When it comes to maintaining and repairing your filtration system, knowing the different elements that make up the equipment is crucial. Identifying each component’s role will help ensure proper operation and efficiency. Understanding these essential elements empowers users to carry out effective troubleshooting and maintenance tasks.

In this section, we will explore the key components of the system, focusing on how they interact with one another. By breaking down each piece, you will gain insights into how they contribute to the overall functionality. With this knowledge, you can better assess any issues and perform timely repairs or replacements as needed.

Effective maintenance relies on a clear understanding of the setup, and this guide will provide the necessary information to make it easy to navigate through the intricate details of the system. Whether you’re a professional or a DIY enthusiast, learning about these crucial components will enhance your ability to keep the system running smoothly for years to come.

Understanding the Equipment’s Key Elements

Grasping the structure and functioning of a filtration unit is essential for proper maintenance. This understanding allows for more efficient troubleshooting and ensures that each component is performing its intended task. The machine’s elements work in unison to facilitate water movement and filtration, with each part playing a vital role in the system’s overall effectiveness.

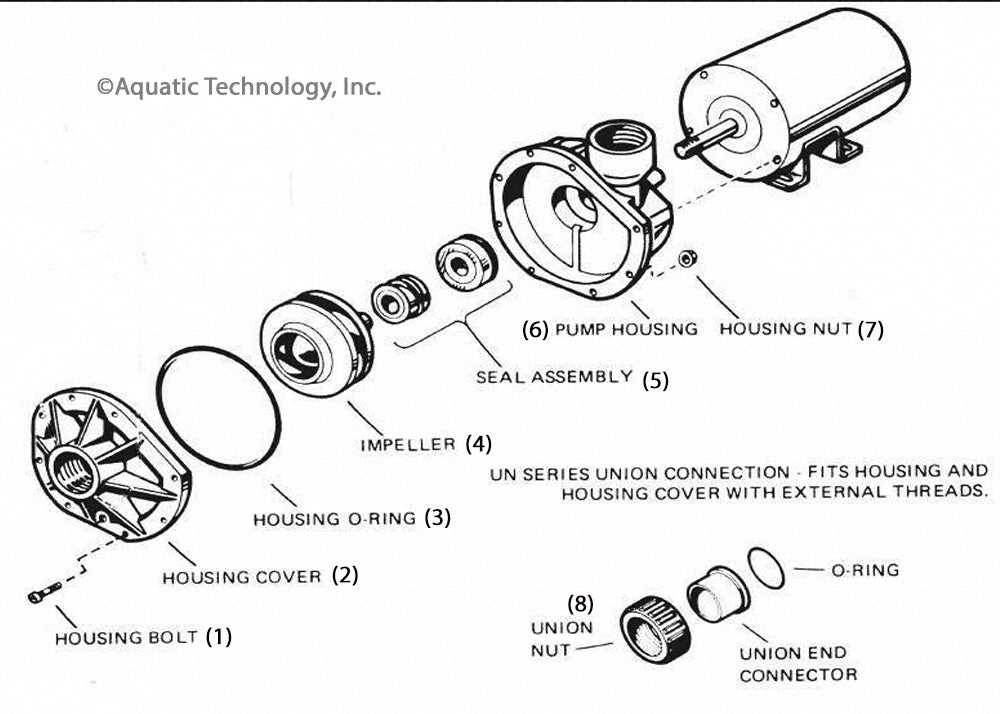

Main Components and Their Functions

- Housing: The outer shell that protects the internal components and keeps them securely in place.

- Impeller: A rotating device that pushes water through the system to maintain flow and circulation.

- Capacitor: A small electrical component that helps start and run the system efficiently by storing energy.

- Seal: Prevents water from leaking into other parts of the system and ensures long-term durability.

- Bearings: Support the moving parts of the system and reduce friction to enhance performance.

How These Components Work Together

The elements listed above collaborate to keep the filtration system functioning smoothly. The housing holds everything in place, while the impeller pushes the water through, assisted by the capacitor’s energy storage. Seals prevent unwanted leaks, and bearings ensure smooth operation of moving components. By understanding how these parts interact, users can easily pinpoint issues when they arise and address them efficiently.

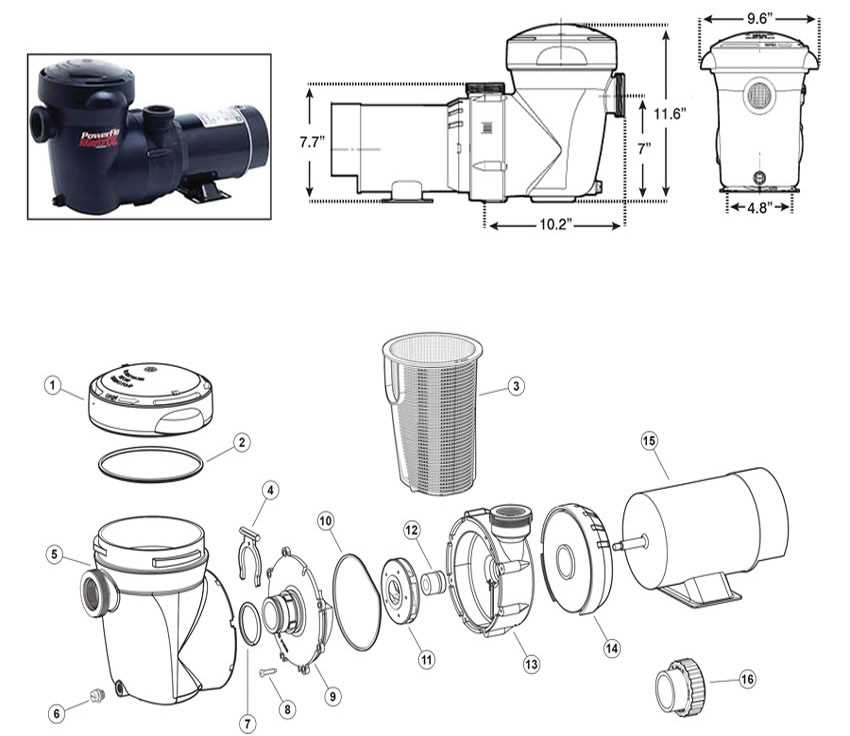

Key Components of the Pump Motor

Each element of the system serves a specific function, working together to maintain the efficiency of the entire setup. Understanding these essential components helps ensure the longevity and proper functioning of the system. When you are familiar with each part, it’s easier to detect issues early and perform the necessary repairs or replacements.

Essential Elements of the System

- Housing: The protective casing that holds all internal components securely in place.

- Impeller: The rotating piece that moves water through the system, creating the necessary flow.

- Capacitor: Stores electrical energy to assist with the starting process and maintain consistent performance.

- Seal: Prevents water from leaking and causing damage to the surrounding components.

- Bearings: Support the rotating parts, reducing friction and ensuring smooth operation.

How They Contribute to Efficiency

These components are designed to operate in harmony, ensuring optimal flow and minimizing wear. The impeller’s movement is supported by the housing, while the capacitor provides the initial energy to get the system running. The seals keep moisture contained, and bearings reduce the friction that can cause overheating. Together, they maintain the functionality and extend the lifespan of the entire unit.

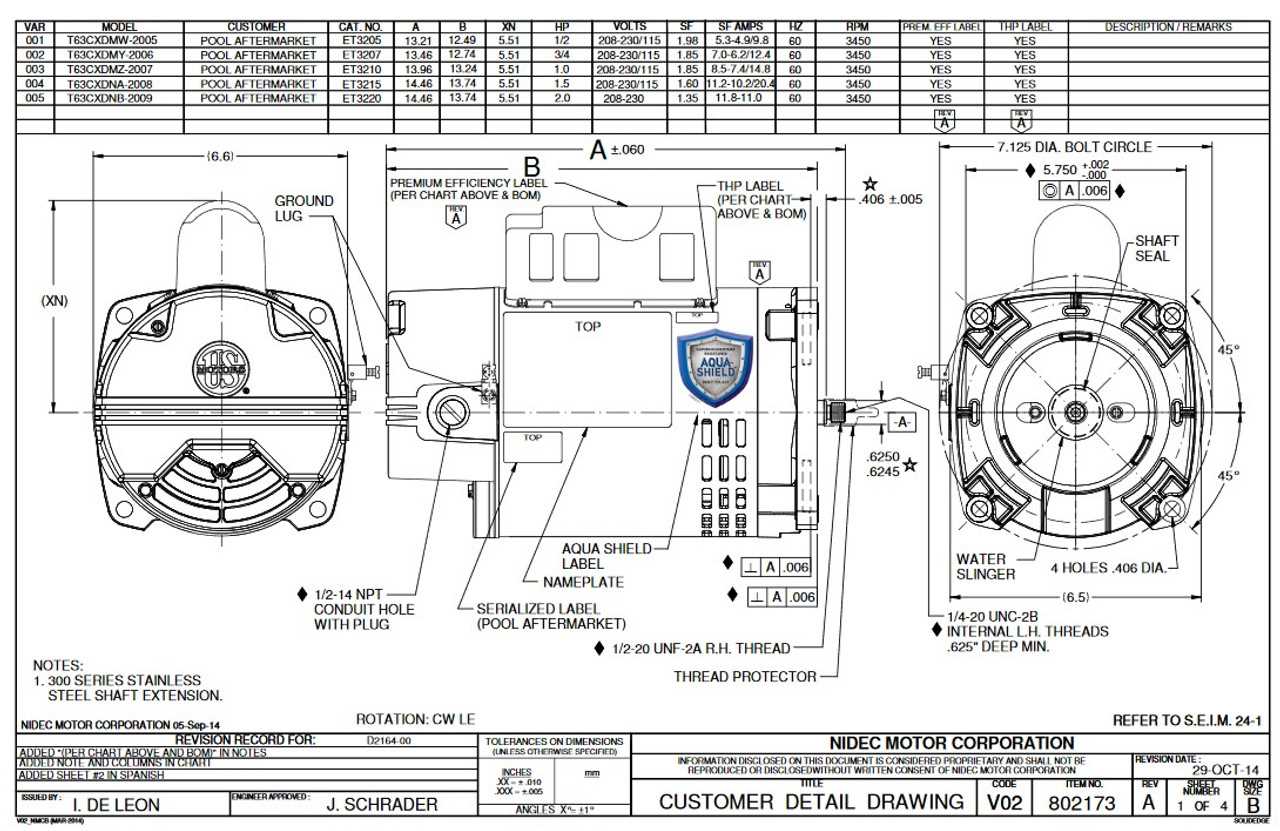

How to Use the Motor Diagram

Understanding how to read and apply the schematic of a system is crucial for effective troubleshooting and repair. These visual aids provide a detailed layout of the system’s internal components, making it easier to identify and address issues. Knowing how to use this diagram can save time and effort when performing maintenance or diagnosing problems.

Identifying Key Components

The first step in using the schematic is to familiarize yourself with the key components depicted. Each part will be labeled clearly, often with corresponding numbers or symbols, to help you match them with physical parts in the unit. By recognizing each piece’s location and role, you can quickly determine where a malfunction may be occurring.

Step-by-Step Troubleshooting

Once you’ve identified the components, follow the flow of the system as shown in the diagram. Start by checking the elements that are most likely to fail, using the visual guide to trace connections and locate areas where wear or damage might have occurred. This systematic approach will help you isolate issues, ensuring that repairs are targeted and effective.