When it comes to maintaining and repairing machinery, understanding its internal structure is crucial. A clear visual representation can save time and effort, enabling quicker identification of issues and the proper parts for replacement. By familiarizing yourself with this layout, you gain the confidence needed to perform repairs with accuracy.

Whether you’re working on a lawnmower, tractor, or other outdoor equipment, having a detailed guide allows you to pinpoint the exact components. Proper knowledge of these structures ensures you can address problems effectively, leading to smoother performance and longer-lasting machinery.

By following a well-organized chart, you can easily locate necessary components and follow the correct procedure for repair or replacement. This organized approach helps prevent errors and ensures that each repair step is clear and efficient, making maintenance more manageable.

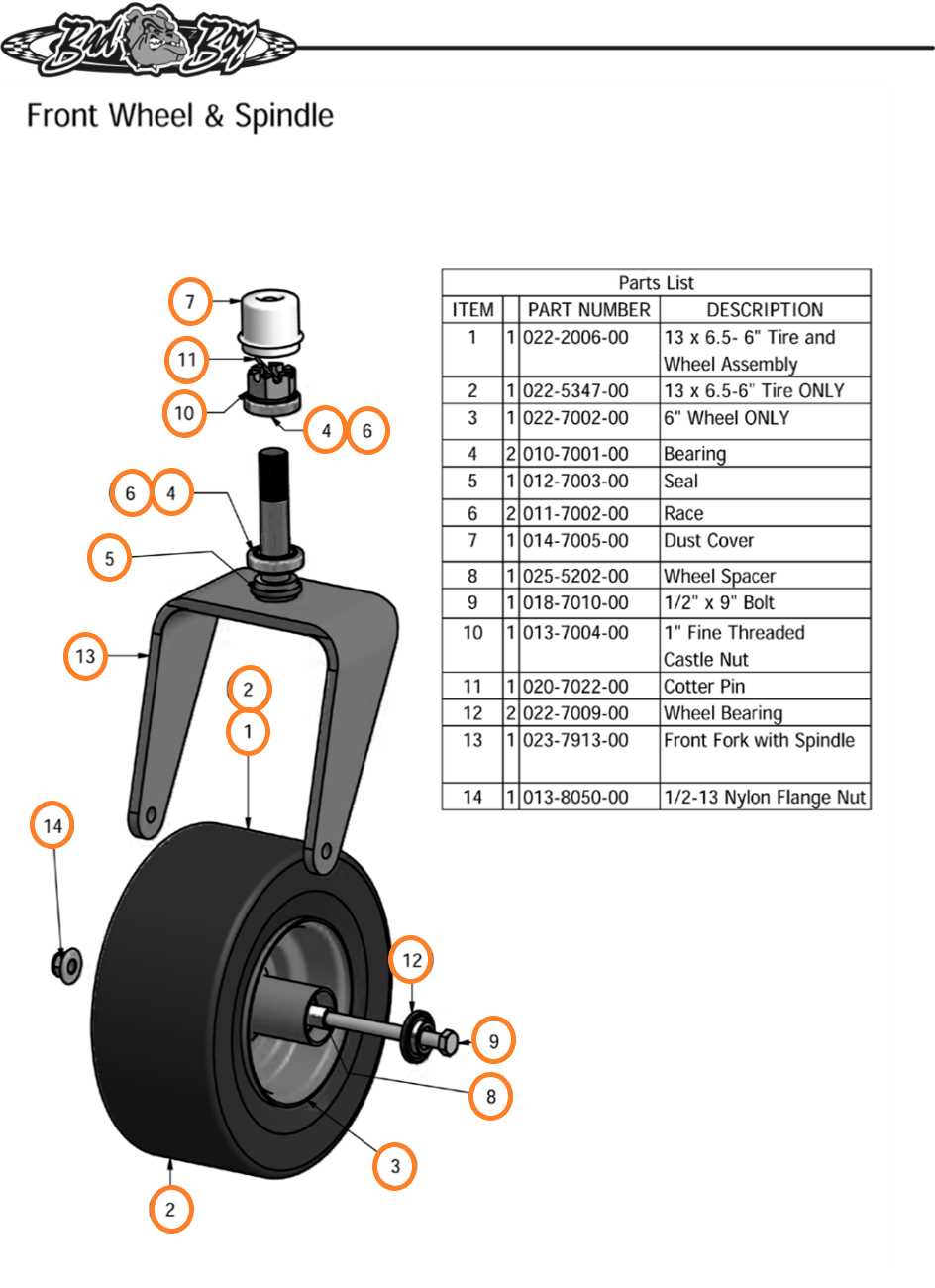

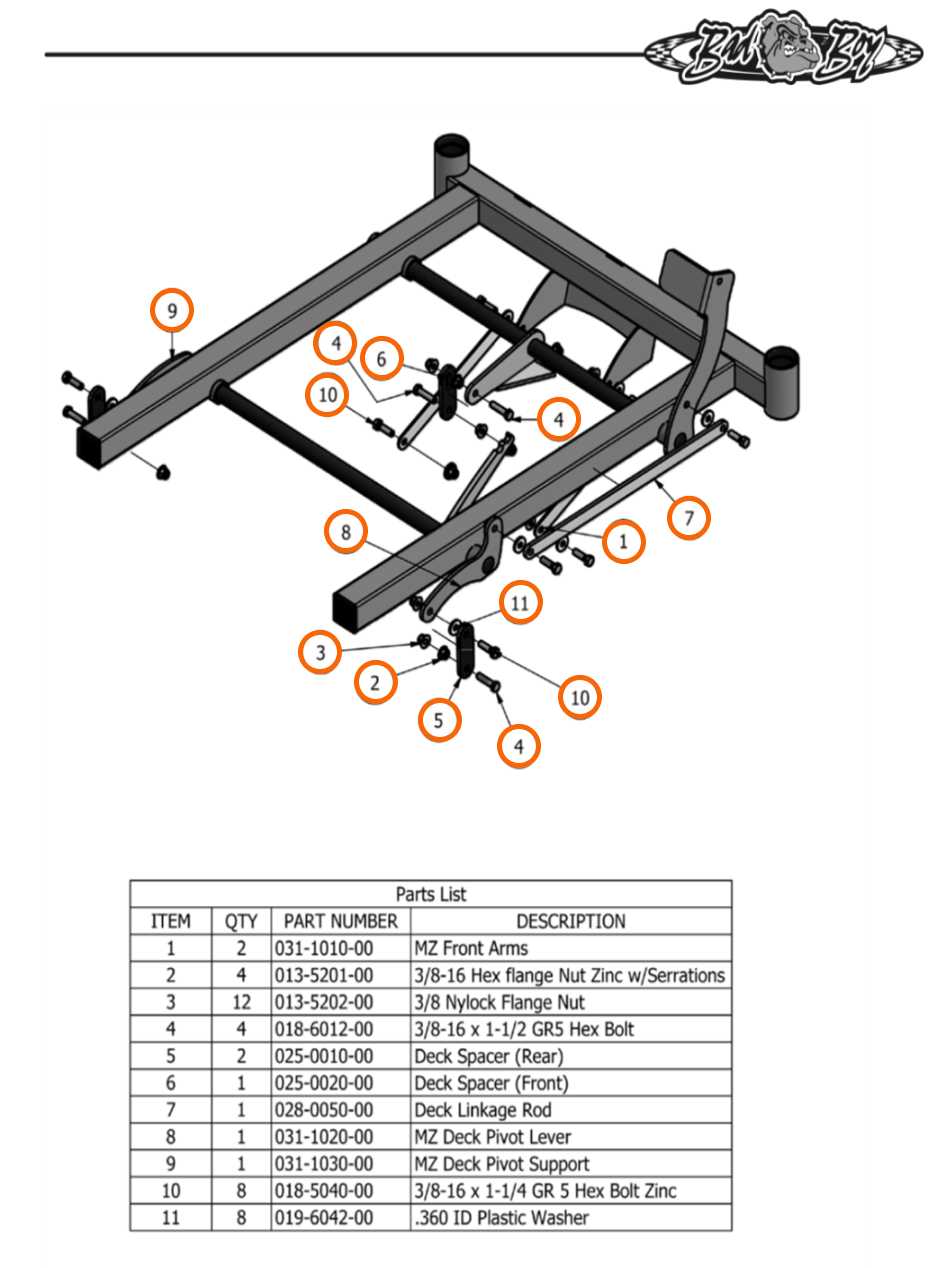

Understanding the Bad Boy Parts Diagram

Having a clear visual representation of the internal components of your equipment is essential for effective maintenance and repairs. By organizing the elements in an easy-to-understand format, it allows users to quickly identify the various sections and understand how they interact with each other. This knowledge can simplify troubleshooting and guide you to the right solution with confidence.

Such a layout typically divides the machine into specific areas, highlighting the most important components that require regular attention or replacement. Understanding these sections helps you focus on the necessary parts, ensuring you don’t waste time on non-essential elements. It also provides a clear map for anyone unfamiliar with the machinery, making maintenance more approachable and efficient.

Once familiar with the structure, users can recognize wear and tear or potential issues much sooner. This early detection prevents bigger problems, helping to prolong the life of the equipment and avoid costly repairs. Overall, this organized breakdown is key to keeping your machine in top condition, ensuring peak performance when you need it most.

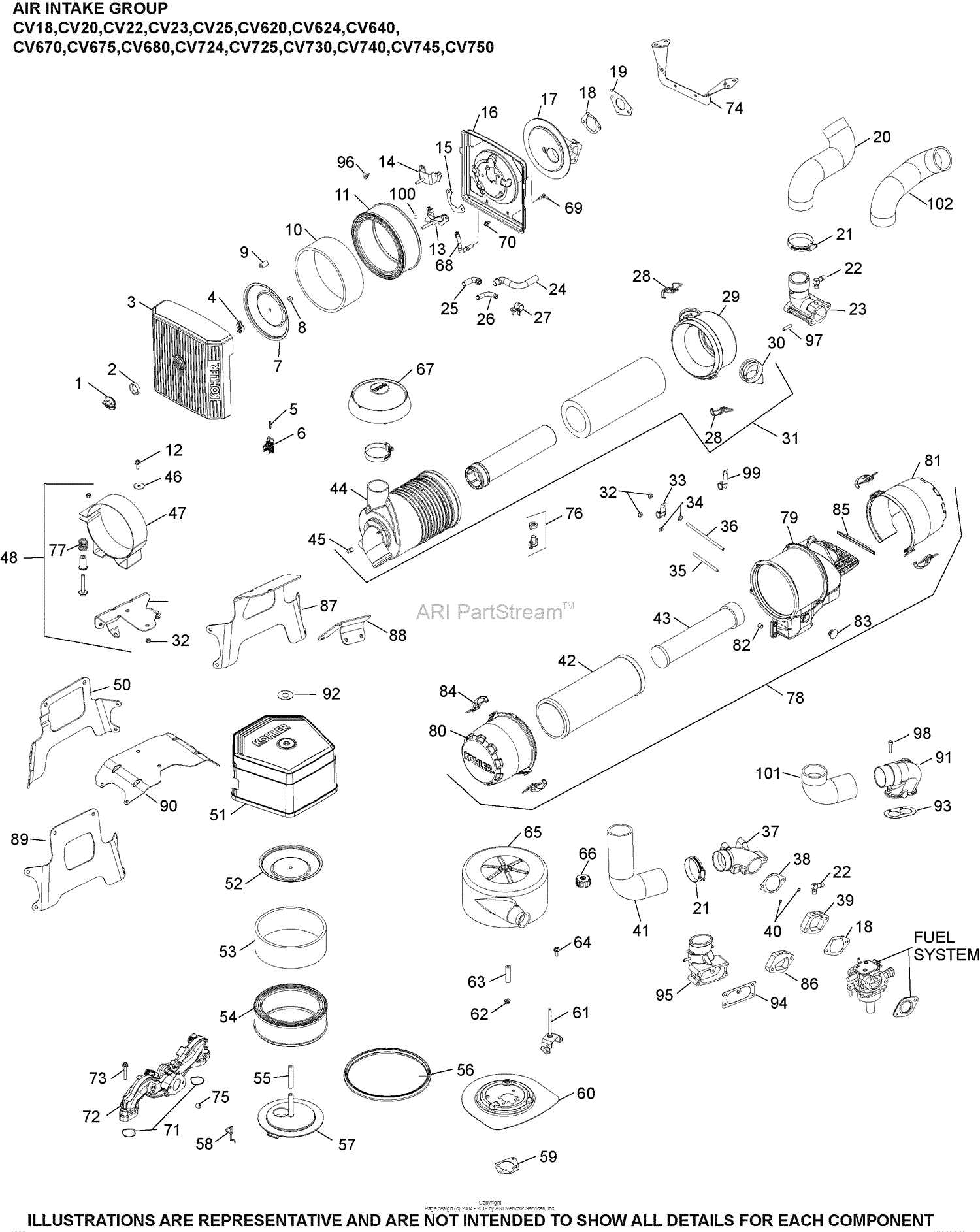

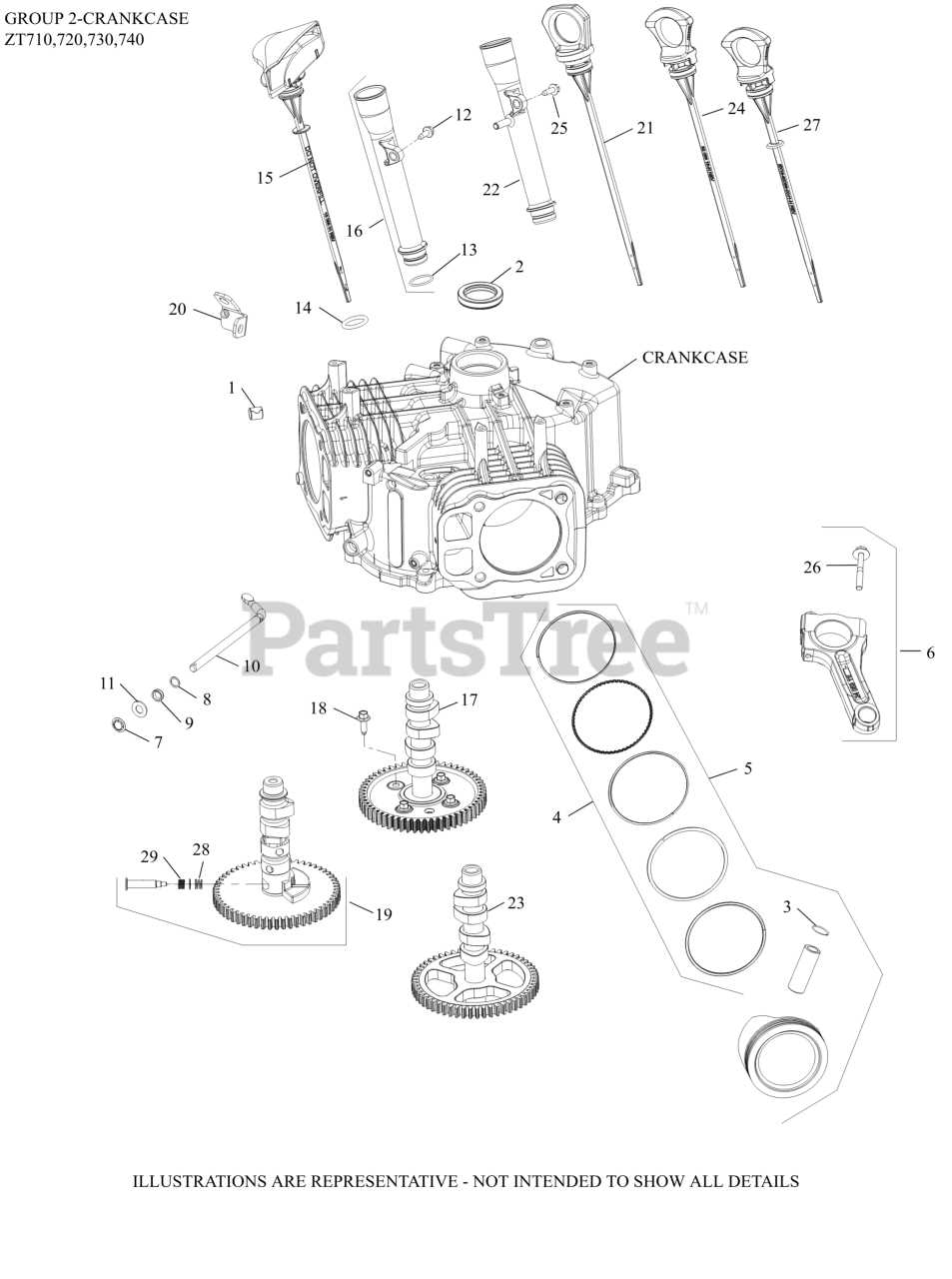

How to Identify Key Components for Repair

Recognizing the essential components of your machinery is the first step towards effective repairs. With a clear understanding of which sections require attention, you can avoid unnecessary disassembly and focus on the areas that need the most care. Identifying the correct components early ensures faster repairs and helps maintain optimal performance.

Visual Inspection for Damage

A thorough visual check is one of the most effective ways to spot worn or damaged components. Look for signs such as cracks, corrosion, or loose parts. These issues often indicate the need for replacement or adjustment. Familiarizing yourself with common problem areas in the machinery can help you quickly detect such damage.

Referencing the Maintenance Manual

Another valuable tool in identifying crucial components is the maintenance guide. By cross-referencing the machine’s layout with the manual, you can pinpoint areas that are prone to wear. This reference can help you understand the function of each part, allowing you to assess its condition and make informed decisions about repairs.

Tips for Maintaining Your Equipment

Proper maintenance is essential for ensuring the longevity and performance of your machinery. Regular upkeep prevents major issues and keeps the equipment running smoothly, reducing the need for costly repairs. By following a few key tips, you can maintain peak performance and extend the lifespan of your machine.

Regular Cleaning and Inspection

Cleaning your equipment after each use helps prevent dirt and debris from accumulating, which can cause wear over time. A routine inspection allows you to catch any potential issues early. Check for signs of damage, such as loose bolts or frayed cables, and address them before they lead to more significant problems.

Lubrication and Component Care

Keeping moving parts properly lubricated is crucial for reducing friction and preventing premature wear. Follow the manufacturer’s recommendations on the type of lubricant to use and how often to apply it. Pay special attention to high-use components, ensuring they remain in good working condition for optimal operation.