When maintaining heavy machinery, having a clear view of the mechanical components and how they interact is essential. Identifying the various parts and their functions can make the repair process smoother and more efficient. Understanding the layout and assembly of these systems helps operators and technicians manage maintenance tasks effectively.

Accurate visualization of each section aids in identifying potential issues and understanding the required repairs. This approach minimizes downtime and prevents further damage to the equipment. With detailed breakdowns, the repair process becomes more systematic, allowing for quicker fixes and optimal performance of the machinery.

Having a thorough grasp of these systems ensures that operators can address common issues quickly and with confidence. With a well-organized reference, managing the maintenance needs of complex machinery becomes a more straightforward task.

Understanding Excavator Component Layout

When working with complex construction equipment, it’s crucial to have an in-depth understanding of its structure. Each machine consists of various systems that work together, and knowing the function of each element ensures smoother operation and quicker troubleshooting. This section will break down the essential components that keep the machine running efficiently, focusing on their roles and how they interconnect.

Main Systems and Their Functions

Every major system within an excavator has a distinct role. For example, the hydraulic system is responsible for powering key functions like lifting, digging, and steering, while the engine drives the overall operation. Other systems, such as the electrical and cooling systems, support the primary functions by ensuring energy and temperature control. A deep understanding of how these systems interact is vital for maintaining optimal performance.

Common Wear and Tear Areas

Regular usage inevitably leads to certain components experiencing wear. Hydraulic seals, for instance, are prone to damage due to constant pressure and movement. Similarly, engine parts can degrade over time, affecting the overall efficiency of the machinery. By recognizing the signs of wear early, operators can take preventative measures and reduce downtime.

Detailed Component Breakdown for Excavator

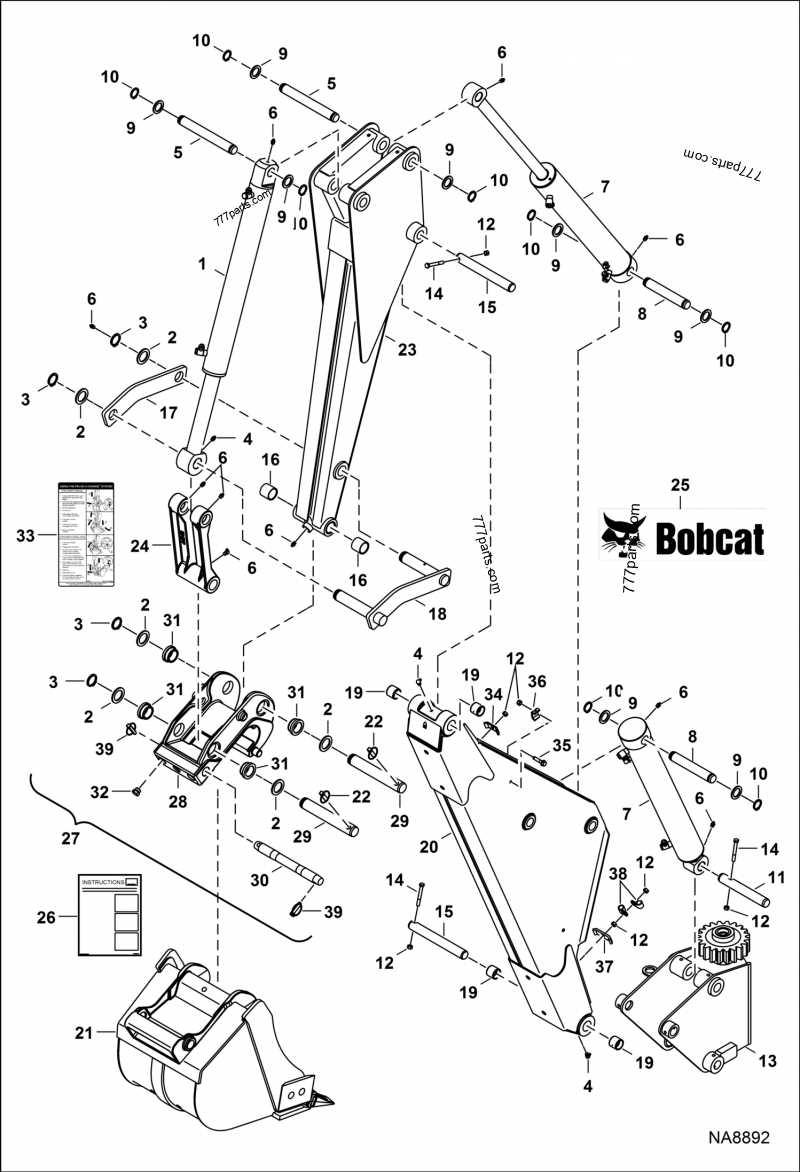

A comprehensive breakdown of the equipment’s individual elements is crucial for identifying and understanding how each piece fits into the larger system. By having access to a visual representation of the machine’s configuration, operators and technicians can better diagnose issues and perform maintenance. This detailed guide provides an overview of the key sections and their relationships, making it easier to work on the machinery effectively.

Hydraulic and Power Systems

The hydraulic system is integral to the machine’s functionality, powering critical movements such as digging, lifting, and swinging. Understanding the layout of pumps, valves, and cylinders within this system allows for more efficient troubleshooting and repair. Additionally, the powertrain, consisting of the engine, transmission, and drive components, plays a crucial role in driving the machine’s performance. Both of these systems rely heavily on precise coordination.

Structural and Support Elements

Structural components, such as the frame and arm, provide the foundation for the machine’s various systems. These parts must be robust enough to withstand heavy loads and stresses during operation. Additionally, support elements like bearings, joints, and fasteners hold everything in place, ensuring stability and safety while in use. Understanding the layout of these structural pieces aids in identifying potential vulnerabilities and improving the durability of the equipment.

Common Issues and Solutions for Excavator Components

Heavy machinery often faces a range of challenges due to wear, environmental factors, and operational demands. Identifying common issues early on can help prevent more significant damage and costly repairs. This section highlights frequent problems encountered with various components and provides practical solutions to address them effectively.

Hydraulic System Leaks

One of the most common issues with excavators is hydraulic system leaks. These leaks often occur around seals, hoses, and fittings due to high pressure and constant movement. To resolve this issue, inspect the hydraulic lines regularly for signs of wear or cracks. Replacing damaged seals and hoses promptly can prevent further loss of fluid and ensure that the system operates efficiently.

Engine Overheating

Engine overheating is another frequent problem, particularly when the cooling system is not functioning properly. A clogged radiator or malfunctioning coolant pump can restrict airflow and reduce cooling efficiency. To prevent overheating, ensure that the radiator is clean, and regularly check the coolant levels and condition. If the engine continues to overheat, consider replacing the thermostat or inspecting the cooling fan for any obstructions.