When it comes to maintaining a functional and efficient pool system, knowing the essential elements that make up the machinery is crucial. Each part plays a specific role in ensuring smooth operation, and being familiar with their functions can help avoid common issues and costly repairs.

From the motor to the smaller internal elements, every component is designed to work together. In order to keep everything running optimally, it is important to understand the structure and function of each piece. This knowledge empowers owners to troubleshoot problems, perform routine maintenance, and replace damaged components as needed.

Recognizing the signs of wear and tear in the system and knowing how to address them can make a significant difference in the longevity and performance of your equipment. Regular inspection and timely action can prevent minor problems from escalating into major breakdowns.

Whether you’re a first-time owner or have years of experience, having a clear understanding of the layout and connections of the system is key. By taking the time to familiarize yourself with each element, you can ensure your pool’s machinery continues to function efficiently and safely.

Understanding Pool Equipment Components

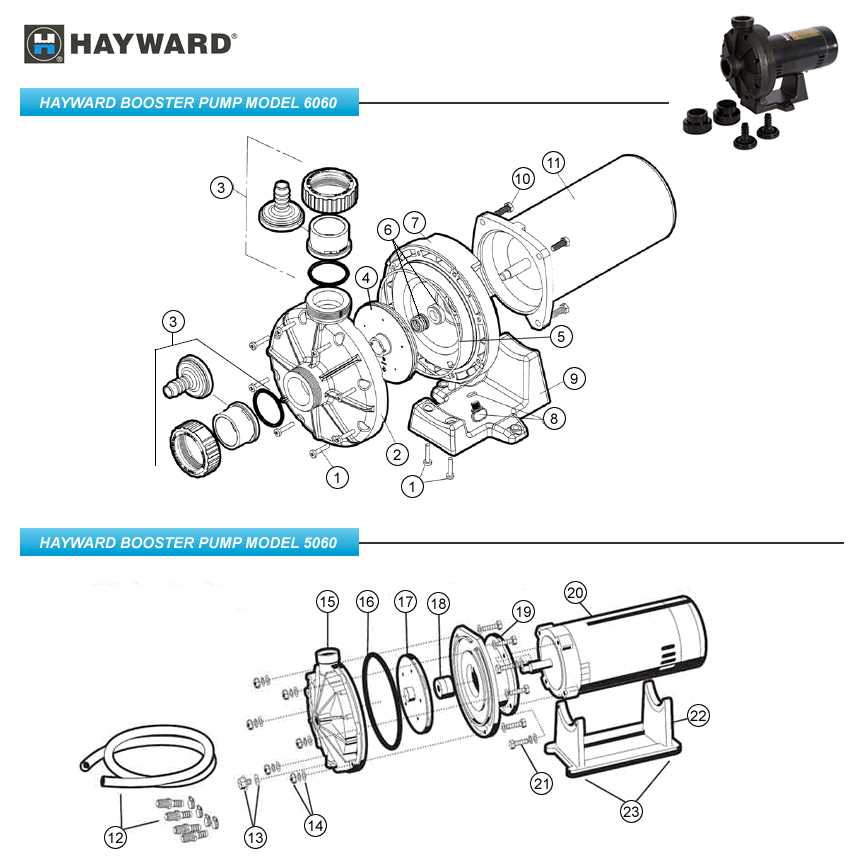

The effective operation of a pool system relies on the integration of various components, each with a specific function. These elements work together to ensure proper circulation and filtration, ultimately contributing to the overall efficiency of the system. Familiarity with each component allows owners to identify issues quickly and perform necessary maintenance.

The motor is one of the central elements, providing the necessary power to drive the entire system. Surrounding it are key parts that regulate water flow, filtration, and circulation. Understanding how each part contributes to the process will help you troubleshoot and optimize the equipment for longevity and peak performance.

Components such as the strainer, impeller, and housing are all crucial for maintaining proper flow and preventing clogs. Each of these elements plays a role in ensuring that the system remains free of debris and operates without interruption. Regular inspection of these items is essential for smooth operation.

Knowing the general layout and function of the system components ensures that owners are well-equipped to make informed decisions regarding maintenance and repairs. Proper care of each element helps avoid premature wear and keeps the system running smoothly for years to come.

Common Issues with Pool Equipment Components

Over time, the different elements of a pool system can experience wear and tear, leading to various operational problems. Recognizing the signs of common issues early on can prevent larger, more costly repairs. Understanding the most frequent problems helps pool owners maintain the system efficiently and avoid unnecessary downtime.

Some of the typical problems that arise include:

- Reduced water flow – This can be caused by clogs or obstructions in the system, such as debris in the intake or filters that need cleaning.

- Unusual noises – Grinding, rattling, or whistling sounds may indicate mechanical issues, such as worn bearings or a malfunctioning motor.

- Leaks – Leaks often occur around seals or fittings, leading to water loss and reduced efficiency.

- Inconsistent operation – Irregular or intermittent functioning could point to problems with electrical connections, wiring, or the control system.

Addressing these problems quickly and correctly is essential for maintaining the health of the system. Regular maintenance, including cleaning filters, checking for leaks, and inspecting the mechanical components, will help ensure smooth operation and extend the lifespan of your equipment.

How to Replace Pool Equipment Components

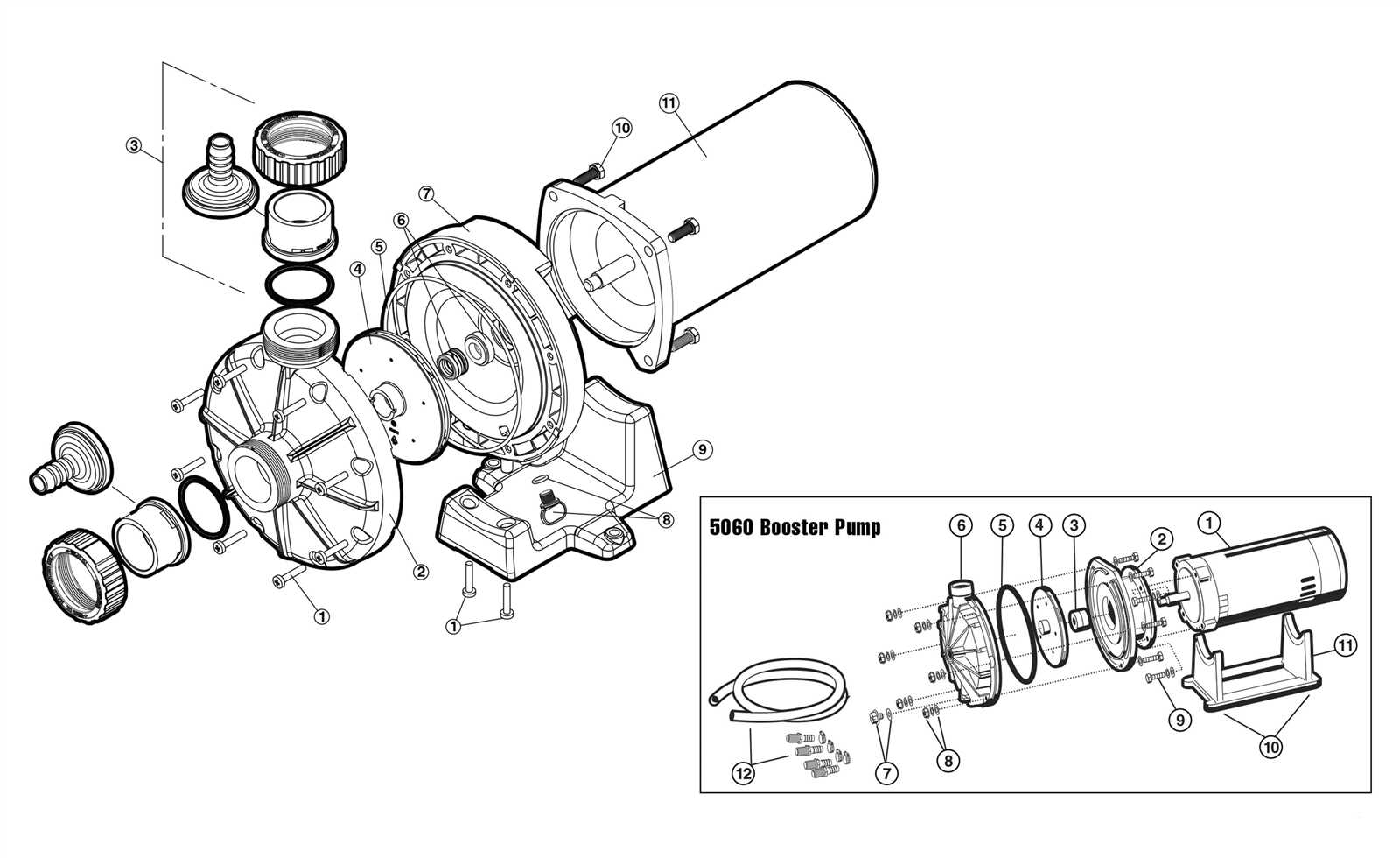

Replacing faulty elements of a pool system can restore its functionality and ensure optimal performance. While some tasks may seem complex, with the right tools and guidance, many components can be replaced with ease. Understanding the steps involved and taking precautions will help you complete the replacement efficiently and safely.

Step-by-Step Guide

Before starting any replacement, ensure the system is completely powered off and that water is drained to prevent accidents. Begin by identifying the faulty component, whether it’s a motor, impeller, or another element, and consult the manufacturer’s instructions for specific details on removal and installation.

Once the part is located, use appropriate tools to carefully remove any screws, bolts, or fasteners securing the element. Take note of the order and orientation of parts for easy reinstallation. After removing the defective component, position the new one carefully, ensuring it is aligned correctly. Secure it in place and check all connections before restoring power.

Testing and Final Adjustments

After the new part is installed, run the system briefly to ensure everything is functioning as expected. Listen for any unusual sounds, check for leaks, and verify that water flow is normal. If everything appears to be working well, perform a final inspection and reassemble any covers or panels.

Regularly replacing worn components and conducting maintenance will help keep the system running efficiently and prolong its lifespan.