Understanding the intricate details of outdoor machinery is essential for maintaining their performance and longevity. By studying the layout and structure of various elements, owners can easily identify parts that require attention or replacement. This knowledge is not only useful for troubleshooting issues but also helps in performing routine maintenance efficiently.

Each tool comes with its own set of components, and knowing where each part fits and how it functions makes a significant difference in operation. Whether it’s the engine, drive system, or safety features, gaining familiarity with these individual sections can save time and reduce the likelihood of mishaps.

By familiarizing yourself with these crucial pieces, you’ll be better equipped to diagnose problems and ensure your machine operates at peak performance. Understanding how to properly assemble or disassemble the parts also offers a clear path toward effective repairs and upgrades, contributing to overall reliability and durability.

Understanding the Components of Your Lawn Equipment

Each piece of lawn machinery consists of several critical elements that work together to ensure smooth and efficient operation. Familiarity with these components is crucial for identifying issues and performing effective maintenance. Whether you’re handling a mower or any other outdoor tool, knowing how the system is organized can help you spot potential problems early and address them before they escalate.

Commonly, these machines include several key systems, each with a distinct function. The overall performance relies on the interaction of these parts, so understanding their roles can aid in troubleshooting and repairs. Below are the primary sections that make up most lawn equipment:

- Engine Assembly: Powers the entire system, providing the necessary force for operation.

- Drive System: Transfers power from the engine to the wheels or blades, allowing movement and cutting.

- Control Mechanisms: Includes levers, handles, and switches that allow the user to interact with the machine and adjust its settings.

- Safety Features: Essential components designed to protect the operator from accidents, including emergency stop systems and protective guards.

- Fuel and Exhaust Systems: Responsible for the intake of fuel, combustion, and the expulsion of exhaust gases during operation.

By understanding how each of these systems works, you can better assess the condition of your equipment and perform maintenance tasks more efficiently. Moreover, if you know the location and function of these essential parts, you’ll be in a better position to handle repairs or replacements when needed.

Key Parts for Efficient Equipment Functionality

For outdoor machines to function optimally, each system relies on specific elements that need to operate in harmony. Understanding these key components helps ensure that everything runs smoothly, from the engine to the cutting mechanism. Identifying and maintaining these critical parts is essential for keeping the machine in top condition and avoiding unnecessary repairs.

Engine and Power System

The engine is the heart of any mechanical tool. It generates the force required to power the other systems and drive the machine forward. A well-maintained engine ensures reliable performance and longevity. Regular checks on fuel lines, spark plugs, and air filters can prevent power loss and inefficiency. Proper care of these elements can also extend the engine’s lifespan and ensure it runs at peak efficiency.

Drive Mechanism and Cutting System

The drive system and cutting mechanism are equally important. These systems are responsible for transferring energy from the engine to the wheels or blades. A malfunctioning drive system can hinder movement, while issues with the cutting system can lead to uneven results. Regular inspection and lubrication of gears, belts, and pulleys help maintain smooth operation, reducing wear and tear.

Maintaining these key systems ensures not only performance but also safety, as they prevent breakdowns and improve the overall efficiency of the equipment. Proper upkeep of these components helps avoid costly repairs in the future.

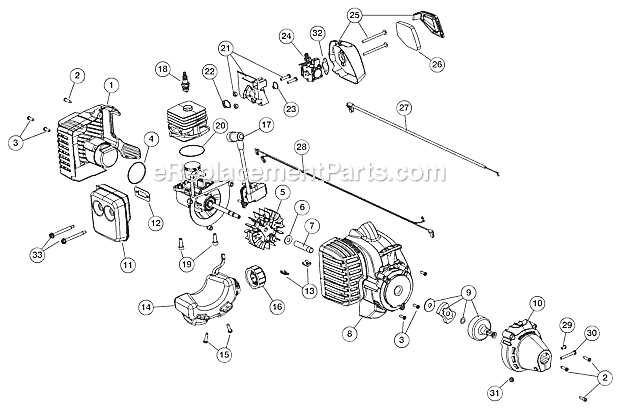

How to Read the Equipment Layout

Understanding how to interpret the layout of a machine is essential for anyone looking to troubleshoot or maintain their equipment effectively. These visual guides offer a clear representation of how the different elements are arranged, providing insight into their functions and connections. By becoming familiar with these schematics, you can quickly identify where each part fits and how they interact with one another.

Typically, these diagrams are organized to show a detailed view of the main sections, from the engine to the drive system, highlighting individual components and their placements. Each part is usually marked with a label or a number, which corresponds to a specific description in the manual or parts list.

To effectively read these diagrams, it’s important to focus on the following:

- Identifying Labels: Each component is usually labeled with a number or code that helps locate it in the reference guide.

- Understanding Connections: Look at how different parts are linked, whether through bolts, gears, or wires, as this will help you understand the flow of energy or motion.

- Color Codes or Symbols: Some diagrams use color or symbols to distinguish different systems (such as electrical, mechanical, or fuel-related parts).

With practice, these visual tools become incredibly useful, enabling you to spot issues, plan repairs, and order replacements with confidence. Knowing how to read the equipment layout is an invaluable skill for any operator or technician.