When dealing with any firearm, a clear understanding of its individual components is essential for proper maintenance and troubleshooting. Knowing how each element fits together allows for more effective care, reduces the likelihood of errors, and can extend the lifespan of the weapon. In this section, we focus on the internal assembly and functional parts of a specific model, providing insights into their arrangement and operation.

Exploring the inner workings is not just for professionals; it benefits every enthusiast who aims to enhance their shooting experience. Whether you are performing routine maintenance or addressing issues, recognizing how different sections interact is crucial for optimal performance.

Identifying key components and understanding their roles can simplify repairs and upgrades. This guide is designed to break down the essential parts, helping you navigate through the structure with ease and confidence.

Understanding the Beretta A400 Components

When examining the inner structure of a firearm, it’s essential to recognize the key elements that work together to ensure smooth operation. Each section plays a vital role, from the loading mechanism to the firing system, contributing to the overall functionality and reliability of the weapon. Understanding how these components are designed and interact is crucial for anyone seeking to maintain or repair the firearm efficiently.

The main sections typically include the trigger assembly, the gas system, and the magazine components, among others. These parts are engineered to perform specific tasks that allow for proper firing, reloading, and cycling of ammunition. By becoming familiar with these areas, users can troubleshoot issues, perform regular maintenance, and make informed decisions about any necessary repairs.

Additionally, recognizing the arrangement of these components allows for a deeper understanding of the firearm’s performance and handling. Whether you’re a beginner or an experienced user, a solid grasp of the core elements can improve both safety and efficiency during use.

How to Read the A400 Parts Diagram

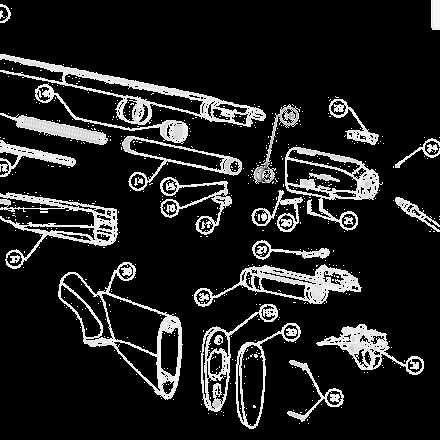

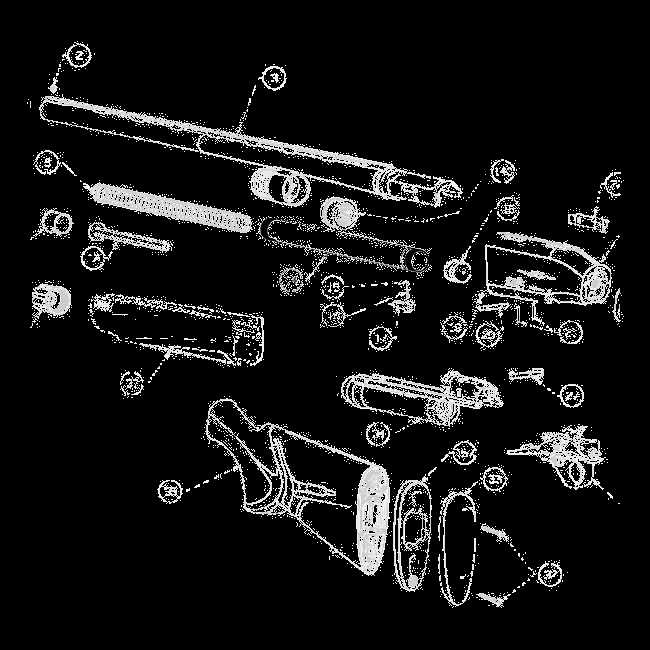

Understanding the layout of a firearm’s internal components requires careful attention to detail. A visual representation can provide a clear overview of how each element is positioned and interacts with the others. By breaking down the illustration step by step, users can identify individual pieces and learn their function within the overall mechanism.

To begin, it’s essential to familiarize yourself with the labeling system used in such diagrams. Each part is typically numbered or color-coded for easy reference. Understanding the symbols or annotations next to each component can also provide additional context, such as material specifications or installation instructions.

Once you grasp the basics, you can use the diagram as a valuable tool for identifying problems or performing maintenance. By matching each part to its corresponding label, you can quickly pinpoint worn or damaged components, making repairs much more straightforward.

Common Issues with Beretta A400 Parts

While firearms are built to last, certain components may experience wear or malfunction over time, leading to potential issues. These problems can often stem from regular use, poor maintenance, or manufacturing defects. Identifying these common concerns early can save time and money when it comes to repairs or replacements.

One of the most frequent problems is related to the gas system, which can become clogged or worn out. This can result in improper cycling or failure to eject spent shells. Another common issue involves the trigger mechanism, where components may become sticky or fail to reset properly, causing malfunctions during use.

Additionally, magazine and loading issues are not uncommon. Dirt, debris, or worn springs can lead to feeding problems, causing jams or misfeeds. Regular cleaning and inspection can help prevent many of these issues, ensuring that the firearm continues to perform optimally.