When it comes to managing water flow in basements or low-lying areas, several essential elements work together to provide reliable protection. Each element plays a unique role, contributing to the efficiency and longevity of the system. By understanding these key components, homeowners can ensure their setup operates at optimal levels.

Effective management of water requires more than just basic equipment. It involves a detailed understanding of how different components interact to remove excess water and prevent flooding. Knowing how each piece functions and connects to the others is crucial for proper maintenance and troubleshooting.

In this guide, we will break down the various components involved, offering insight into their purpose and the impact they have on the overall system. This knowledge helps in identifying potential issues and making informed decisions regarding repairs or replacements.

Key Components of a Flood Control System

Effective water removal systems rely on several essential elements working in unison. These components are designed to ensure that excess water is efficiently redirected, keeping spaces dry and preventing damage. Each piece plays a specific role in maintaining the system’s reliability and functionality over time.

Primary Functional Elements

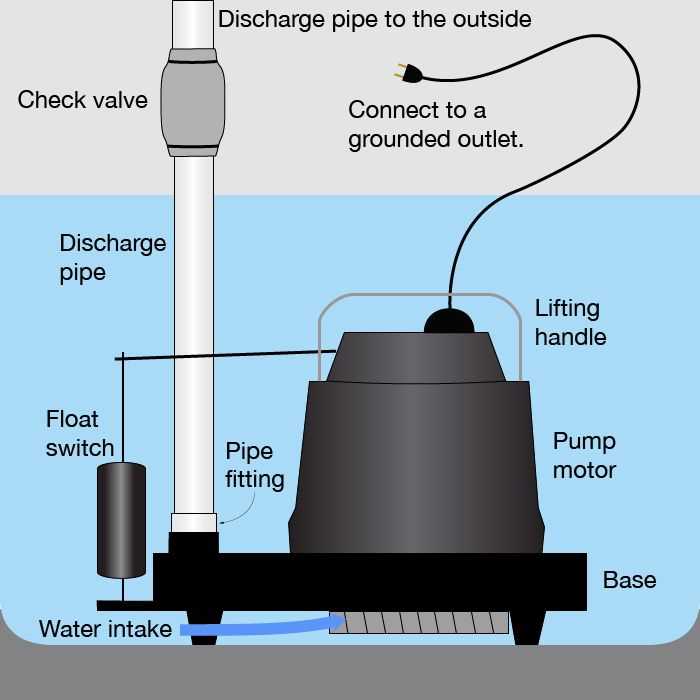

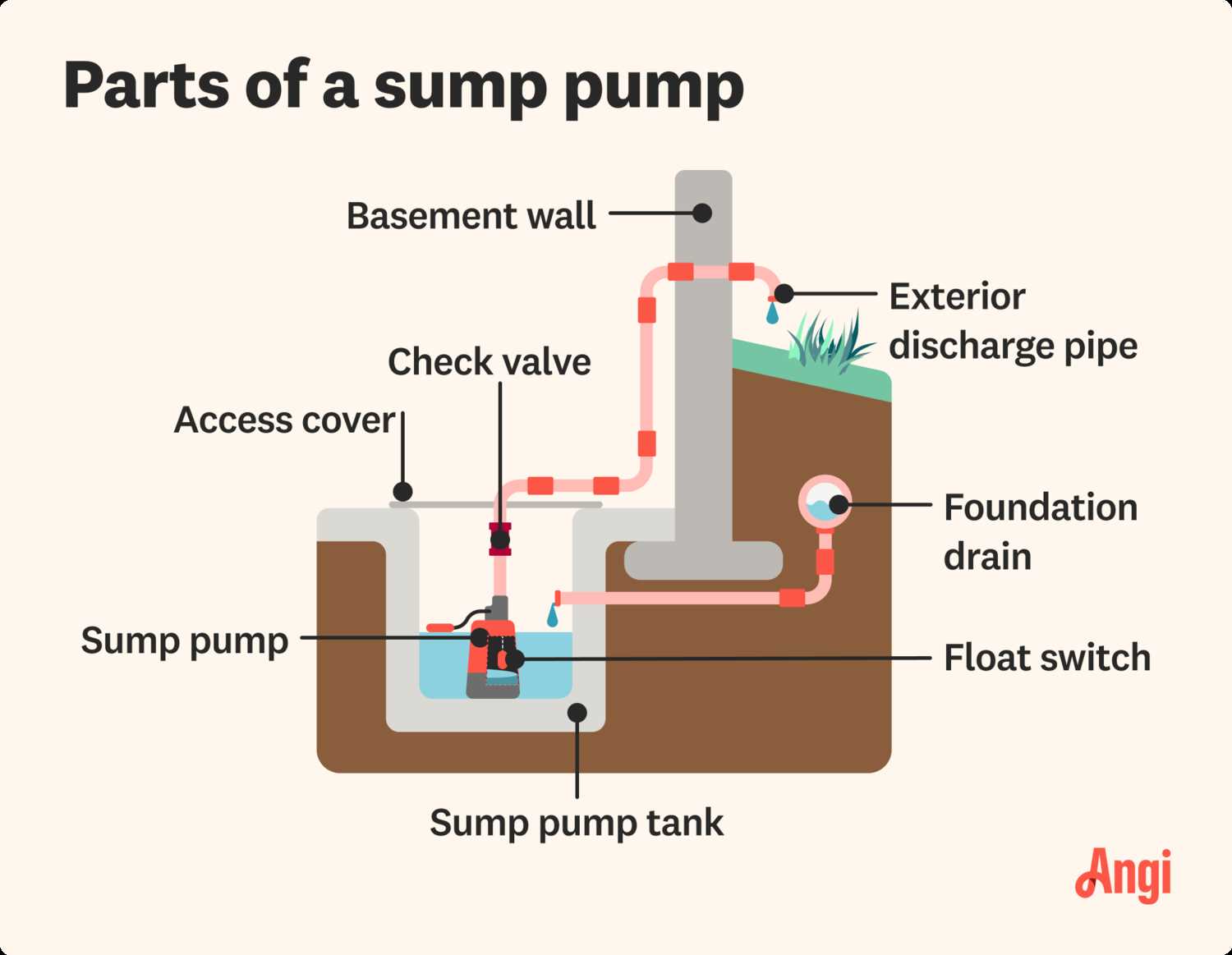

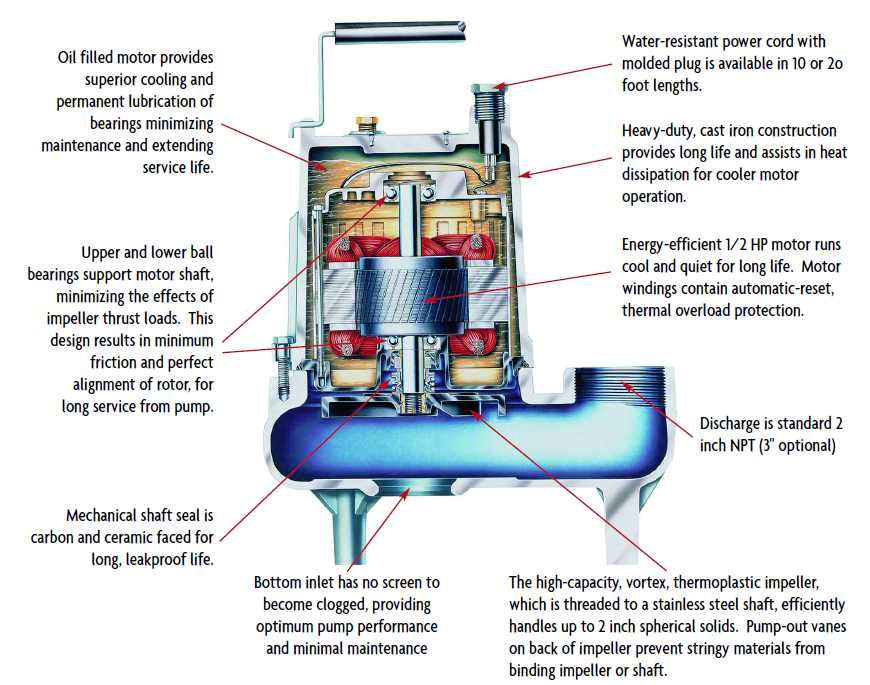

The core of any water management setup consists of a few main elements that work together to collect and expel water. The primary functional component is a motorized mechanism that drives the water through a discharge pipe, effectively clearing the area of excess moisture. This system is activated when water levels reach a certain threshold, ensuring timely operation.

Supporting Mechanisms

In addition to the main functional unit, supporting components such as the float switch, check valve, and discharge line contribute to the smooth operation of the entire system. The float switch activates the mechanism when the water level rises, while the check valve ensures water doesn’t flow back into the system. Together, these parts enhance efficiency and longevity, ensuring that the system continues to perform as expected.

How a Flood Control System Functions

At its core, this system is designed to remove excess water from areas where flooding can cause damage. When water levels rise, the system activates to efficiently divert moisture away, ensuring the space remains dry and protected. The process involves a sequence of actions triggered by specific conditions, working seamlessly to maintain control over water levels.

The mechanism typically relies on a sensor or float that detects when water reaches a certain height. Once activated, the motorized system starts to move water through the connected discharge pipe, directing it away from the area. The process continues until the water level drops to a safe point, at which time the system deactivates, ready for the next cycle.

Maintaining Your Flood Control System

Regular upkeep is essential to ensure that your water removal system continues to function effectively. Over time, debris, wear, and tear can affect performance, leading to possible failures during critical moments. Routine maintenance helps identify potential issues early, preventing costly repairs and extending the life of the system.

Begin by regularly checking for any blockages or debris in the intake area, as this can impede water flow. Ensuring the discharge pipe is clear and free of obstructions will prevent backflow and maintain efficient operation. Additionally, testing the float switch and motor periodically ensures that the activation system works correctly when needed.