When dealing with any portable energy device, understanding its internal structure is essential for efficient use and maintenance. A clear grasp of how each component interacts ensures that users can troubleshoot, repair, and optimize performance effectively. This guide will help you navigate through the various elements of your device and understand their functions and placement within the system.

Familiarity with the internal structure of such equipment can significantly extend its lifespan and improve its reliability. By reviewing the assembly and layout, you can pinpoint any issues that may arise and address them quickly. Whether it’s routine maintenance or an unexpected malfunction, knowing the layout of your machine is key to solving any challenges.

In this section, we’ll break down the crucial components and their roles, so you can easily identify each piece and its contribution to the overall functionality. With this knowledge, managing and maintaining your device becomes much more straightforward.

Understanding the Components of a Power System

Every energy device consists of several key elements that work together to provide a reliable power source. To fully comprehend how these systems function, it is important to become familiar with each component’s role and how they interact. Knowing the purpose and placement of each part helps in better maintaining and troubleshooting the system, ensuring optimal performance.

Core Elements for Efficient Function

The main elements of a portable energy system include the core power-producing components, the control mechanisms, and the output systems. These are all essential for converting fuel into usable energy and directing it to the necessary channels. Understanding how each piece contributes to the overall operation can help identify potential areas of improvement or failure.

Maintenance and Troubleshooting

Proper maintenance of each component is vital to keeping the equipment running smoothly. Regular checks on the fuel delivery system, electrical connections, and output mechanisms will prevent long-term damage. Identifying issues early through knowledge of the internal structure enables users to resolve problems quickly and efficiently, keeping the equipment in good working condition for years to come.

How to Read the Device Layout

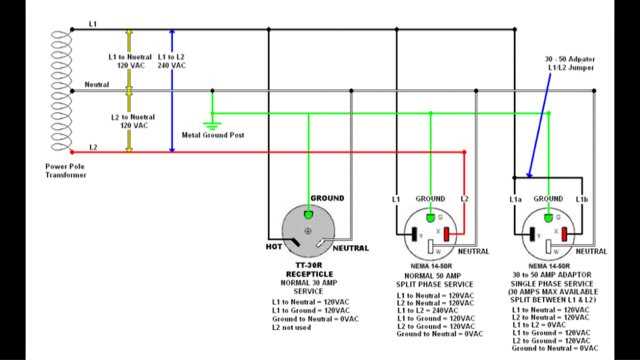

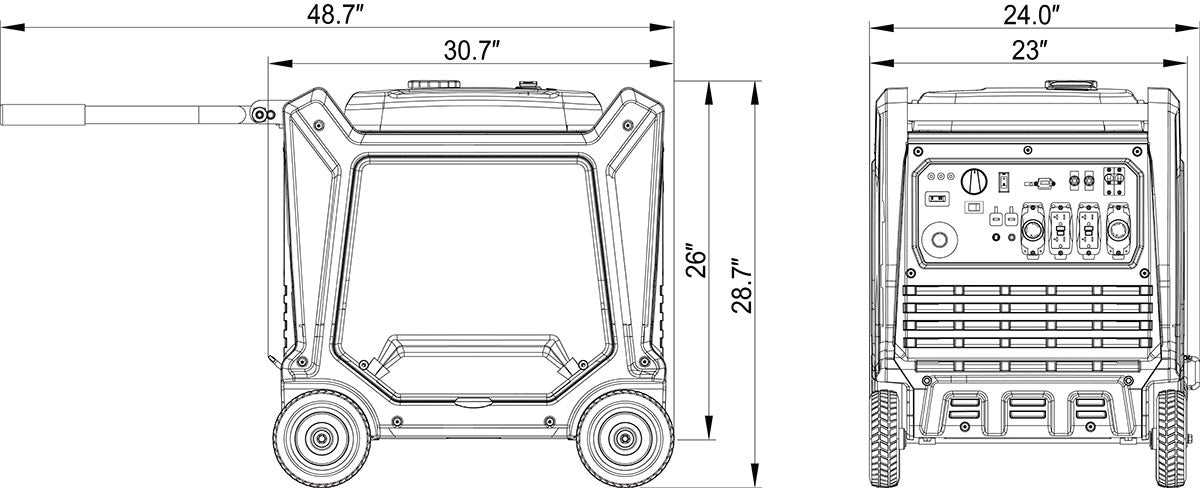

Understanding a layout blueprint is essential when working with any complex system. These blueprints provide a visual representation of the components, their connections, and how they function together to produce power. Being able to read and interpret such diagrams effectively allows users to locate specific elements, identify potential issues, and understand how each part contributes to the overall system.

Interpreting Symbols and Labels

Each diagram uses a set of standard symbols to represent different parts and functions. These symbols are crucial for identifying each component’s role within the system. Labels and annotations on the diagram further clarify the connections, indicating power flow, input/output points, and control interfaces. By carefully studying these elements, users can pinpoint exactly where adjustments or repairs need to be made.

Understanding Connections and Flow

The layout also highlights the connections between different parts, such as electrical links and fuel pathways. Recognizing the flow of energy throughout the system helps in troubleshooting and makes it easier to identify faults. By following these paths, users can ensure everything is properly connected and functioning as intended, reducing the risk of failures and improving overall performance.

Key Parts for Power System Maintenance and Repair

Regular upkeep and timely repairs are crucial for ensuring the longevity and efficiency of any energy-producing device. Identifying the most critical elements that require attention during maintenance helps prevent breakdowns and ensures smooth operation. Focusing on key components allows users to perform effective repairs and avoid costly malfunctions.

Fuel System – This is one of the primary systems that requires periodic inspection. Ensuring proper fuel delivery and cleanliness of filters can prevent clogs and improve performance. Routine checks on fuel lines and the fuel tank are necessary to maintain optimal operation.

Electrical Connections – The wiring and electrical circuits must be checked regularly to avoid issues with power delivery. Corrosion or loose connections can disrupt the flow of electricity, leading to inefficient performance. Cleaning terminals and tightening connections ensures steady operation.

Air Filter and Exhaust System – Keeping the air intake clean is essential for maintaining efficient combustion. A clogged filter can reduce airflow, causing the system to work harder and less efficiently. Likewise, checking the exhaust system for blockages ensures smooth operation and reduces wear on the engine.