Fuel delivery systems in engines are complex mechanisms that rely on precise coordination of multiple components to ensure optimal performance. These systems are responsible for regulating fuel flow and timing, ensuring the engine operates smoothly and efficiently. A proper understanding of these elements is crucial for maintenance and troubleshooting.

In this guide, we will break down the essential components that make up these systems, explaining their function and how they work together to achieve peak efficiency. Identifying these elements will allow technicians and enthusiasts alike to diagnose issues and perform necessary repairs with confidence.

Familiarizing yourself with the structure of these systems can save both time and resources. By analyzing the setup, it becomes easier to pinpoint problems and understand how each component plays a vital role in fuel delivery.

Understanding the Fuel Delivery System

The fuel delivery system plays a crucial role in ensuring that an engine receives the correct amount of fuel at the right time. This system is made up of several interconnected components that work together to manage the flow, pressure, and timing of the fuel injected into the engine. Each element must operate with precision to maintain engine performance and efficiency.

At the heart of this system is a mechanism that controls the flow of fuel, directing it to the correct parts of the engine based on the needs of the operation. Whether it’s starting the engine, maintaining optimal running conditions, or adjusting for varying speeds, this system constantly adapts to meet the demands of the engine’s operation.

Understanding how each component interacts within the system helps in troubleshooting common issues and performing effective repairs. Identifying the function of each part and how it contributes to the overall operation is essential for proper maintenance and extending the lifespan of the equipment.

Key Components of the Fuel Delivery System

The fuel delivery mechanism consists of various key elements that work together to ensure precise fuel distribution to the engine. Each component has a specific role, contributing to the overall functionality and efficiency of the system. These parts must function in harmony to regulate fuel pressure, timing, and flow to meet the engine’s operational requirements.

One of the most important components is the regulating device that controls the fuel flow, ensuring that the right amount is delivered under varying conditions. The timing mechanism plays a critical role in ensuring that fuel is introduced into the combustion chamber at the optimal moment for maximum performance.

Other crucial elements include the valves, seals, and pumps, all of which work together to maintain system integrity. Any malfunction in these components can disrupt the entire system, leading to engine inefficiency or failure. Understanding each part’s function is vital for troubleshooting and performing necessary repairs.

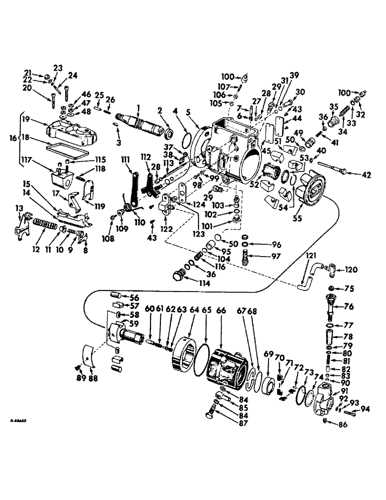

How to Read the Parts Diagram

Interpreting the visual layout of system components is essential for understanding the configuration and function of each element. A well-organized chart can serve as a guide for identifying parts, their placement, and how they interact within the entire system. Knowing how to read such diagrams makes troubleshooting and maintenance tasks much more manageable.

Identifying Key Elements

When reviewing a schematic, the first step is to recognize the key components. Each part will be labeled with either a symbol or a number, corresponding to a detailed description. Understanding these identifiers allows you to pinpoint the location and function of each element within the system.

Understanding Relationships Between Parts

The next step is to understand how these components connect and interact. A well-designed diagram will illustrate the flow of energy or material, showing how one part influences another. Paying attention to these relationships will help you grasp the system’s operation more clearly and identify potential problem areas.