When it comes to maintaining and troubleshooting water systems, understanding the internal structure of your equipment is essential. Whether you are replacing a malfunctioning component or simply performing routine upkeep, knowledge of each element’s role will help ensure efficiency and longevity.

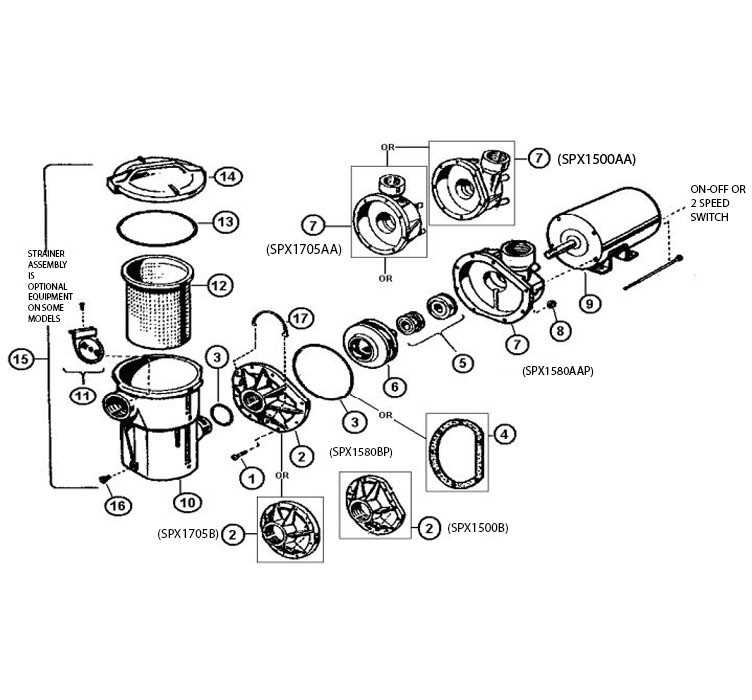

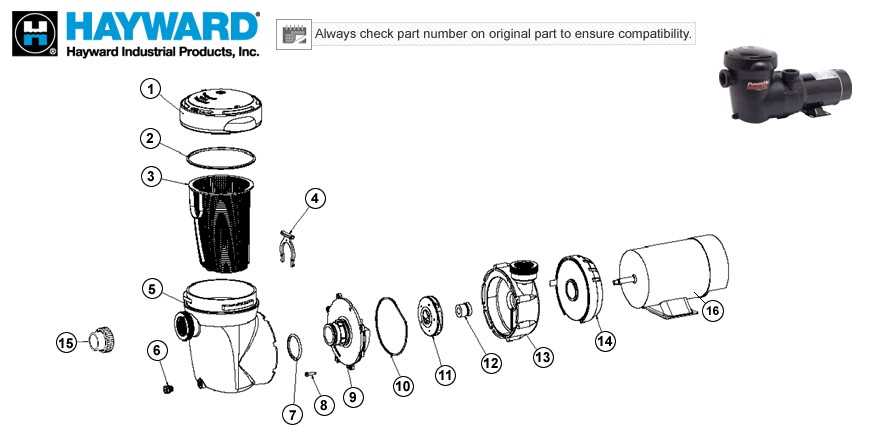

The internal assembly consists of various elements, each contributing to the overall functionality. Identifying the right components and understanding their specific functions can simplify repairs and prevent future issues.

By examining the detailed layout of the system, you can easily pinpoint which sections need attention. Accurate identification of issues leads to more effective maintenance, helping you avoid unnecessary delays and reduce the chances of further damage.

Understanding Key Components of Your Equipment

Proper maintenance of your water system relies on recognizing and understanding the various elements within its structure. Each part plays a unique role in ensuring smooth operation and preventing performance issues. Familiarity with the key components allows you to diagnose problems effectively and perform necessary repairs.

The system is made up of several interconnected units, each with specific functions. From the motor to the intake and outflow sections, each component is essential for maintaining proper water flow and pressure. A detailed understanding of how these components work together helps in troubleshooting and minimizing downtime.

Knowing the layout and purpose of each part also simplifies the process of replacing damaged or worn-out sections. By identifying the malfunctioning components, you can restore the system’s efficiency without unnecessary replacements or repairs.

Identifying Key Parts and Functions

To maintain the efficiency of your water circulation system, it is crucial to identify the core components that drive its operation. Understanding what each part does allows for better troubleshooting and ensures that the system continues to function optimally. Each element serves a specific purpose, contributing to the overall flow and pressure management.

Motor and Its Role

The motor is the powerhouse of the system, converting electrical energy into mechanical force to drive the water flow. Its performance is critical to the system’s efficiency, and any issues with it can lead to a lack of pressure or failure to circulate water properly.

Intake and Discharge Units

Intake and discharge units regulate the flow of water into and out of the system. These units ensure that water enters and exits at the correct rate, preventing overflows or insufficient pressure. Proper alignment and maintenance of these units are vital to maintaining stable system performance.

How to Troubleshoot and Replace Components

When your water circulation system encounters issues, troubleshooting and replacing malfunctioning components becomes essential for restoring proper function. By systematically checking each part, you can pinpoint the source of the problem and determine if a replacement is necessary. This process helps avoid unnecessary repairs and keeps your system running efficiently.

Step-by-Step Troubleshooting

Begin by inspecting the motor, intake, and discharge units for any signs of damage or wear. Common issues like poor water flow, unusual noises, or lack of pressure are often indicators of problems with these critical components. Checking for blockages or loose connections can often resolve simple issues.

Replacing Worn or Damaged Components

If any part is found to be damaged, replacing it with a compatible component is key. Ensure that the new part matches the specifications of the original to maintain system performance. Carefully follow manufacturer guidelines for proper installation to avoid misalignment or further damage.