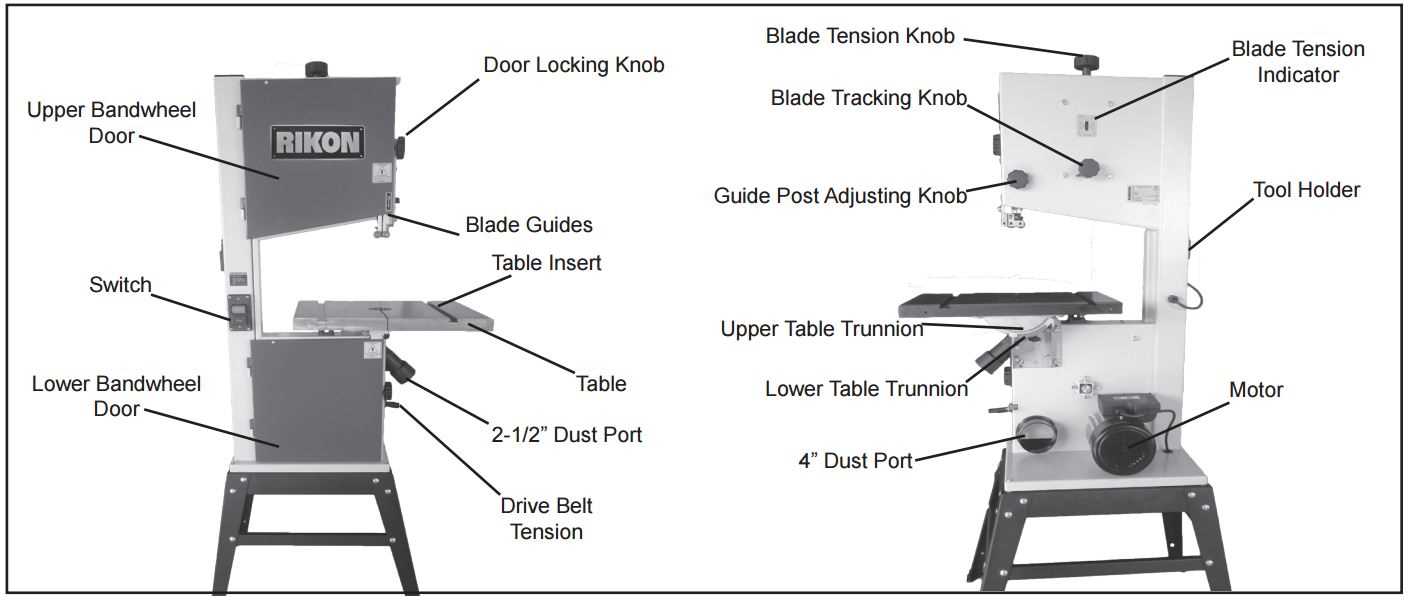

Every complex machinery involves various elements that work together to ensure smooth operation. Identifying and understanding these individual components is crucial for anyone using or maintaining such equipment. Whether you are a professional or a hobbyist, knowledge of these parts allows for better handling and troubleshooting.

In this section, we will explore the crucial elements that make up cutting equipment, their roles, and how to identify each part in the assembly. Proper maintenance and repair depend on understanding these components, as each plays a specific role in the overall functionality of the tool. Knowing how each part interacts will ensure both optimal performance and longevity.

Essential Band Saw Components Explained

Understanding the fundamental elements that make up cutting machinery is key to ensuring proper operation and effective maintenance. These components are the building blocks that allow the tool to perform its intended function efficiently and safely. Each part is designed to contribute to the overall performance, and knowing how they work together can prevent errors and enhance longevity.

Key Components and Their Functions

Among the most crucial elements is the cutting mechanism, which is responsible for delivering precision during operation. This part must be properly aligned to ensure clean and accurate cuts. The drive system powers the machinery, providing the necessary force to move components in sync. Without it, the tool would be unable to operate effectively.

Maintenance and Care Tips

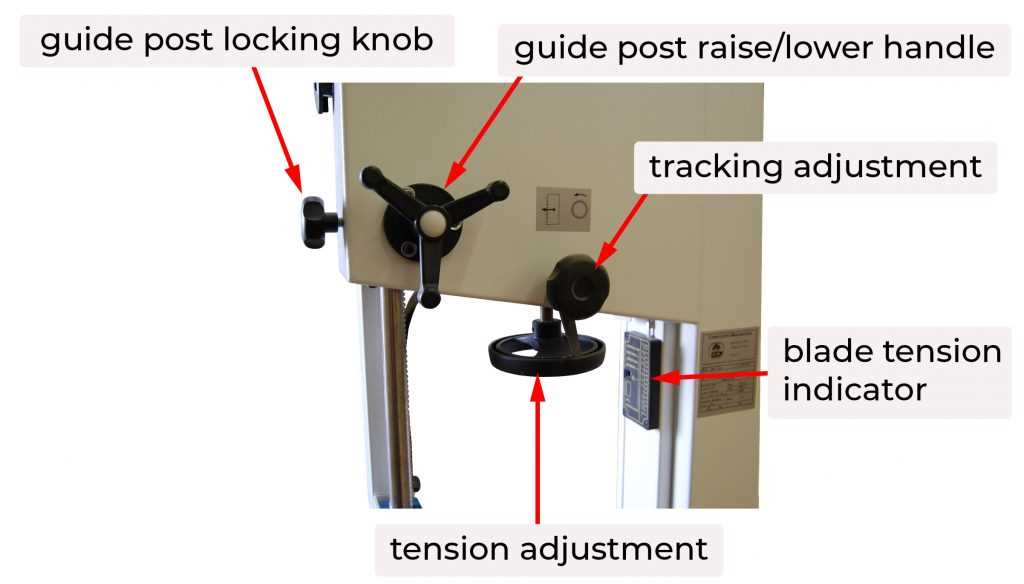

Regular maintenance of these components is essential to avoid wear and tear. It is important to inspect the tensioning system for proper adjustment and ensure that the guide rollers are functioning smoothly. Proper lubrication and cleaning will also help in prolonging the lifespan of each part. Routine checks can prevent breakdowns and costly repairs, allowing for more consistent performance over time.

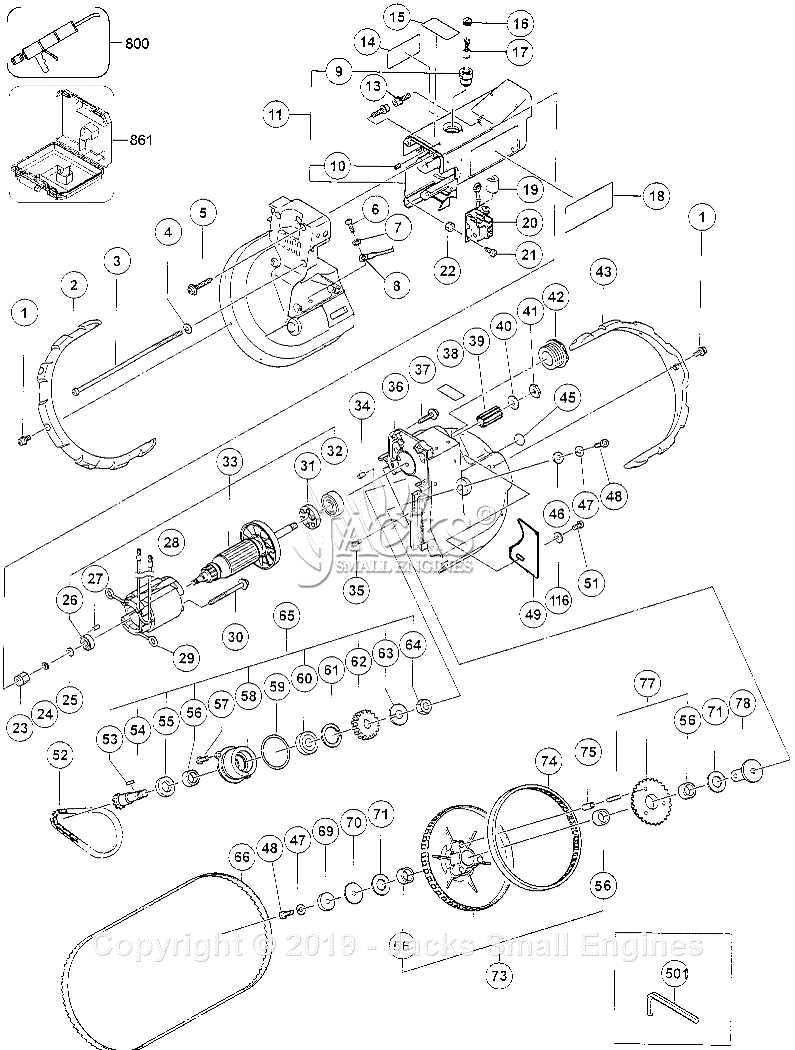

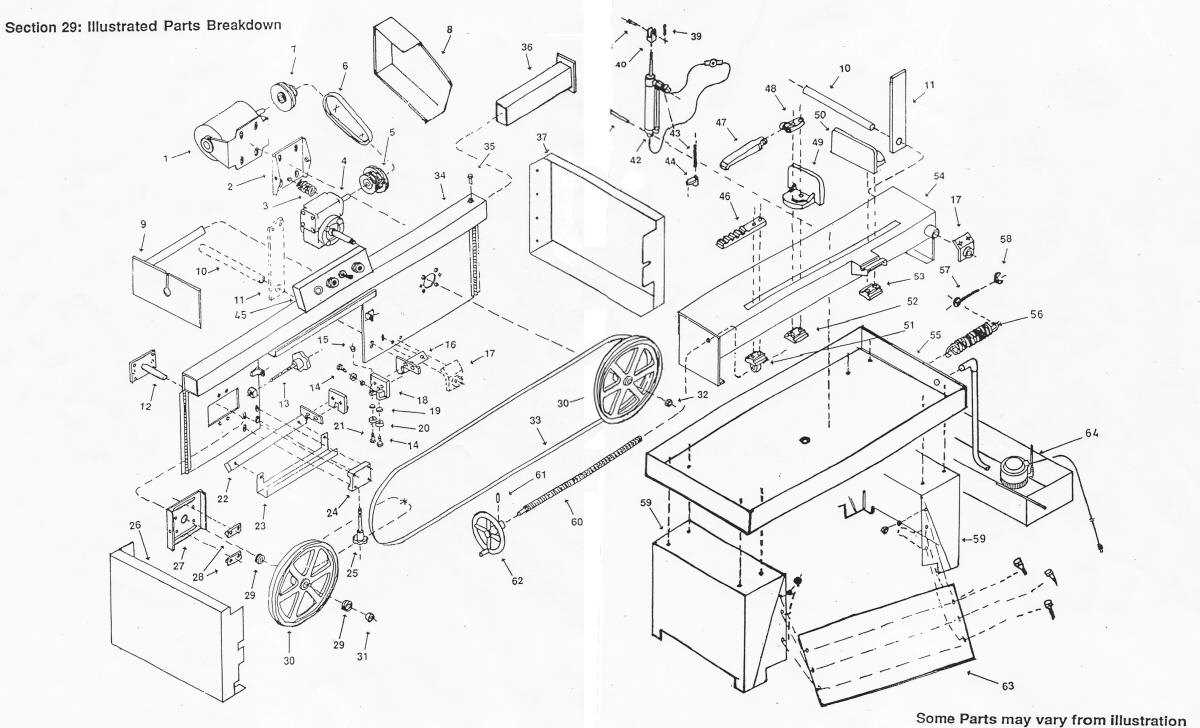

How to Read a Band Saw Parts Diagram

Interpreting the visual representation of a cutting tool’s components can significantly enhance your understanding of its construction and operation. These illustrations provide a detailed overview of the tool’s key elements, helping users identify parts and understand their relationships. Knowing how to read these diagrams allows for better troubleshooting, maintenance, and repair decisions.

Each component is typically labeled and positioned according to its location in the machine. Focus on identifying the main sections and how they interact with one another. For example, look for the power source, movement controls, and cutting elements in the diagram. By following the connections between these parts, you can better understand the assembly and detect potential issues more effectively.

Maintaining Your Band Saw Parts

Proper upkeep of cutting machine components is essential to ensure longevity and optimal performance. Regular care helps prevent unnecessary wear and tear, reduces the likelihood of malfunctions, and maintains the quality of work. Each element of the tool requires specific attention to keep it functioning smoothly and efficiently over time.

Regular Inspection and Cleaning

Consistent inspections are vital for identifying signs of wear and detecting potential issues before they escalate. Check the movement components for smooth operation and ensure that there is no build-up of debris or dust. Cleaning the machine regularly will prevent parts from becoming clogged, which could impede the performance of the entire system.

Lubrication and Tension Adjustments

Ensuring that the key components are properly lubricated is critical to reduce friction and avoid damage. In addition, regularly adjusting the tension on moving elements will prevent strain and ensure the correct operation of the machinery. Tightening or loosening parts as necessary keeps them in optimal working condition.