Every mechanical system requires a clear visual representation of its key elements. This allows for efficient operation, maintenance, and troubleshooting. A well-organized overview is crucial for users to identify each part and understand how they interact with each other. Whether you’re assembling, repairing, or simply maintaining the system, having a reference that clearly outlines these components can save both time and effort.

Interpreting the Visual Reference

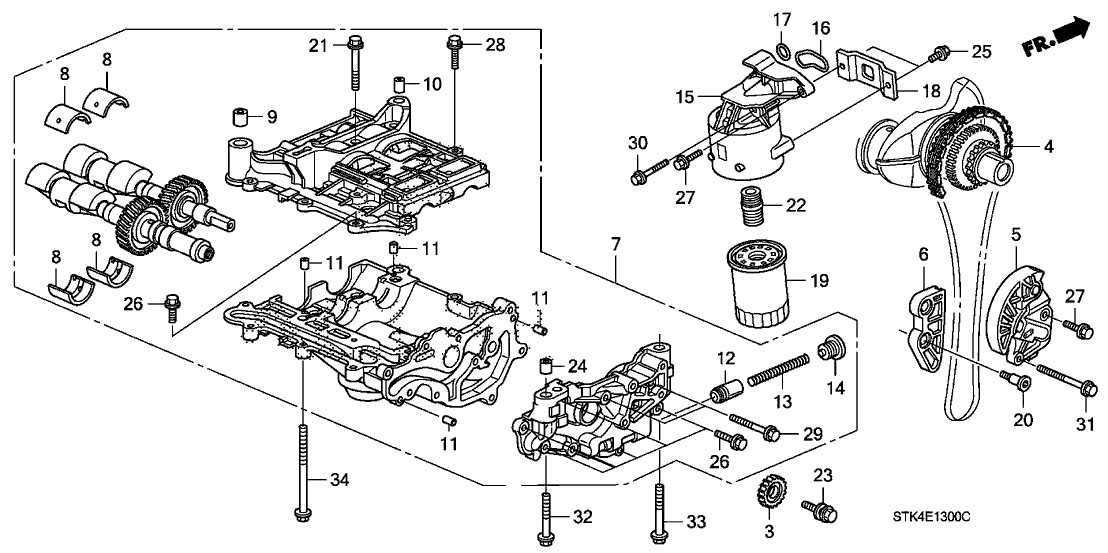

To fully grasp the workings of the system, it’s essential to decode the visual chart that illustrates the key components. This visual guide helps to identify each part’s specific role and placement. It is typically divided into sections that highlight various parts of the machinery, helping you recognize and understand the function of each one. The clarity of this representation can significantly streamline your work, ensuring every part is easily identifiable.

Common Issues to Look Out For

While using a system, certain components may malfunction or wear down over time. A quick inspection of the visual guide can help detect any inconsistencies or failures. By understanding the design, users can pinpoint where the issue might lie, whether it is a misalignment, wear, or damage to specific parts. This proactive approach helps prevent larger failures that may arise from ignoring smaller faults.

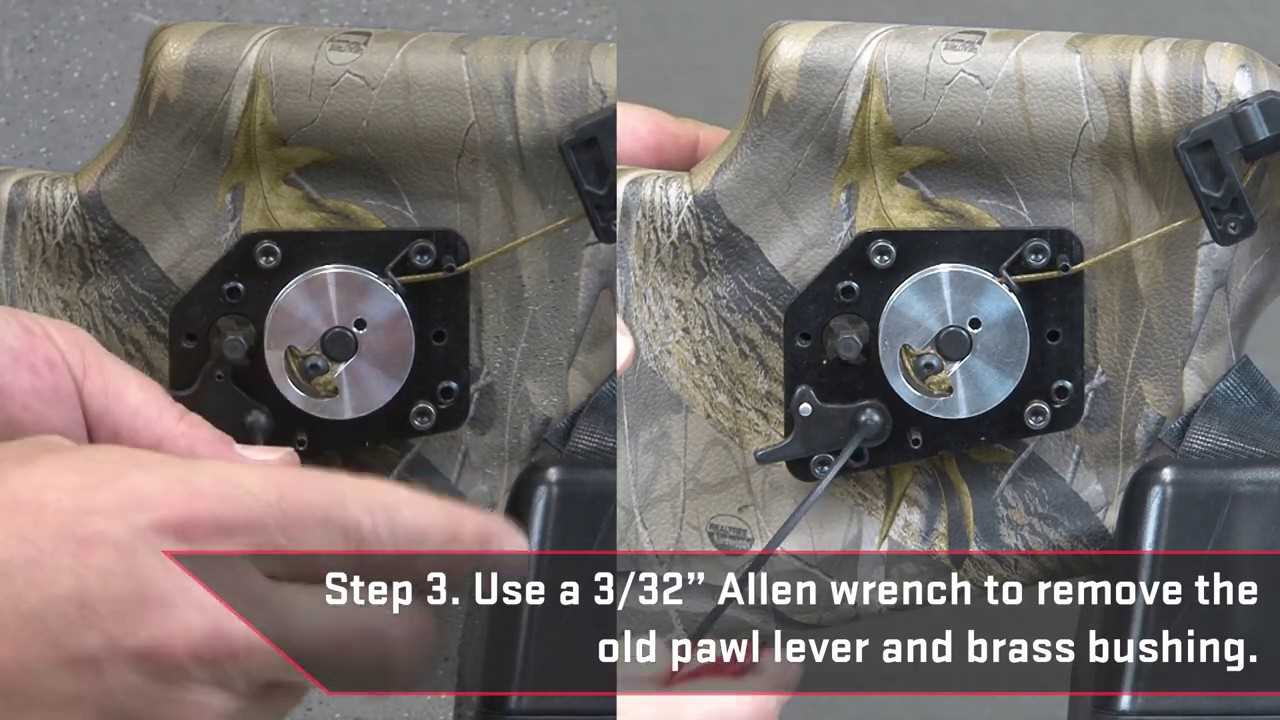

Proper Maintenance Guidelines

Routine maintenance is essential to prolong the lifespan of any system. Regular checks using the visual guide can highlight areas that need lubrication, tightening, or replacement. By following the maintenance recommendations specific to each part, the overall functionality and longevity of the equipment can be ensured. Understanding the exact placement and condition of every element allows for more precise interventions.

Troubleshooting with a System Overview

If something goes wrong with the system, having a comprehensive visual guide is indispensable. This tool enables you to systematically troubleshoot by cross-referencing potential issues with specific parts. By examining the components in a logical sequence, you can narrow down the cause of the malfunction, ensuring a quicker and more accurate resolution.

Understanding the System Components and Their Functions

Every mechanical system is made up of various elements, each contributing to its overall function. Understanding how these elements work together and how they are represented is essential for efficient operation, maintenance, and repair. A clear visual representation of the system’s structure can provide significant insight into the layout and connections of these parts, aiding in both basic understanding and troubleshooting.

Interpreting this visual guide involves recognizing the unique roles of each component and how they interact with others. By following the outlined structure, users can learn to identify specific pieces and their functions in a system. A well-structured layout simplifies the process of understanding complex machinery and makes it easier to identify what needs attention during maintenance or troubleshooting.

Common Problems in Mechanical Systems

With time and usage, certain elements of a system may begin to fail or degrade. Problems such as wear and tear, misalignment, or incorrect installation are common issues that can arise. A well-illustrated guide can help pinpoint these issues by providing clear details about each element’s placement and condition. By recognizing these problems early, it is possible to avoid more severe damage and maintain system integrity.

Routine Maintenance and Care

To ensure a system operates smoothly over its lifetime, regular maintenance is crucial. Using a reference to check the condition of each component helps in identifying parts that require lubrication, adjustment, or replacement. By following proper care guidelines, users can extend the life of the equipment and prevent unexpected breakdowns. Knowledge of the system’s layout ensures that maintenance is performed efficiently and correctly.

Effective Troubleshooting Techniques

When issues arise, troubleshooting becomes a crucial step in restoring functionality. A clear visual overview allows users to methodically inspect each part, identify faults, and determine the root cause of the problem. This structured approach aids in quicker and more accurate solutions, ensuring minimal downtime and maximum efficiency in resolving issues.