Every mechanical system relies on precise arrangements of components to function correctly. A clear visual representation of these parts is essential for troubleshooting, assembly, and repair. Such visuals enable users to pinpoint connections, identify necessary replacements, and understand how the system operates as a whole.

These visual guides serve as invaluable tools for those unfamiliar with complex systems, offering a step-by-step look at the layout and interrelation of essential elements. By using these diagrams, technicians and engineers can streamline maintenance processes, reducing errors and improving efficiency.

Effective use of these illustrations requires careful attention to detail. Understanding each piece’s role within the larger structure is critical, as it ensures proper handling and prevents costly mistakes during repairs or reassembly.

Understanding the Assembly Breakdown

To effectively maintain or repair any complex system, it is crucial to have a clear understanding of how its components are arranged and interact with each other. A detailed visual representation allows for a more intuitive grasp of the overall structure, making it easier to identify specific elements and their function within the assembly.

Key Elements to Identify

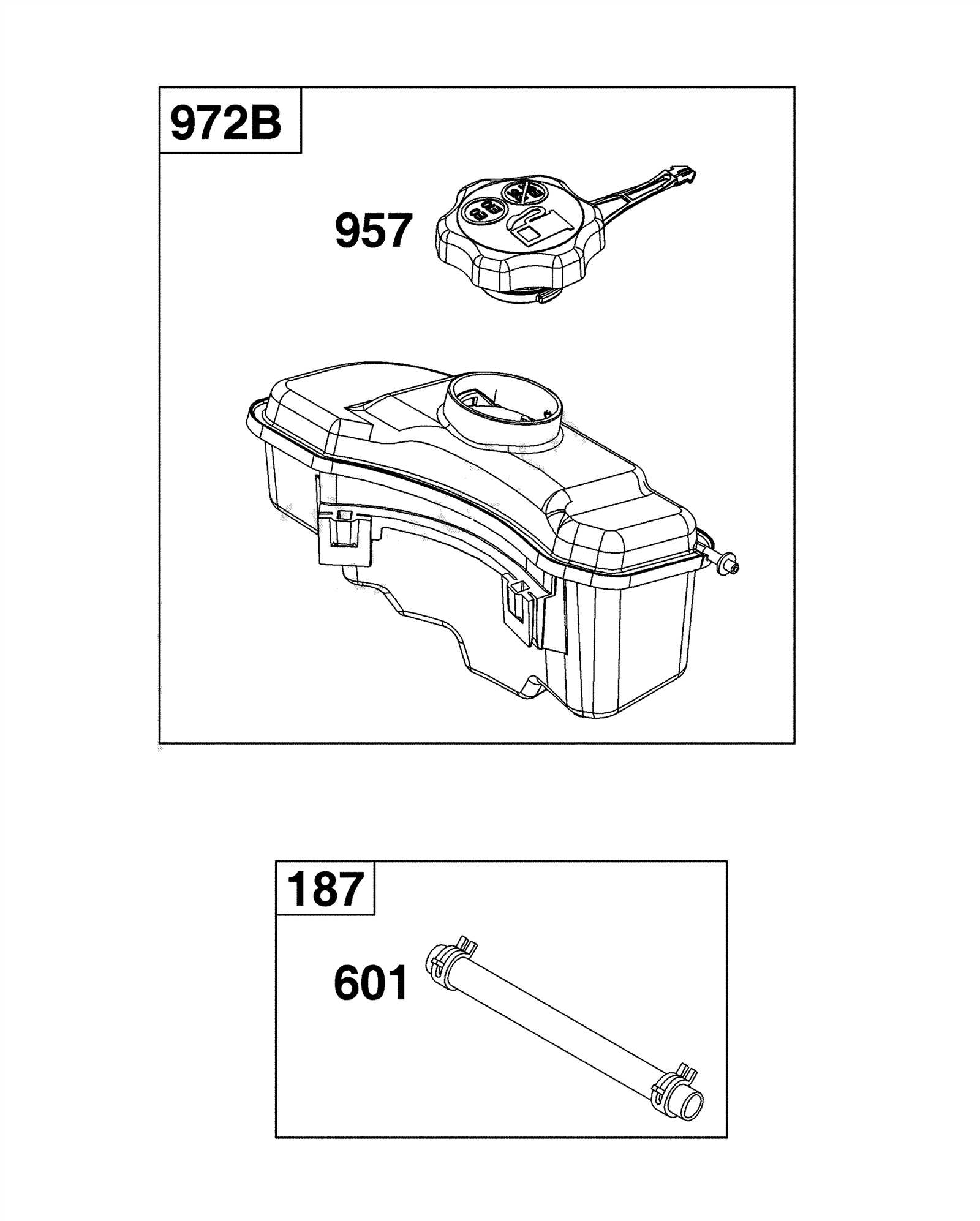

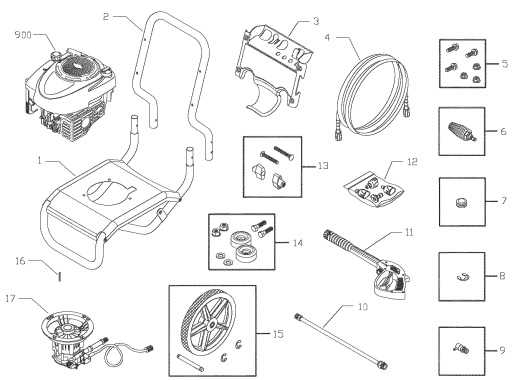

Each visual guide includes various labeled sections that illustrate how components fit together. Recognizing these labels helps technicians quickly pinpoint the parts that need attention or replacement. Being familiar with each element’s role can also aid in more accurate diagnostics and ensure that any issues are resolved efficiently.

How to Read the Visual Layout

It’s important to understand the conventions used in these visual aids. Symbols, numbers, and shapes all follow a specific logic that, when understood, simplifies troubleshooting and repair. By familiarizing yourself with this layout, you can avoid mistakes and handle the assembly with confidence.

How to Read the Assembly Layout Effectively

Interpreting a visual guide for any complex system requires attention to detail and understanding of key elements that define its structure. Knowing how to properly read these guides can significantly improve your efficiency in troubleshooting, assembling, or repairing components. By following a systematic approach, you can avoid confusion and ensure accuracy in your tasks.

- Familiarize Yourself with Symbols: Each visual guide uses specific symbols to represent different types of components. Understanding these symbols will help you quickly identify what you are looking at.

- Pay Attention to Numbering: Numbers often correspond to individual elements, so paying close attention to this numbering system allows you to track each piece’s position and function.

- Follow the Layout Flow: These guides typically have a flow that shows the assembly order or the relationship between components. Following this flow will help you understand how different parts interact.

By focusing on these basic principles, you can navigate through the illustration more effectively and reduce the risk of errors during repairs or installation.

Common Issues Identified in the Layout

When examining an assembly guide, it’s important to recognize common issues that may arise from misinterpretation or errors in the design. Identifying these problems early on can save time and prevent unnecessary complications during maintenance or repair. A detailed analysis of the visual layout allows for the detection of discrepancies or malfunctions that may otherwise go unnoticed.

Misalignment of Components

One of the most frequent issues is the misalignment of individual elements within the overall structure. This can occur if the components are not assembled in the correct sequence or if there is a misunderstanding of how parts should fit together. Misalignment can cause operational failures, making it essential to carefully follow the guide to ensure proper placement.

Missing or Damaged Elements

Another common problem is the omission of specific components or the presence of damaged parts. If a section of the visual guide is unclear or incomplete, it can lead to missing elements that are crucial for functionality. Damaged pieces might also be overlooked, compromising the integrity of the system. Regularly checking for such issues is vital to maintaining the system’s reliability.