Every professional workstation relies on durable equipment that ensures comfort and efficiency. Knowing how various components work together is essential for proper maintenance and repair. Whether you’re fixing or upgrading, understanding the structure is crucial for keeping the setup functional over time.

Identifying individual elements allows for precise troubleshooting and helps extend the lifespan of your equipment. From mechanical features to hydraulic systems, each piece plays an important role in the overall performance. Familiarity with these components not only enhances the user experience but also prevents costly breakdowns.

By mastering the basic functions and common issues, you’ll be equipped to handle minor repairs or adjustments. A solid understanding can save time and money, making maintenance less of a hassle and ensuring reliable use in any environment.

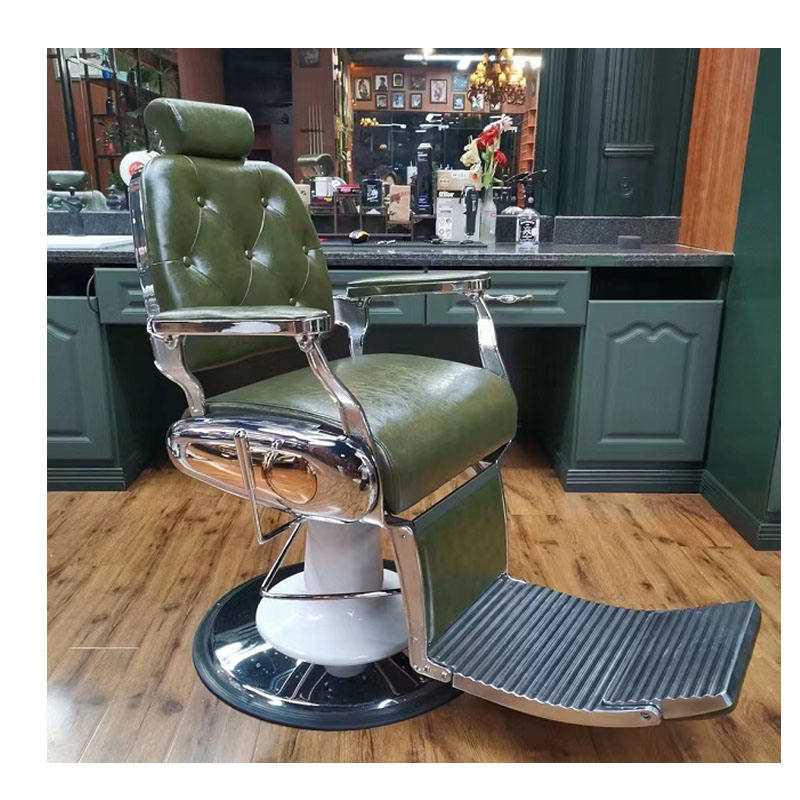

Understanding the Key Components of a Barber Chair

The functionality of professional equipment depends on the precise coordination of its elements. Each feature contributes to the overall comfort, usability, and durability of the setup. Whether adjusting height, tilt, or reclining functions, the interaction of these key components ensures optimal performance for users and clients alike.

Mechanical and Hydraulic Systems

The movement of the structure is typically controlled by a combination of hydraulic systems and mechanical components. These systems allow smooth adjustments in height and angle, ensuring comfort for people of varying sizes. The hydraulic mechanism, often controlled by a foot pedal or lever, provides the force needed to modify the position of the seat efficiently.

Frame and Base Construction

The base and frame are the backbone of the entire setup, providing stability and strength. These components are designed to handle heavy loads and frequent adjustments, ensuring long-lasting durability. Strong construction materials such as metal or reinforced plastic are commonly used to withstand wear and tear from constant use, ensuring reliability and safety.

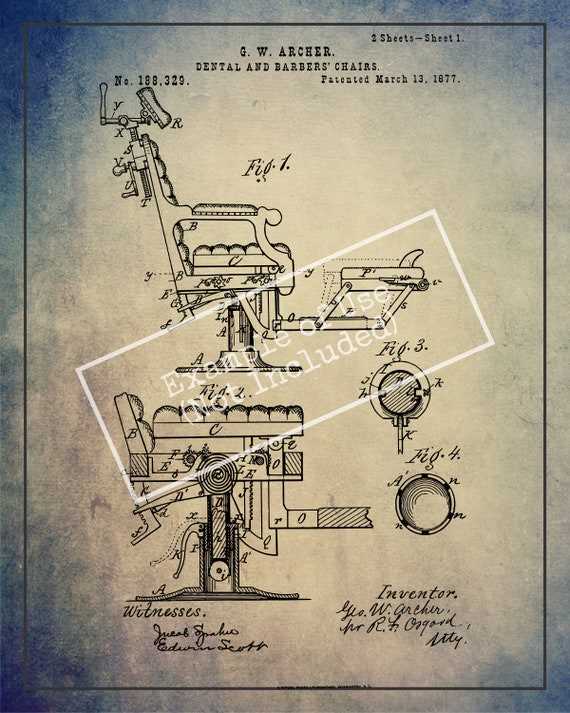

How to Identify Parts on the Diagram

Understanding the layout of complex systems can be challenging without a visual reference. However, once you know how to read the various labels and symbols, it becomes easier to identify individual elements. Recognizing each component in the visual representation allows for quicker repairs and more efficient maintenance.

Start by focusing on the primary functional sections, such as the adjustable mechanisms or the support structures. These will typically be highlighted or annotated to indicate their importance in the overall operation. Additionally, pay attention to arrows or lines that show movement or flow, as they help clarify how parts work together.

Familiarity with common symbols and their meanings can significantly speed up the process of understanding the visual layout. Once you’ve learned how the individual elements fit into the bigger picture, troubleshooting and replacements become simpler tasks.

Common Issues and Fixes for Barber Chairs

Over time, equipment used in high-demand environments can face a variety of issues that affect its performance. Recognizing these common problems and knowing how to resolve them can extend the life of your setup and improve overall functionality. Many issues are simple to address with basic tools and some understanding of the system’s inner workings.

Unresponsive Height Adjustments

If the height adjustment feature becomes unresponsive, it may be due to a malfunctioning hydraulic system or a clogged valve. To fix this, first check for any visible damage to the control mechanism or hydraulic lines. If no visible issues are found, consider draining and replacing the hydraulic fluid or inspecting the pump for wear and tear.

Worn-out Reclining Mechanism

The reclining function often experiences strain from regular use, leading to a slow or ineffective motion. This can be fixed by lubricating the joints and inspecting the reclining lever for damage. In some cases, parts may need to be replaced if they are beyond repair, such as worn-out springs or broken gears.