Understanding the structure and essential elements of complex machinery is crucial for efficient operation and longevity. Knowing the layout and function of each component ensures proper upkeep and helps avoid costly repairs.

When working with construction equipment, having a clear overview of all key parts aids in identifying wear and tear or malfunctioning areas. This knowledge is vital for technicians and operators alike to perform maintenance tasks effectively and maintain peak performance.

Proper maintenance relies heavily on understanding the intricate relationships between different sections of the machine. Regular inspection and part replacement keep the system running smoothly, minimizing downtime and maximizing productivity.

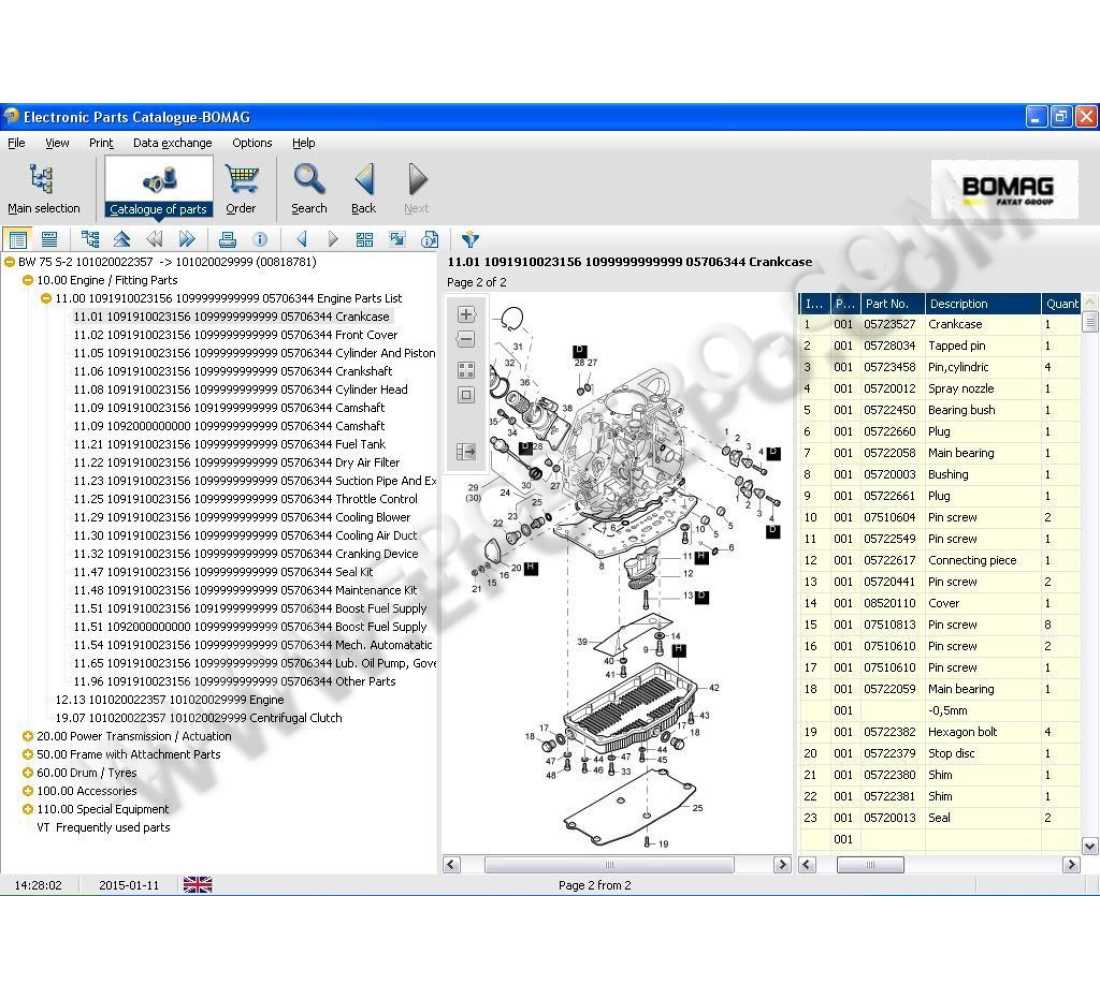

Understanding Machine Layout and Component Arrangement

Efficient operation of any heavy machinery depends on the proper understanding of its internal structure. Every machine consists of various interconnected elements, each with a specific role to play in ensuring smooth functionality. Familiarity with these key sections allows users to recognize potential issues early and act accordingly.

The layout typically divides the equipment into primary functional zones, each housing critical components that contribute to the overall performance. Recognizing how each part interacts within the system helps in diagnosing problems quickly and choosing the correct maintenance approach.

Clear identification of the arrangement is essential for anyone involved in the upkeep or repair process. By understanding the positioning and function of different sections, it becomes easier to ensure longevity and prevent unexpected breakdowns during operation.

How to Identify Key Machine Components

Recognizing the individual elements of a machine is essential for proper operation and timely maintenance. Each component is designed for a specific function, and knowing how to identify them can prevent performance issues and ensure smooth operation.

Start by familiarizing yourself with the overall structure of the equipment. Key components are often marked with unique identifiers or serial numbers that help differentiate them. Pay close attention to labels, model-specific markings, and component shapes to easily locate the most important parts.

Once you understand the layout, begin by identifying larger, more obvious elements such as the engine, hydraulic systems, and control mechanisms. Smaller components often relate to these core systems, and understanding their placement will simplify maintenance and troubleshooting.

Essential Components for Machine Maintenance

Proper maintenance requires understanding which parts need regular attention to ensure optimal performance. Some components bear more strain during operations and thus require frequent inspection and replacement. Regular checks on these key sections help prevent breakdowns and extend the life of the equipment.

Critical Systems to Inspect Regularly

The engine and transmission systems are at the core of any heavy-duty machinery, often requiring the most care. These systems must be serviced regularly to avoid issues with power output and fluid circulation. Checking oil levels, filters, and seals helps maintain smooth operation and prevents wear over time.

Hydraulic and Control Mechanisms

Hydraulic components and control systems also play a pivotal role in equipment efficiency. Regularly inspecting hoses, pumps, and valves ensures proper fluid flow and pressure, preventing malfunctions. This part of the machine is vital for maintaining stability and precision during heavy tasks.