Proper knowledge of the internal structure and individual elements of a cleaning device is essential for maintaining its performance and longevity. Recognizing how each part functions together ensures smooth operation and helps identify issues before they become more significant problems.

Exploring the structure of your appliance allows for better troubleshooting when the machine is not functioning as expected. Identifying where a malfunction originates can save time and effort during the repair process, preventing unnecessary replacements of functional parts.

Knowing the role of each element within the system also enhances care and maintenance. Regularly checking and cleaning each piece based on its design will improve the overall efficiency and extend the device’s life, ensuring it works at peak performance for a longer period.

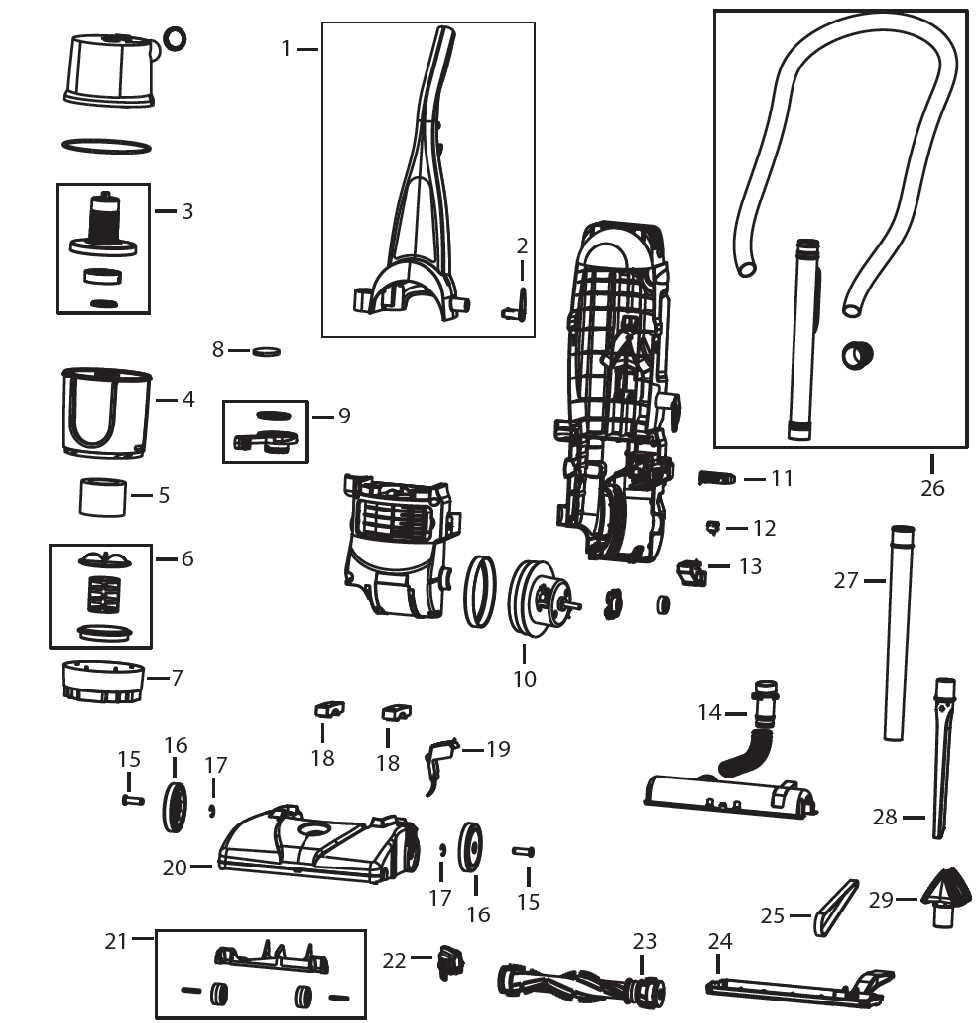

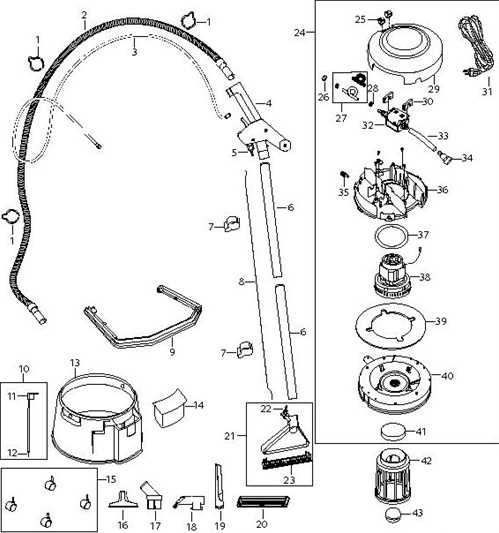

Understanding the Assembly of the Cleaner

The structure of any cleaning device is carefully designed to ensure efficient performance. Each individual component plays a crucial role in the overall function, working together to create a seamless cleaning experience. A clear understanding of how these elements are arranged and interact with each other is key to maintaining optimal functionality.

The assembly typically includes various sections, from the motor to the brushes, that are interlinked to perform specific tasks. Knowing the purpose of each section allows users to troubleshoot more effectively and avoid unnecessary repairs. Additionally, the organization of these components ensures that power is directed precisely where it’s needed, enhancing the cleaning process.

Familiarity with the assembly allows for better decision-making when it comes to cleaning, repairing, or replacing parts. Understanding how each element fits within the system ensures that the appliance remains efficient and can continue to meet your cleaning needs with minimal downtime.

Key Components of the Cleaning Model

Every cleaning device relies on a set of crucial elements that contribute to its efficient operation. These components work in harmony to ensure the machine performs at its best, each fulfilling a specific function necessary for effective cleaning. Understanding these primary features helps users maintain and troubleshoot the appliance more easily.

Essential elements include the motor, water tank, suction system, and cleaning nozzles. The motor drives the suction and water flow, while the tank stores the liquid necessary for cleaning. The suction system pulls dirt and debris, and the nozzles focus the water onto the surfaces being cleaned. Each of these components is integral to the overall performance of the device.

Familiarity with these key components enables proper maintenance, allowing users to identify and address issues promptly. Regular inspection and care of these parts will ensure the machine continues to perform effectively over time, reducing the likelihood of breakdowns and extending its lifespan.

How to Identify Faulty Parts

Recognizing malfunctioning components is essential for effective troubleshooting and repair. When a cleaning device stops functioning as expected, understanding how to pinpoint the source of the issue can save time and money. By carefully examining the appliance’s main sections, users can identify faulty areas that need attention.

The first step in identifying problems is to listen for unusual sounds or check for decreased suction. These are often indicators of issues within the motor or suction system. Additionally, inspect the water flow; if there is a blockage or reduced pressure, the water tank or hose might be the source of the issue. Another common problem is worn-out brushes, which can affect cleaning efficiency.

Visually examining each component for signs of wear, cracks, or blockages will help detect faults. A thorough inspection of the motor, water intake, and any seals or connections is recommended. If parts show signs of damage or excessive dirt buildup, they should be cleaned or replaced to restore full functionality.

Diagnosing and Replacing Malfunctioning Items

When an appliance stops performing as expected, diagnosing the cause of the issue is the first step toward restoring functionality. Identifying faulty components and knowing how to replace them can prevent unnecessary repairs and help maintain optimal operation. A systematic approach ensures that all potential problems are addressed efficiently.

Step 1: Identifying the Issue

Before replacing any component, carefully inspect the machine to determine where the problem lies. Common signs of malfunction include:

- Reduced suction or no suction at all

- Unusual sounds or vibrations during operation

- Leaks or poor water flow

- Visible wear, cracks, or blockages in key parts

Step 2: Replacing the Faulty Component

Once the problematic element is identified, follow these general steps to replace it:

- Unplug the appliance and ensure it is safe to handle.

- Carefully disassemble the device, starting with the most accessible parts.

- Remove the faulty component, taking note of how it fits into the system.

- Install the new part, ensuring it is properly connected and secured.

- Reassemble the device and test it to confirm that the issue has been resolved.

Always refer to the manufacturer’s instructions for specific guidelines on replacing parts. Regular maintenance and timely replacement of worn components can extend the life of the device and keep it performing at its best.

Steps for Proper Maintenance

To ensure a cleaning device continues to perform effectively, regular maintenance is essential. Routine care helps prevent malfunctions, extends the lifespan of the appliance, and ensures consistent performance. By following a few straightforward steps, users can maintain their equipment in top condition without the need for frequent repairs.

Start by regularly checking and cleaning the major components, such as the motor, water tank, and hoses. Removing dirt buildup and ensuring that no parts are clogged will help the machine run more efficiently. It’s also important to inspect for signs of wear or damage, which can affect the device’s performance.

In addition to cleaning, periodically replace any parts that show signs of excessive wear or damage. This could include brushes, filters, or seals that may need to be refreshed to maintain optimal operation. Lastly, store the device in a clean and dry place to prevent dust buildup and avoid environmental factors that could affect its functionality.