Efficient operation of a heating, ventilation, and cooling system relies heavily on the proper functioning of its internal components. Each element plays a crucial role in ensuring that the entire system operates smoothly. Understanding how these elements work together can help in troubleshooting and maintaining the equipment for optimal performance.

Familiarizing yourself with the structure of your system makes it easier to identify potential issues when they arise. Knowing the location and function of each crucial component can save both time and money during repairs. This knowledge can also prevent unnecessary replacements and ensure longevity for the system.

By examining the components carefully, you’ll be able to determine what needs attention and take steps toward fixing minor problems before they escalate into more costly repairs. Recognizing the value of each individual part can provide greater insight into maintaining a well-functioning system throughout its lifespan.

Understanding the Components of an Air Handler

Each system designed for heating, cooling, and ventilation contains several essential elements that work together to maintain indoor comfort. Recognizing these components and their functions is key to ensuring the system runs efficiently. Every part plays a distinct role, and understanding their interaction helps in identifying potential issues early on.

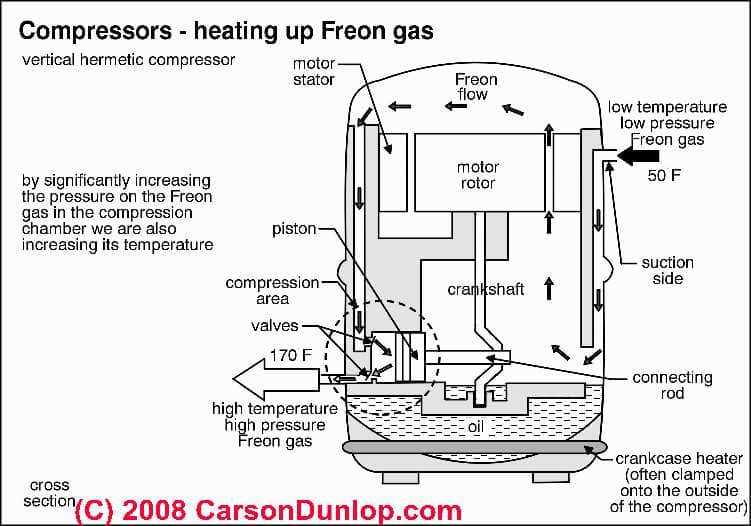

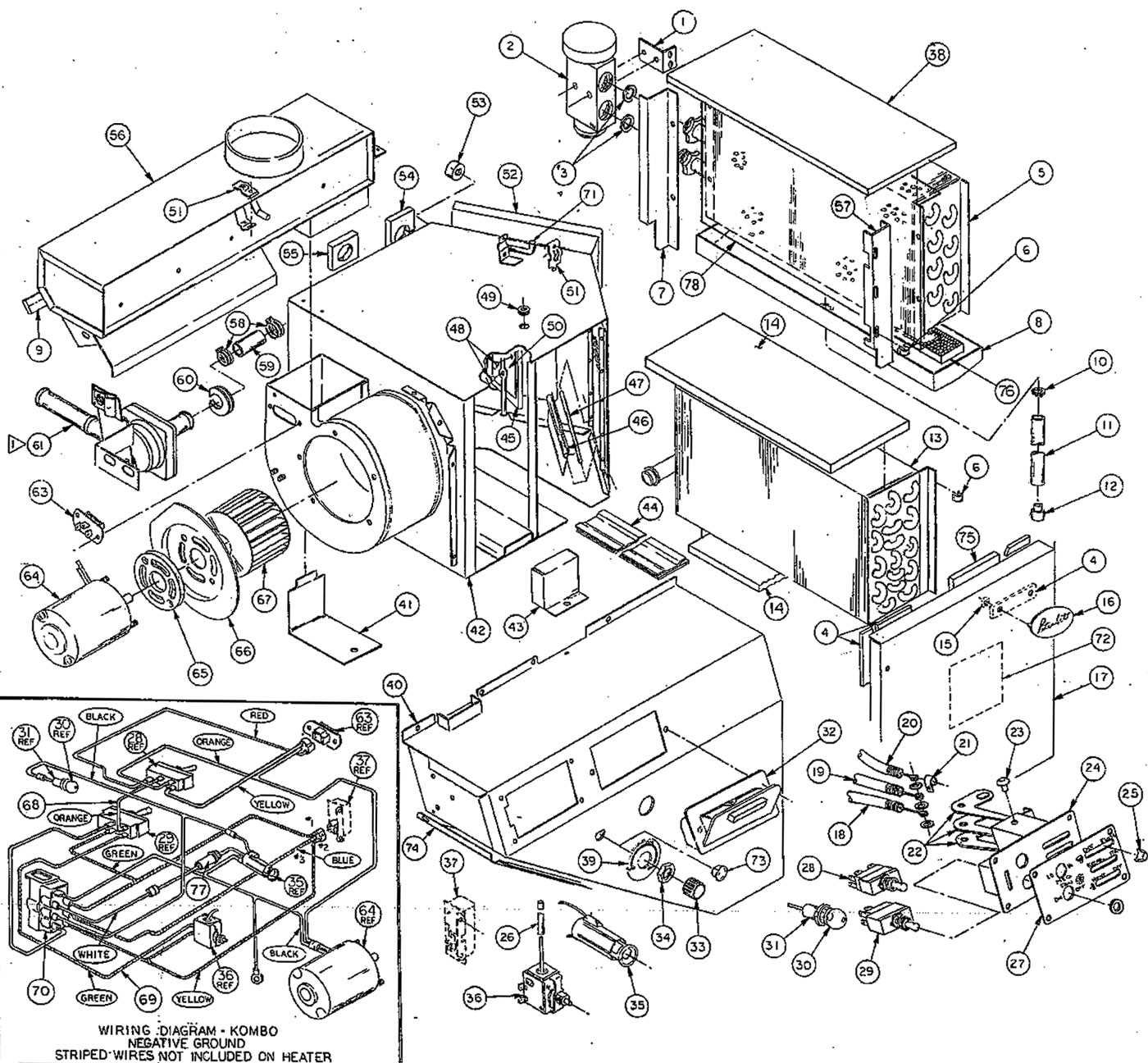

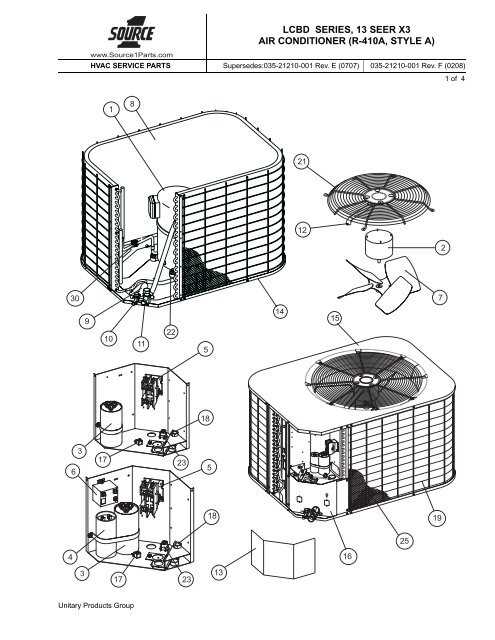

Core Elements of the System

The core components of the system include a series of conduits, motors, and filters that facilitate air movement and temperature regulation. Each part contributes to airflow, conditioning, and filtering of air as it circulates throughout the space. Proper maintenance of these elements ensures a consistent and effective system performance.

Importance of Regular Maintenance

Routine checks and servicing of these integral components can prevent costly breakdowns. Regular cleaning of filters, inspection of motors, and checking the efficiency of ventilation pathways are simple tasks that can dramatically improve system longevity. Keeping each element in optimal condition reduces the chances of unexpected repairs and maintains energy efficiency.

How to Identify Air Handler Parts

Recognizing the key components within your system is crucial for effective troubleshooting and maintenance. By familiarizing yourself with the individual elements, you can identify issues early and avoid unnecessary repairs. Each part contributes to the overall functionality, and understanding their specific role is essential for proper upkeep.

Recognizing Major Elements

The first step in identifying the key components is to understand the primary functions they serve. Some parts are responsible for air circulation, while others control temperature or filtration. The most common components include blowers, motors, filters, and coils, each with a distinct location and appearance in the system. Once you know what each component looks like, it becomes easier to spot them in a complex setup.

Inspecting the Components for Issues

Once identified, it’s important to inspect each element regularly for signs of wear or malfunction. Visual checks can reveal damage or dirt buildup that might affect performance. Additionally, testing the function of each component, such as the airflow or motor sound, helps to determine whether everything is operating smoothly. Early detection of any irregularities ensures timely action and avoids costly repairs later.

Common Issues with Air Handler Components

Systems designed for ventilation, heating, and cooling can experience a variety of issues with their internal components over time. Regular use, wear and tear, and poor maintenance can lead to malfunctions that affect efficiency. Understanding common problems with these elements can help you identify and address them before they become costly repairs.

Clogged Filters and Poor Airflow

One of the most frequent issues is the buildup of debris in filters. When filters become clogged, airflow is restricted, leading to reduced system efficiency. This can cause increased energy consumption and an inability to properly regulate temperature. Regularly changing or cleaning filters can prevent this issue and maintain optimal performance.

Worn-out Motors and Reduced Performance

Another common problem involves the motors that drive the system’s components. Over time, motors can become worn or damaged, leading to reduced performance or complete failure. Regular inspections and lubrication can extend the life of the motor, but if problems persist, replacement may be necessary to restore full functionality.