they often indicate the direction of movement and interaction. Each symbol or label is designed to help you easily pinpoint the exact location and function of each element.

By carefully studying the diagram, it becomes easier to understand the system’s behavior and predict potential issues. The more familiar you are with the layout, the more efficient your maintenance and repairs will be. This knowledge allows for faster problem-solving and more precise adjustments, ensuring the system operates at its best.