Understanding Pump Component Functions

Maintenance Tips for Optimal Performance

High-Flo Gold Series Pump Overview

This section provides a detailed look into a high-performance fluid movement system designed for efficiency and durability. The mechanism is tailored to meet the demands of heavy-duty applications, ensuring seamless operation under various conditions. With a focus on reliability, the system integrates advanced engineering to handle demanding tasks with precision.

The unit is built with robust components that ensure long-lasting functionality and minimal maintenance. Each element is strategically designed to optimize performance, offering powerful flow rates and dependable output. Designed for both residential and industrial purposes, this system excels in areas requiring consistent and high-volume fluid circulation.

Special attention has been given to the materials and design structure, contributing to its efficiency and strength. Whether used in water systems, irrigation setups, or other fluid-based systems, the equipment ensures high operational standards with reduced energy consumption. This makes it a preferred choice for those seeking both power and sustainability in their operations.

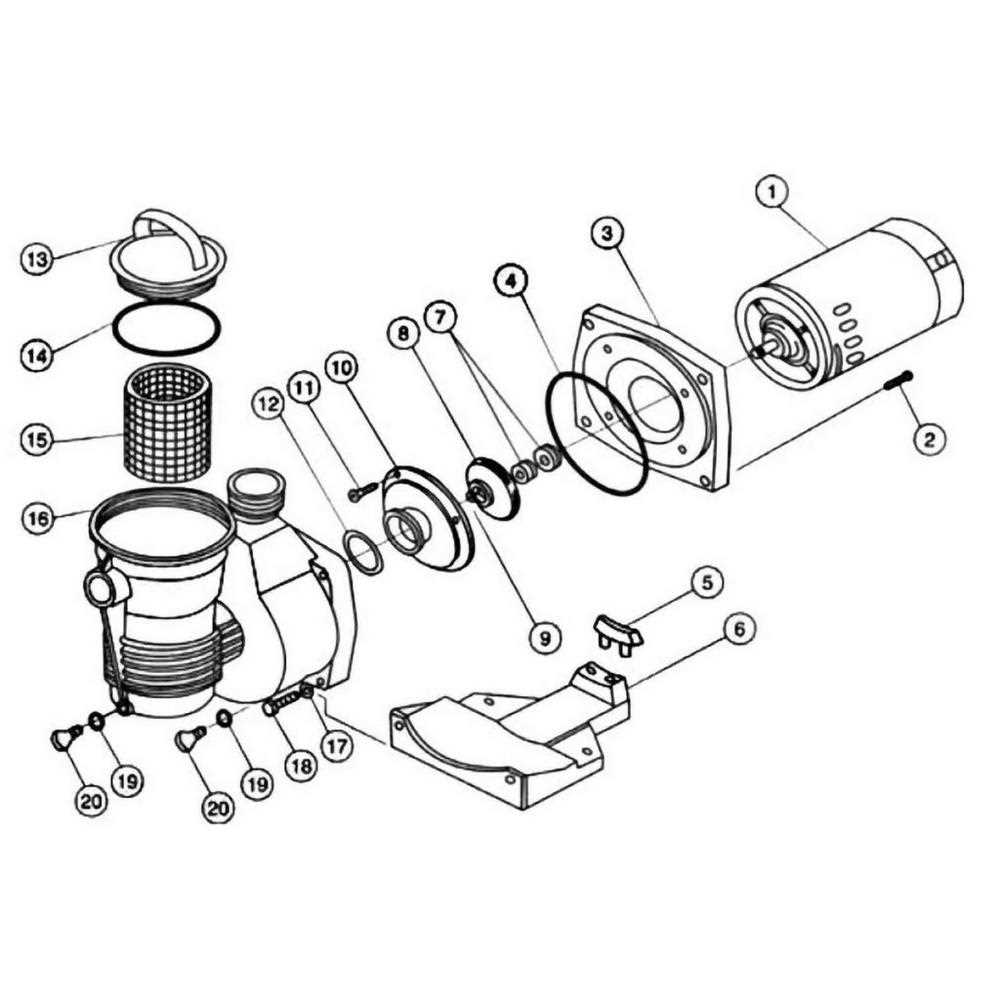

Understanding Key Pump Components

To fully grasp the functionality of a fluid circulation system, it is essential to understand the primary components that make up the entire mechanism. Each element plays a crucial role in ensuring efficient operation, contributing to the overall performance and reliability. These core parts work in harmony to achieve optimal flow and minimal wear, even under challenging conditions.

Core Elements of the System

At the heart of this system are the moving parts designed to facilitate the transfer of fluids with precision. The primary element ensures smooth fluid passage, maintaining constant pressure and volume. Components like seals and bearings are essential for minimizing friction and ensuring durability, while the casing provides structural integrity to hold the system together securely.

Supporting Features

In addition to the key moving components, various support features enhance efficiency. These include the mechanisms that regulate flow and control the direction of the fluid, ensuring stability throughout the operation. The combination of these elements creates a robust framework capable of handling high-demand tasks with minimal downtime.

Maintenance Tips for Pump Longevity

Proper care and regular maintenance are key factors in extending the lifespan of any fluid circulation system. Ensuring that the core components remain in good condition not only improves performance but also minimizes the need for costly repairs. A proactive approach to upkeep can significantly reduce downtime and maintain efficient operation over time.

Regular Inspections

Routine inspections are essential for identifying any signs of wear or damage. Checking the system for leaks, cracks, or signs of corrosion can help catch potential issues early. Ensuring that all connections are secure and that seals remain intact will prevent fluid loss and maintain optimal pressure levels. Regular inspections help avoid the need for extensive repairs down the line.

Cleaning and Lubrication

Keeping the internal components clean is crucial for preventing the buildup of debris or sediment that could impede functionality. Periodically cleaning the system and applying appropriate lubrication to moving parts helps reduce friction and ensures smooth operation. This simple maintenance step significantly contributes to the longevity and efficiency of the equipment.