Every heavy machinery model consists of numerous interconnected elements that ensure optimal performance and durability. Having a clear understanding of these parts and their layout can make a significant difference when it comes to maintenance and repairs. Accurate visual representations are essential for technicians and machine operators alike, offering a comprehensive view of the assembly.

Proper knowledge of the system’s structure allows for quicker identification of worn-out or damaged components. This can save time and prevent unnecessary repairs, leading to a longer lifespan for the equipment. Furthermore, such detailed guides enable users to make informed decisions about upgrades or replacements.

Familiarizing yourself with the components helps in troubleshooting problems more efficiently. It can also enhance safety, ensuring the correct handling and installation of essential elements to avoid costly mistakes and downtime.

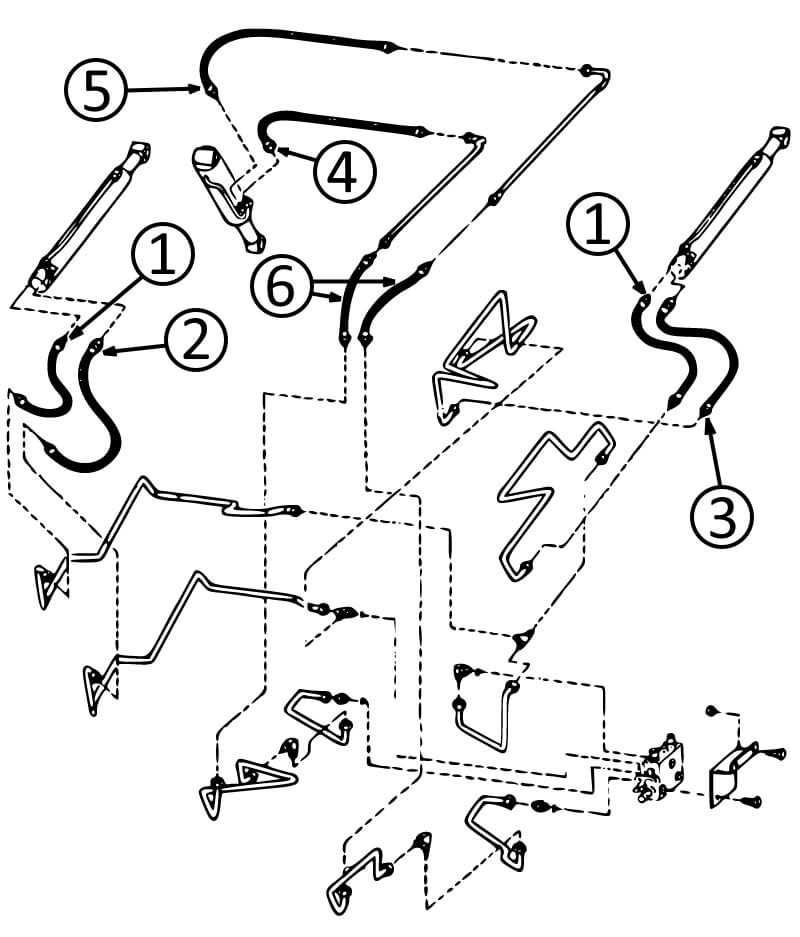

Understanding Machine Assembly Layout

Heavy machinery is made up of various components, each playing a specific role in the overall functionality of the system. A clear understanding of how these elements are arranged and interact with one another is crucial for proper maintenance and efficient operation. Knowing where each part fits into the bigger picture helps identify issues quickly and ensures that repairs are carried out accurately.

Component Arrangement and Function

The structure of the machine includes a wide array of mechanical, hydraulic, and electrical components. Each element must be placed in its designated position to work in harmony with the others. Understanding this layout allows for faster troubleshooting when issues arise and makes it easier to assess which parts need attention.

Importance of Correct Assembly

Correct assembly is key to preventing operational failures. Misplaced or improperly installed components can lead to inefficiencies, increased wear, or even breakdowns. A well-organized layout ensures that each part performs its intended function and contributes to the smooth running of the entire machine.

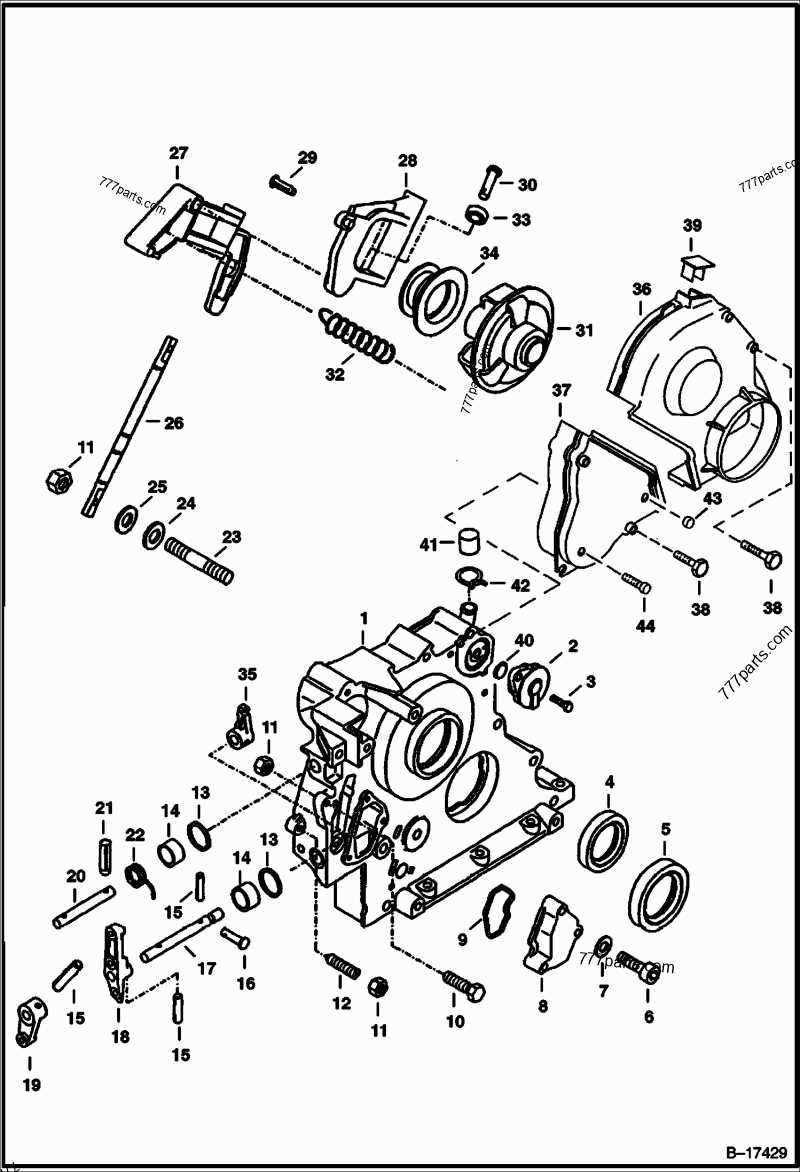

Essential Components of Heavy Machinery

Each piece of heavy equipment is built around a set of core components that allow it to function efficiently. These essential elements are designed to work together to provide power, movement, and stability, making them crucial for the overall operation. Understanding their role is vital for anyone looking to maintain or repair the machinery effectively.

Key Mechanical Elements

The mechanical systems include parts such as the engine, transmission, and drive mechanisms. These components work in unison to generate the necessary power and direct it to various functional areas of the machine. Their proper maintenance is crucial to ensure that the equipment operates smoothly and efficiently over time.

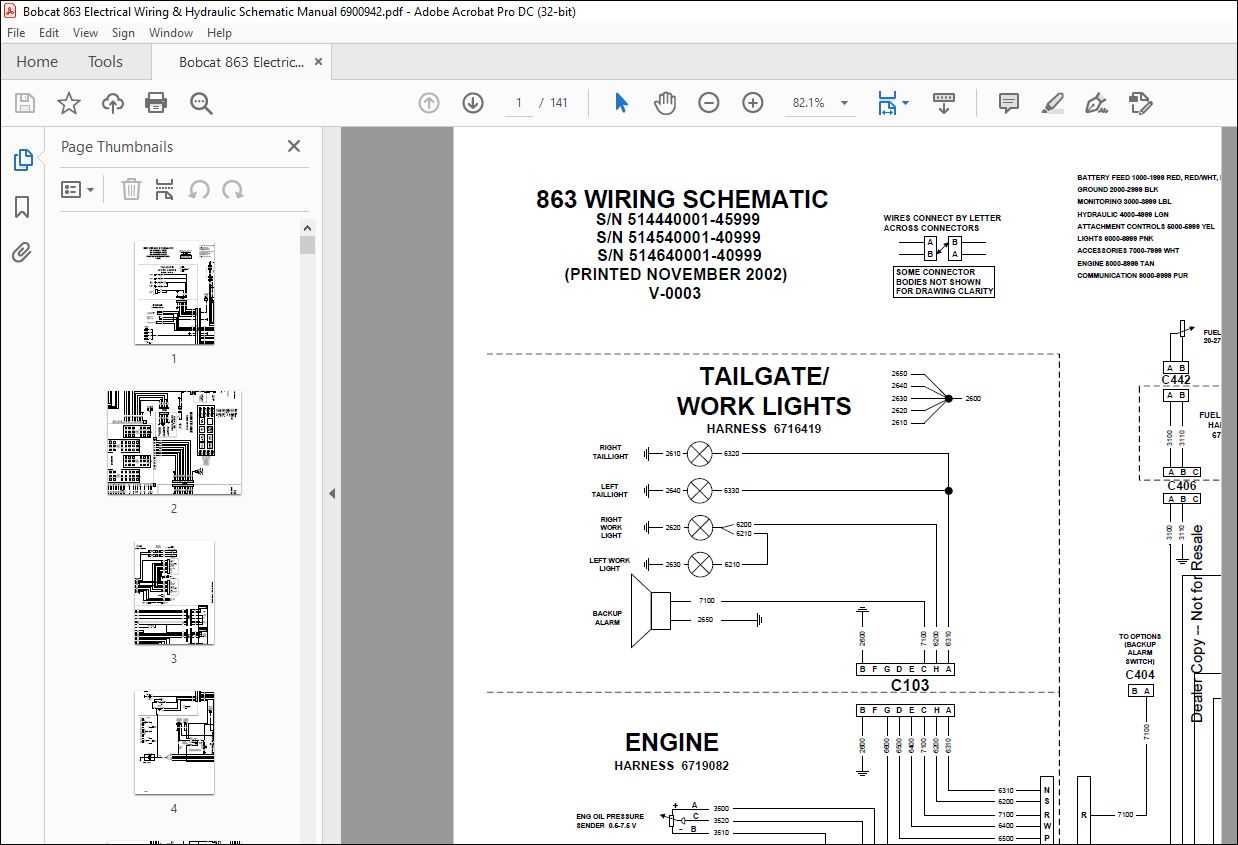

Hydraulic and Electrical Systems

Hydraulic systems are essential for controlling movements like lifting and tilting, while the electrical system powers essential controls and sensors. These systems are intricately designed to ensure precise operation and require careful inspection to prevent malfunctions that could compromise performance.

How to Read Machinery Assembly Layout

Understanding a schematic or blueprint for a machine requires familiarity with its symbols, structure, and reference points. These visual representations are designed to clearly outline the position and connection of each element within the system. By reading them correctly, you can easily identify each component and its relationship with others, helping streamline maintenance and repairs.

Interpreting Symbols and Notations

Most technical illustrations use standardized symbols to represent different parts of the machine. These symbols help technicians identify each component without confusion. Along with symbols, specific notations often indicate measurements, part numbers, and additional details that are important for accurate identification and replacement.

Understanding Relationships and Placement

It’s crucial to understand how the various parts are interconnected. These layouts typically display the flow of energy or fluid between components, allowing you to assess how each one contributes to the overall function. Pay attention to arrows or lines that show movement or force, as they can highlight the role and importance of individual elements within the system.