When dealing with automatic gearboxes, it’s essential to understand the internal structure that ensures smooth operation. Knowing how the different elements interact can help diagnose issues and assist in maintenance or repair. Each part plays a specific role, and without a clear understanding, identifying problems or making necessary adjustments can become a challenge.

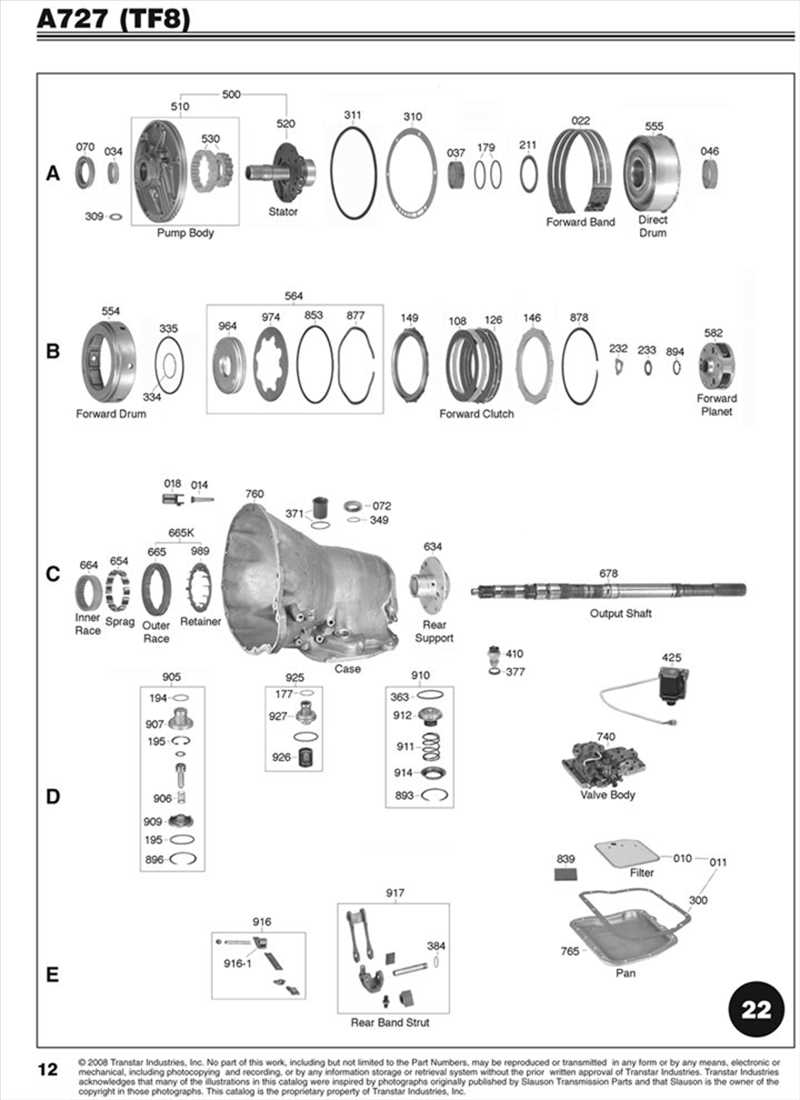

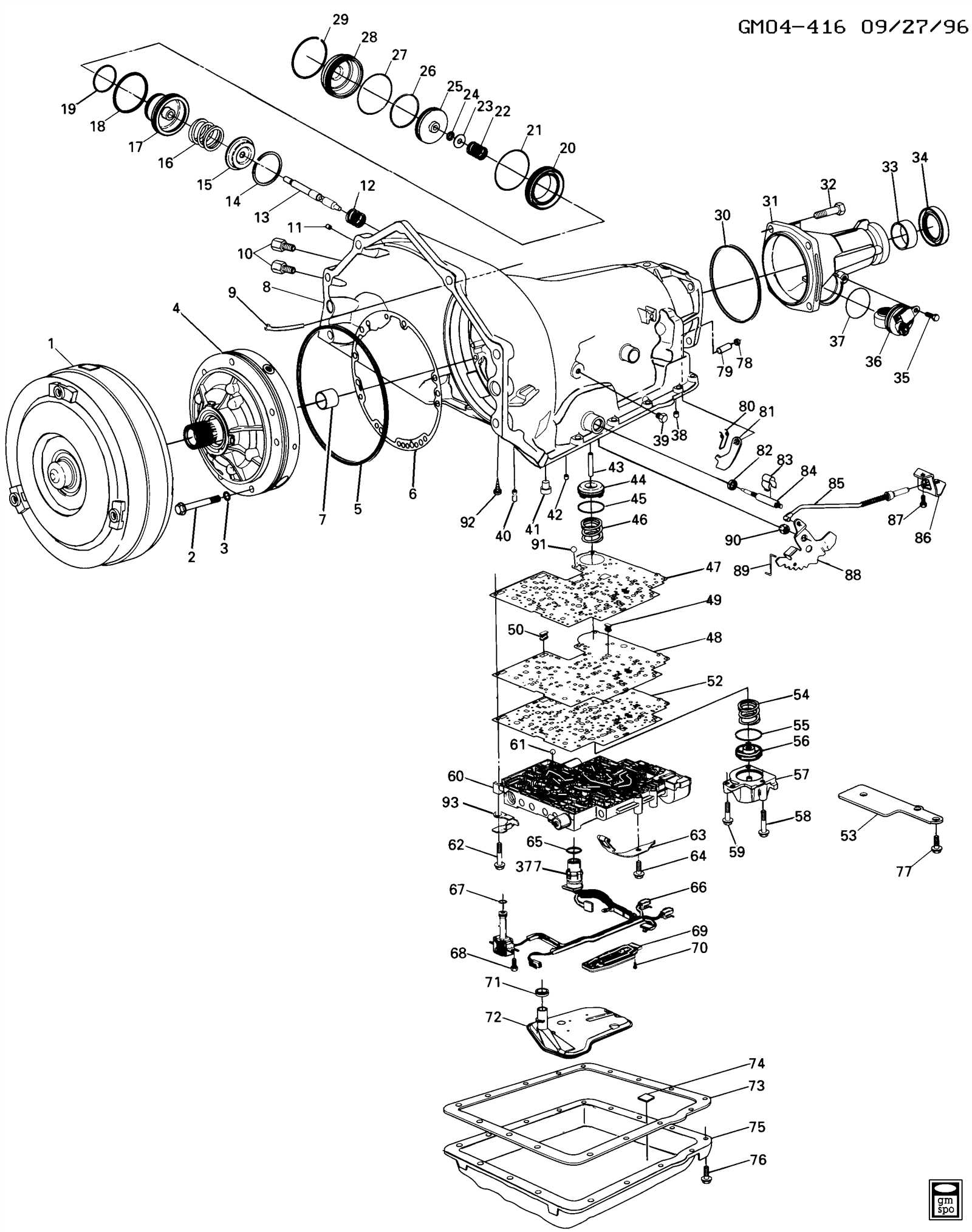

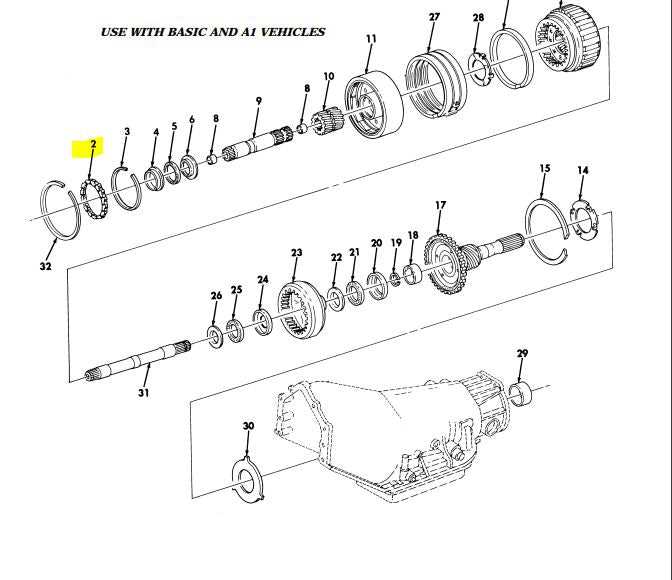

Visual representations of these internal systems can be invaluable tools for mechanics and enthusiasts alike. By breaking down the components and understanding their functions, you can gain insight into the transmission’s overall performance. This knowledge can also help prevent unnecessary replacements by identifying minor issues early on.

Having access to an accurate layout of the internal structure aids in achieving precision when working on or restoring a transmission. Whether you are a professional or a DIY mechanic, knowing what each piece does and how it fits together is crucial for effective repairs and maintenance.

Understanding the 4L60E Transmission Components

Every automatic transmission consists of a complex network of interconnected elements that work together to ensure the vehicle shifts smoothly between gears. Each component plays a vital role in the overall function, from controlling fluid flow to engaging different gear ratios. Familiarity with these individual parts is essential for diagnosing and addressing transmission issues effectively.

Main Elements of the Transmission System

The primary sections of the system include the valve body, clutch packs, and servo mechanism, all of which work in tandem to manage the movement of gears. The valve body acts as the brain, directing hydraulic fluid to various components based on driving conditions. The clutch packs enable gear changes, while the servo adjusts the transmission’s response to shifting demands.

Key Functional Components

Another crucial part is the pump, which circulates fluid throughout the transmission, providing the necessary pressure to ensure all mechanisms function correctly. The input and output shafts connect to the engine and drive the wheels, respectively, making them indispensable for power transfer. Understanding these elements allows for more accurate troubleshooting and repair work when issues arise.

How to Read a 4L60E Parts Diagram

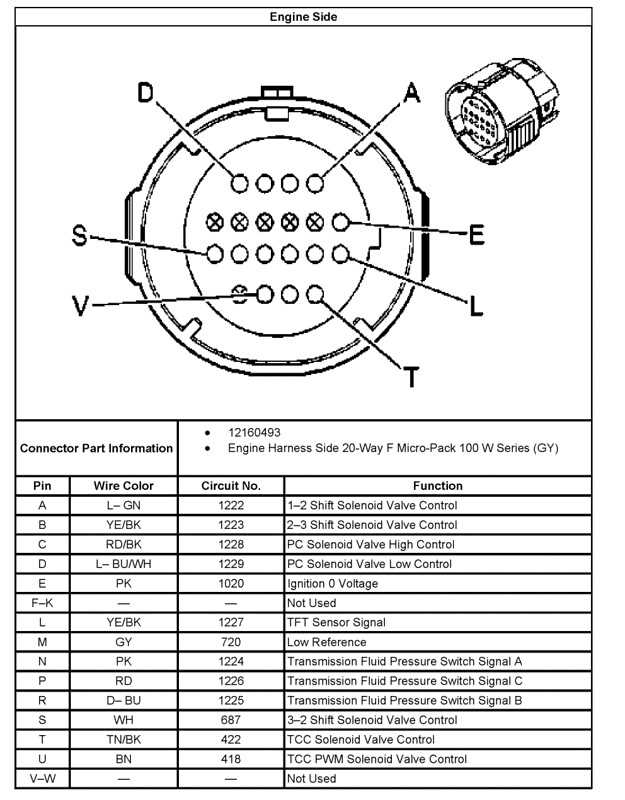

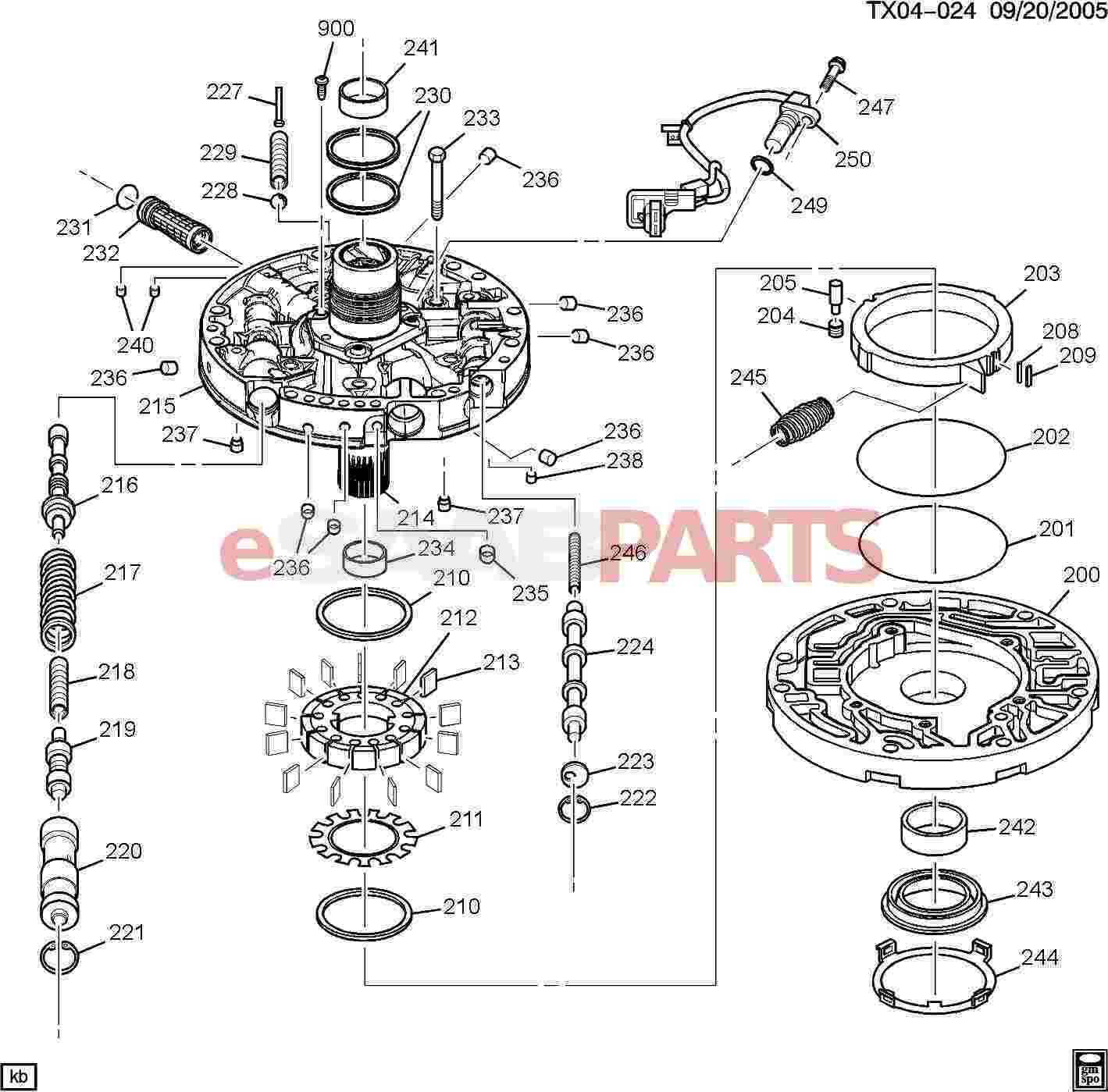

Understanding visual representations of an automatic transmission system is key to effectively diagnosing and repairing issues. These illustrations typically show the arrangement of different components and how they interact within the system. By learning how to interpret these schematics, you can gain a deeper understanding of the transmission’s structure and function.

Begin by familiarizing yourself with the different symbols and labels used in the visual guide. Each part is often depicted with a specific shape or code, which corresponds to its function. Pay attention to the arrows and lines, which usually represent the flow of fluid or the movement of internal mechanisms. Understanding these connections helps to visualize how energy is transferred and which components are involved in each shift.

Once you identify the key components, focus on their placement relative to one another. The layout typically shows how parts fit together, allowing you to troubleshoot issues more efficiently. This knowledge is invaluable when working on repairs, as it guides you in isolating faulty components and determining what needs replacement or adjustment.

Common Issues and Solutions for 4L60E Parts

Like any mechanical system, automatic transmissions can experience wear and tear over time. Certain components may degrade, leading to performance issues or even complete failure. Identifying these issues early can save both time and money by allowing for timely repairs. Understanding common problems and their solutions is crucial for keeping the transmission running smoothly.

Common Problems with Internal Components

A frequent issue is fluid leakage, which can occur from seals or gaskets that have worn out. This leads to a loss of hydraulic pressure, causing poor shifting or slipping. Replacing the damaged seals is typically the solution, along with checking fluid levels to ensure the transmission operates at the proper pressure. Another common problem is overheating, which often results from a clogged cooler or insufficient fluid levels. Regular maintenance and cleaning of the cooler system can prevent this from becoming a serious issue.

Shifting and Response Issues

If the transmission hesitates or fails to shift properly, it might be due to problems with the valve body or shift solenoids. These parts regulate fluid flow and gear selection. In such cases, cleaning or replacing the faulty solenoids usually resolves the issue. Additionally, worn-out clutch packs can cause delayed or harsh shifts. Replacing the clutch packs and adjusting the pressure can restore smooth shifting and prevent further damage to the system.