When maintaining heavy equipment, having a clear and detailed reference of all mechanical parts is essential. Knowing where each component fits and how they interact ensures smooth operation and helps prevent costly mistakes during repairs. This knowledge is critical for anyone working with complex machinery, whether for routine maintenance or troubleshooting issues.

Having access to a visual representation of the structure allows operators and technicians to easily identify key parts, their functions, and proper placement. It also supports informed decision-making when replacing or adjusting components. These resources are indispensable for maximizing equipment lifespan and efficiency.

Understanding how the various elements work together within the system not only aids in resolving immediate problems but also promotes better preventive care. A clear breakdown of the machine’s internal workings equips users with the insight needed for optimal performance and longevity.

Understanding Bobcat T190 Parts Layout

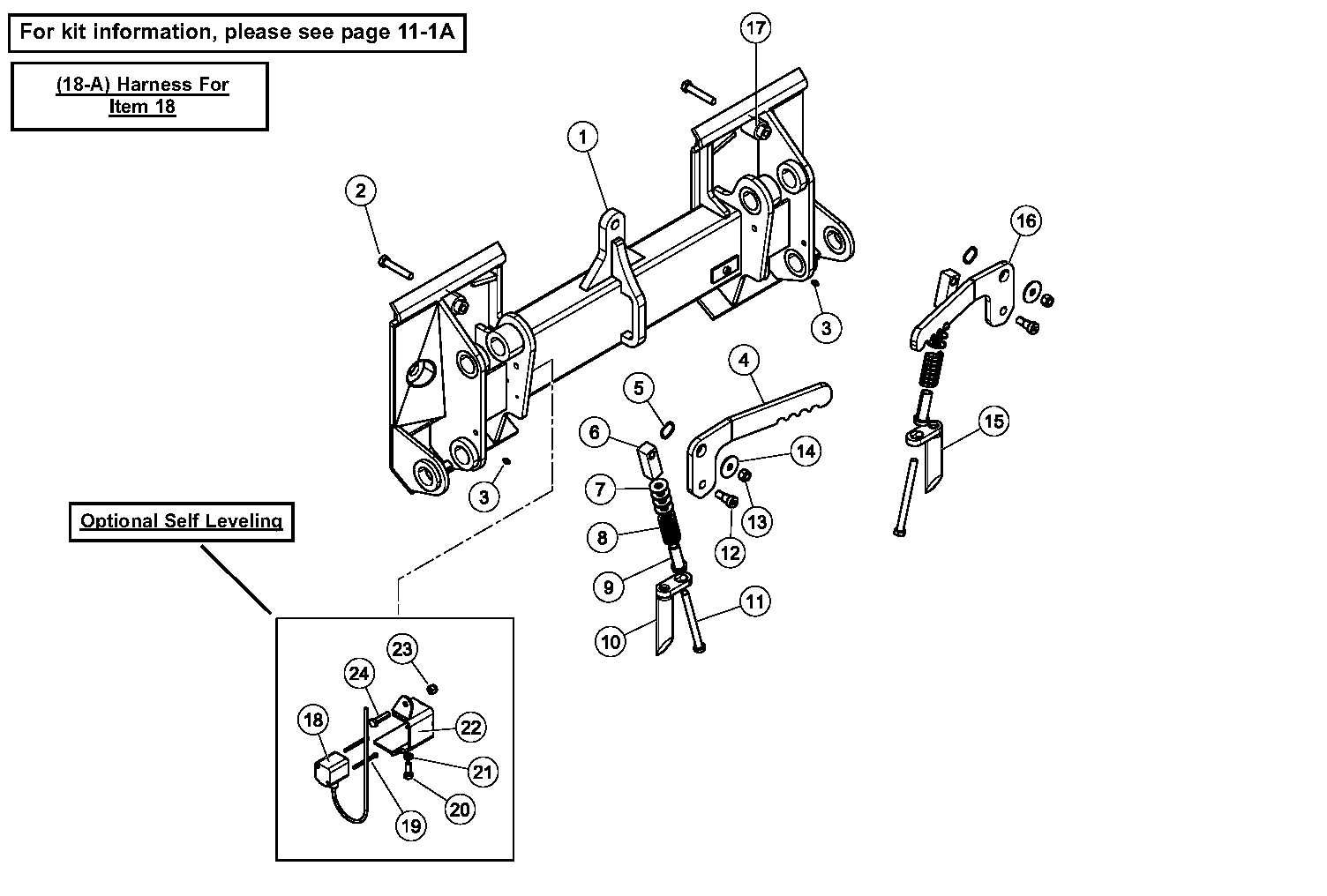

Having a comprehensive layout of a machine’s mechanical structure is essential for anyone involved in its maintenance and repair. This visual guide provides crucial insight into how each component is positioned and functions within the overall system. A clear understanding of this arrangement helps professionals and operators easily identify parts and their interconnections, making both maintenance and troubleshooting more efficient.

Importance of Accurate Component Placement

Proper placement of each component is vital for ensuring that the equipment operates smoothly. Incorrectly installed or misaligned elements can lead to decreased performance, increased wear, or even failure. By following a detailed representation, users can ensure every piece is correctly positioned, minimizing potential issues in the long run.

Maximizing Efficiency Through Knowledge

Being familiar with the internal setup allows technicians to act swiftly when addressing malfunctions. It also improves decision-making when it comes to replacements or upgrades. With a clear layout, operators gain a deeper understanding of the machinery’s needs, leading to better preventive care and fewer breakdowns.

Essential Components of the T190 Model

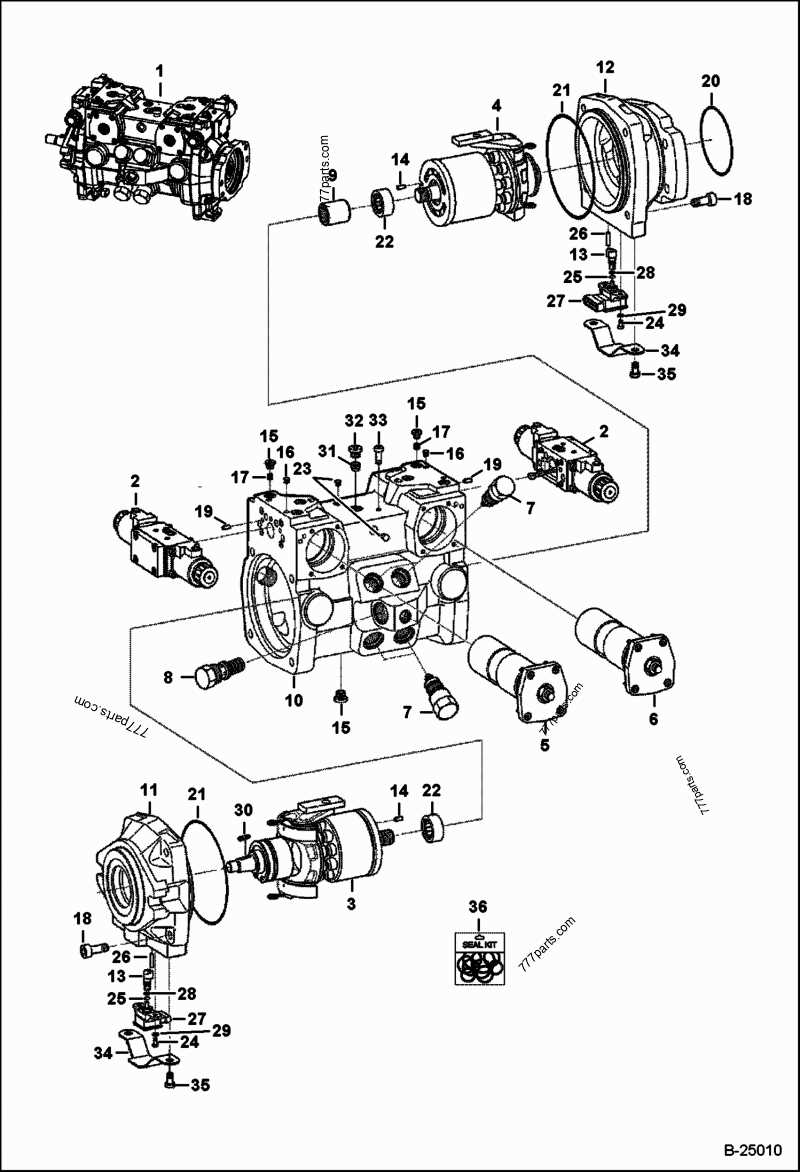

Every piece of heavy machinery consists of key elements that work together to ensure optimal performance. These essential components form the backbone of the system, each with its specific function that supports the overall operation. Understanding these fundamental parts is crucial for both operators and technicians, as it allows them to better manage maintenance tasks and identify issues quickly.

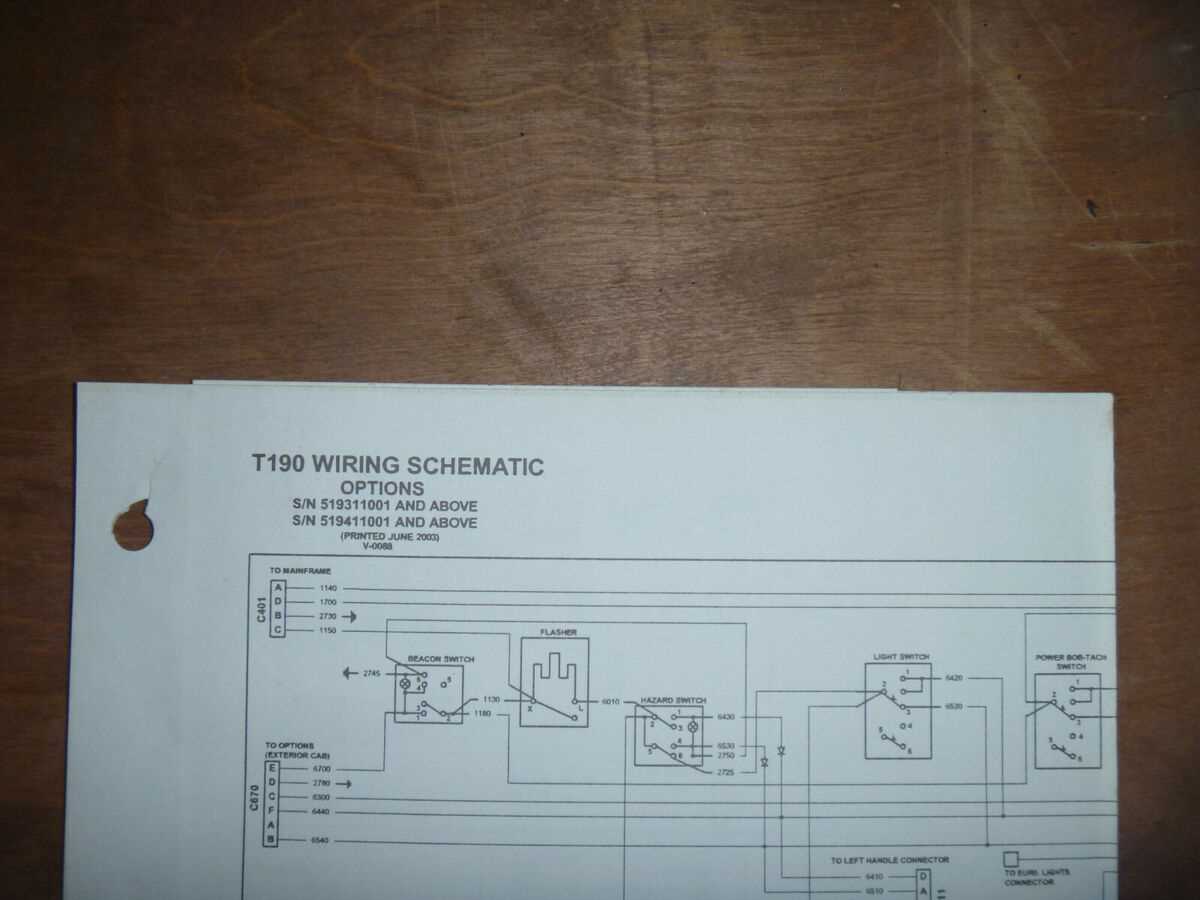

Among the most critical elements are the engine, hydraulic system, and drive mechanisms. The engine serves as the power source, while the hydraulic system controls movement and lifting. The drive components are responsible for ensuring that the machinery moves effectively, providing necessary traction and stability. Each of these elements must be in peak condition to maintain the machine’s reliability and efficiency.

How to Use the Parts Diagram Effectively

Having a detailed visual representation of the machine’s internal structure is invaluable for anyone working on its maintenance or repair. It helps users to identify each component and understand its specific role within the overall system. Effectively using this guide can greatly improve the accuracy of repairs, streamline maintenance tasks, and reduce the likelihood of errors.

To use the visual guide efficiently, start by familiarizing yourself with the layout and understanding how each part fits into the larger system. Pay close attention to the labeling and arrangement of each component, as this will help you quickly locate the relevant areas when performing repairs. This method is particularly useful when dealing with complex issues or when replacing damaged elements.

Additionally, ensure that you cross-reference the diagram with manufacturer manuals to verify the part numbers and specifications. This approach minimizes the risk of using incorrect replacements, which could negatively impact the performance and longevity of the machine.