When it comes to maintaining your outdoor equipment, having a clear view of how the different parts work together is essential. Whether you’re troubleshooting a specific issue or performing routine maintenance, knowing the layout of your machine can save time and effort. Each component plays a vital role in the overall functionality, and understanding their relationships can help ensure smooth operation.

By exploring the visual representation of your snow blower’s internal system, you gain insight into where certain pieces fit and how they function. This detailed map can assist in identifying which parts need attention, making repairs simpler, and reducing the chances of overlooking important elements. Proper knowledge empowers you to make informed decisions about when to replace or fix specific components.

From the most common problems to routine upkeep, familiarizing yourself with this guide will improve your experience and help extend the life of your equipment. The clearer your understanding of the layout, the more effective your maintenance efforts will be, ensuring your machine performs at its best when you need it the most.

Understanding Snow Blower Components

Each snow blower consists of multiple essential components that work together to ensure its efficient operation. These elements, ranging from the engine to the auger assembly, must be carefully maintained to ensure the machine performs optimally. A clear understanding of how these pieces interconnect and function is crucial for troubleshooting issues and performing timely repairs.

The internal workings of the machine are made up of various mechanisms, each designed to perform a specific task, such as propulsion, snow collection, or discharge. When problems arise, recognizing which part is causing the issue allows for quicker diagnosis and reduces the risk of unnecessary replacements. Understanding the layout also enables you to identify potential weaknesses or wear points that need attention.

When it comes to replacing a broken or worn-out element, knowing the exact function of each component ensures you select the correct replacement. The overall design is optimized for durability, but even the most well-engineered systems require maintenance. Familiarity with your equipment’s structure can also help with regular checks, keeping your snow blower in top condition throughout its lifespan.

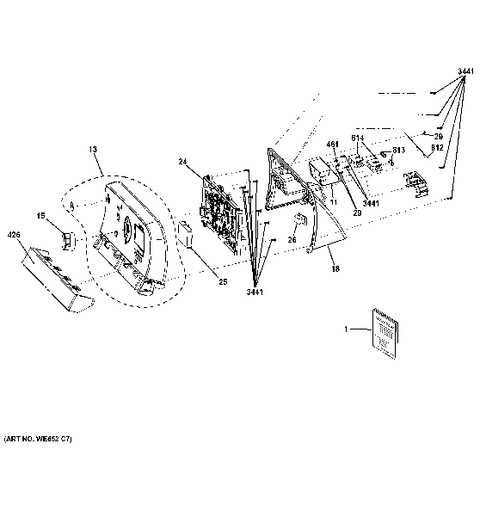

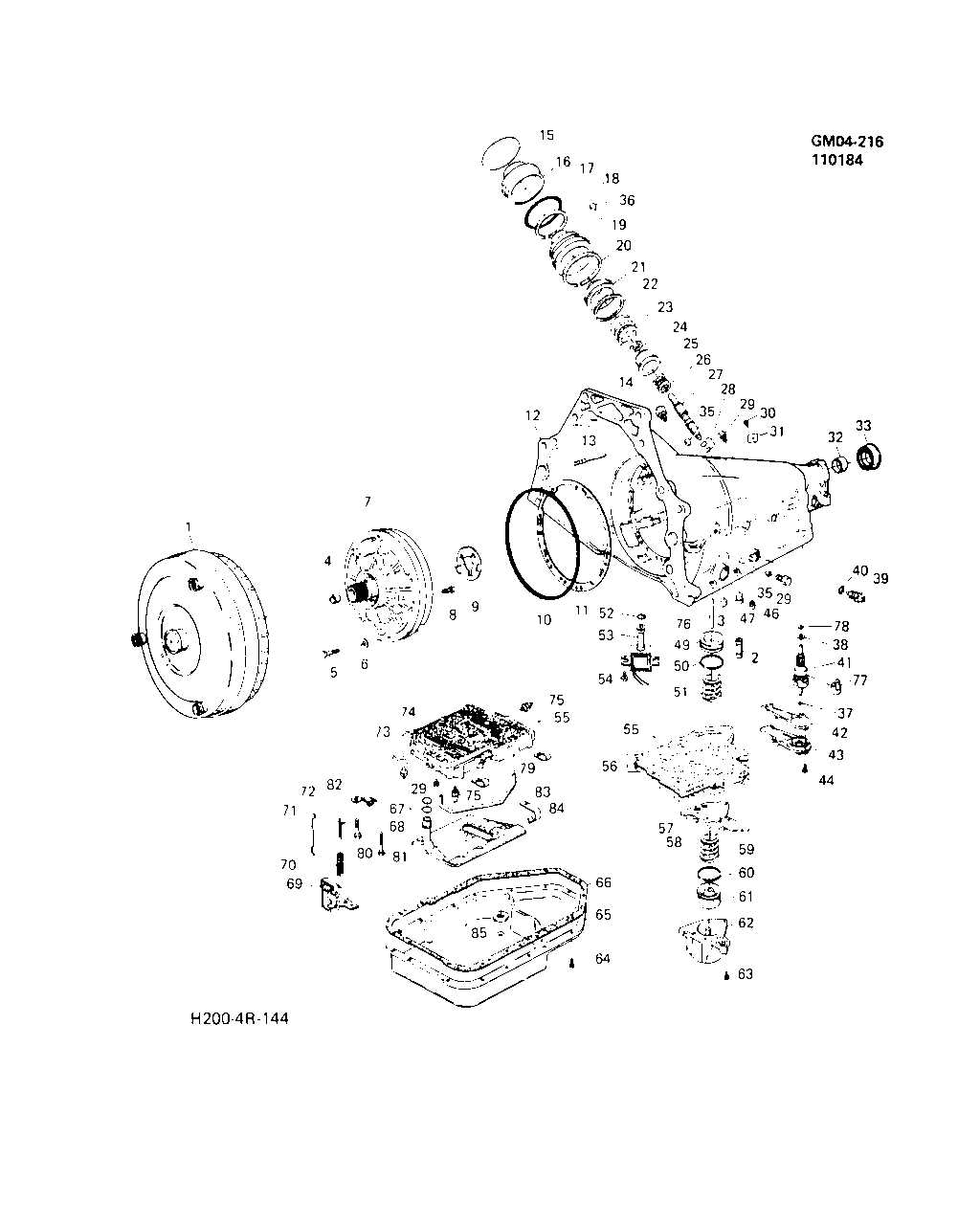

How to Read the Snow Blower Diagram

Understanding how to interpret a machine’s schematic is essential for efficient maintenance and repair. These visual guides provide a clear representation of the equipment’s internal structure, showing how each element fits into the overall system. Knowing how to read this chart can help identify components that need attention and make the process of troubleshooting far easier.

Typically, the schematic will present the parts in a detailed, labeled format. Each section is usually numbered or color-coded, allowing you to quickly locate the corresponding components in the real machine. Pay close attention to the key, which often provides explanations of symbols and terms used in the diagram, helping you avoid confusion.

Once you familiarize yourself with the layout and symbols, using the diagram to guide your maintenance becomes second nature. Whether you’re looking to replace a specific item or ensure all pieces are in working order, these visual aids offer a straightforward method for inspecting your equipment. With practice, you will be able to make more informed decisions regarding repairs and replacements.

Common Replacement Components for Snow Blowers

Over time, certain components of your snow clearing machine are more likely to wear out due to constant use and exposure to harsh weather conditions. Regular inspection and timely replacement of these elements are essential for ensuring that the equipment continues to operate effectively. Some components are more prone to damage than others and may need attention more frequently.

One of the most common items that require replacement is the auger assembly. This part is responsible for collecting snow and directing it toward the chute, and it can become worn or damaged after extended use. Another critical component is the drive belt, which transmits power from the engine to the wheels. If it wears out or snaps, it can cause a significant drop in performance.

Other commonly replaced items include the spark plug, which plays a vital role in engine ignition, and the chute control cables, which can stretch or fray with continued operation. Ensuring that you replace these parts when necessary will help avoid more serious issues down the line, keeping your machine in optimal working condition.