Understanding the structure and functionality of complex machinery is essential for efficient use and maintenance. Proper knowledge of each individual element can help ensure that the equipment operates smoothly and lasts longer. By examining the specific components and their interconnections, operators can perform accurate diagnostics, identify wear, and make repairs effectively.

In this article, we will explore a detailed breakdown of the different parts that make up a particular piece of construction machinery. With this understanding, users will be able to navigate technical diagrams, identify critical sections, and manage ongoing maintenance tasks more confidently. Whether you’re a seasoned operator or new to the field, this guide will offer valuable insights into how the system works as a whole.

Clear identification and familiarity with each component will not only enhance operational efficiency but also reduce downtime and repair costs in the long run. The following sections will walk through the main components, offering a clear overview of their functions and how they work together to achieve optimal performance.

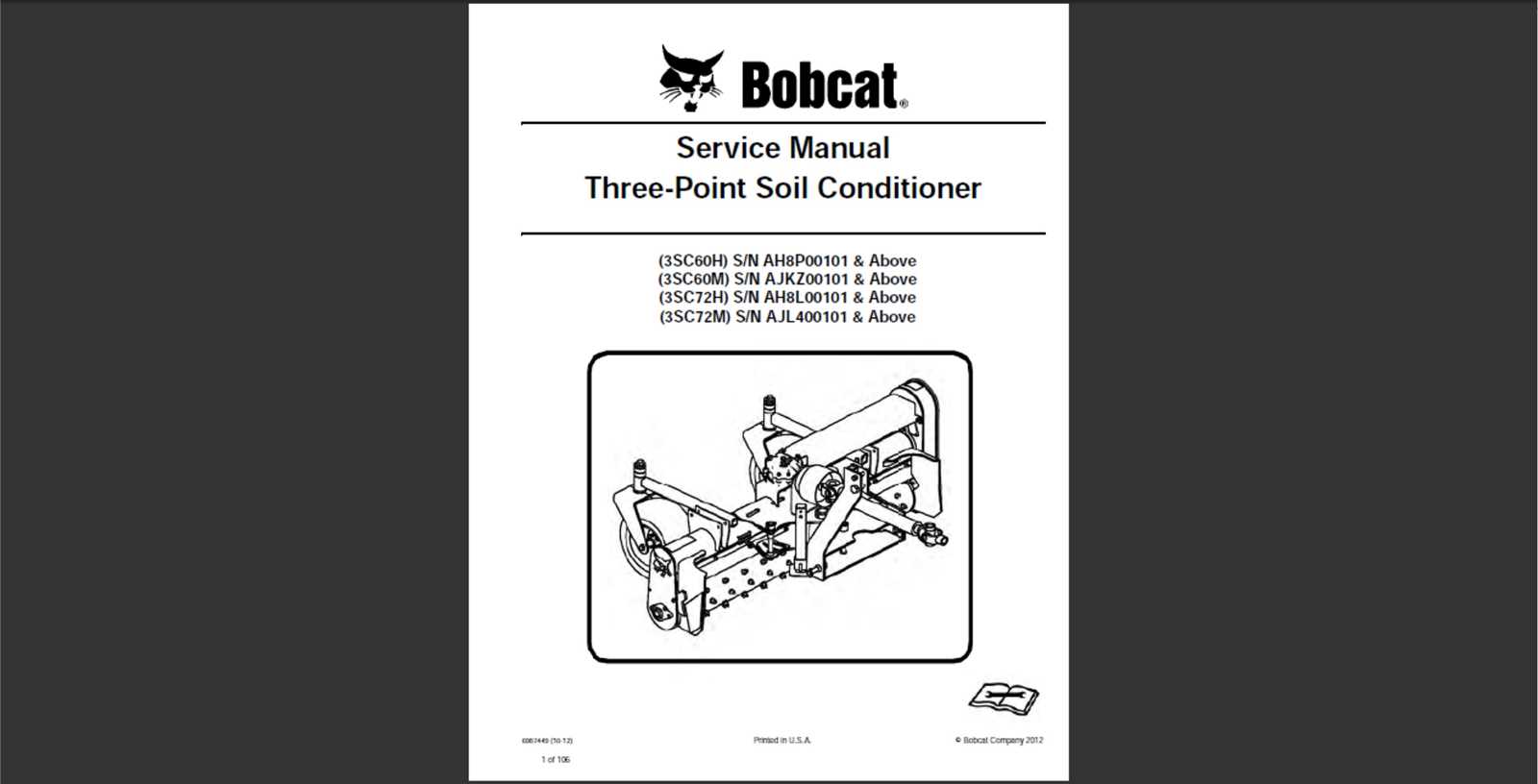

Understanding Bobcat Soil Conditioner Components

Efficient machinery relies on the seamless integration of its individual elements. Every component plays a crucial role in ensuring the machine functions correctly and performs its tasks without interruptions. Recognizing the specific function of each section allows for better maintenance and faster troubleshooting when issues arise.

This section will delve into the various key components that contribute to the overall performance of the equipment. From drive systems to attachments, each piece is designed to work together harmoniously, allowing the operator to achieve precise results. A clear understanding of these components ensures that maintenance tasks are completed efficiently and the machinery remains in top condition.

By gaining insight into how these parts are structured and interact, users will be equipped to make informed decisions regarding repairs, adjustments, and replacements. A thorough knowledge of the entire system minimizes the risk of costly errors and downtime, ultimately extending the life of the equipment.

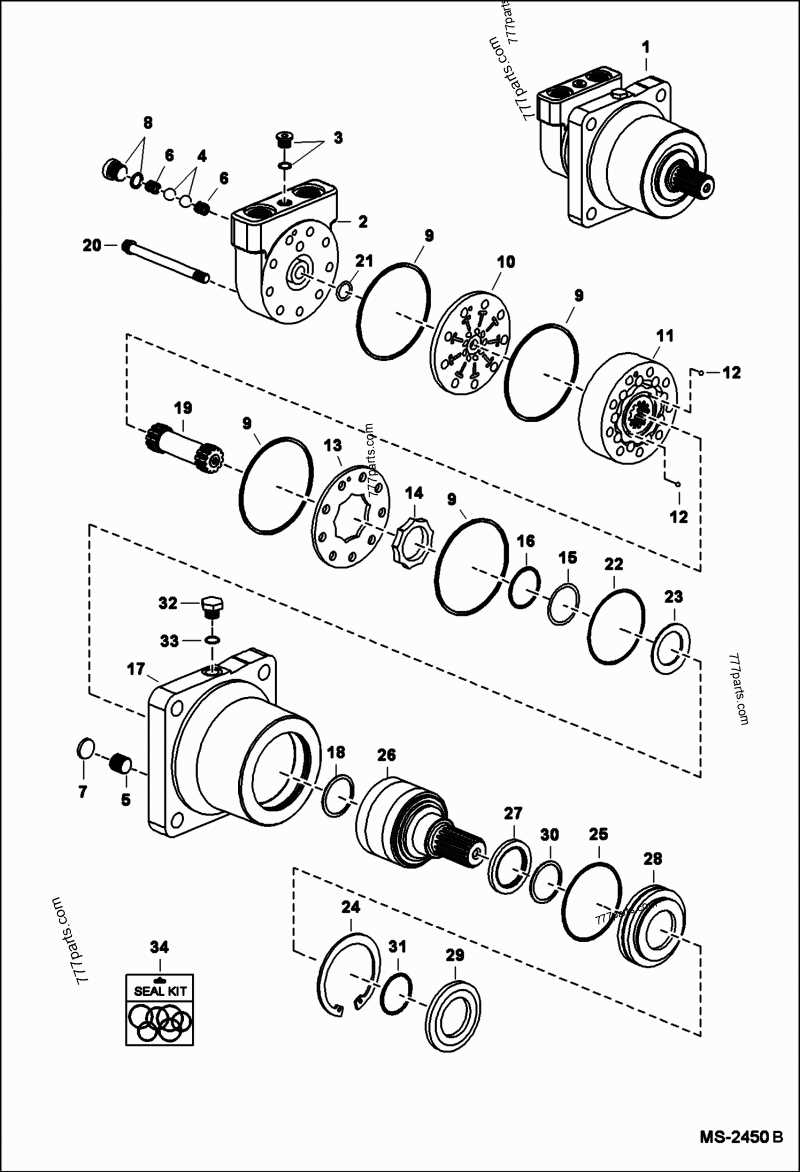

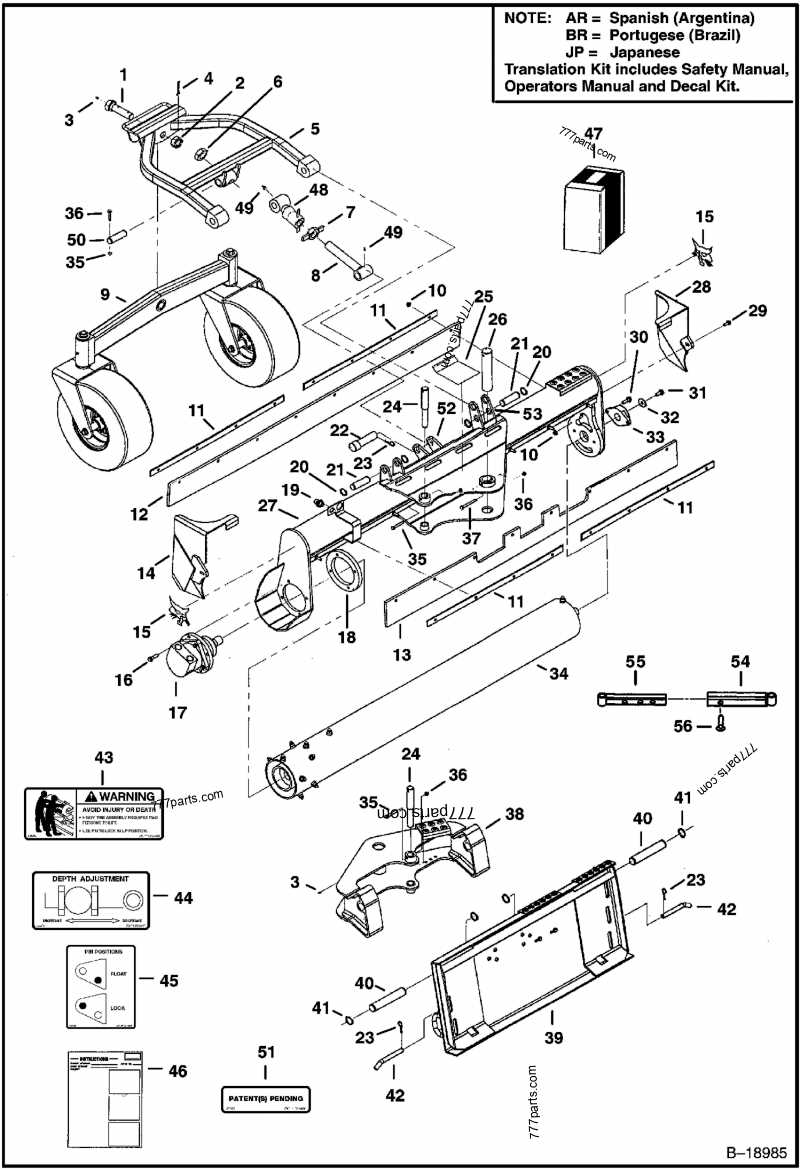

How to Identify Parts in the Diagram

Recognizing each individual component within a technical illustration is a vital skill for operators and maintenance personnel. The ability to quickly identify the various elements and understand their relationships within the system allows for accurate repairs and adjustments. Proper identification ensures that troubleshooting becomes more straightforward and reduces the likelihood of mistakes during the maintenance process.

To effectively interpret an illustration, it is essential to familiarize yourself with the layout and labeling conventions used. Each section typically includes clear markers, such as numbers or letters, that correspond to the relevant components. Understanding these markers and cross-referencing them with manuals or reference materials will help you pinpoint each piece in the system.

Another useful approach is to focus on the function of each part within the machinery. By knowing the role each element plays, you can better understand its placement and significance in the diagram. With practice, identifying the components becomes more intuitive, helping you navigate the system with ease and confidence.

Maintenance Tips for Bobcat Soil Conditioner

Regular upkeep is essential for ensuring that machinery operates at peak performance and remains durable over time. Routine maintenance tasks help prevent unexpected breakdowns and reduce the need for costly repairs. By staying on top of maintenance, operators can extend the life of their equipment and improve its efficiency on every job.

Start by performing regular inspections of the key components, looking for signs of wear, damage, or misalignment. Ensuring that all moving parts are properly lubricated and free from debris is crucial for smooth operation. Additionally, check fluid levels frequently and replace filters as needed to maintain the system’s overall functionality.

Keep a detailed log of all maintenance activities, including inspections and part replacements. This practice not only helps track the condition of the equipment but also allows for better planning of future maintenance tasks. Consistent care and attention to detail will keep the machine running smoothly and ready for the next task at hand.