Every heavy-duty vehicle designed for winter maintenance is equipped with various mechanisms to ensure it performs efficiently. Understanding the structure and functionality of these components is essential for optimal operation and longevity. Whether you’re a professional or a DIY enthusiast, knowing how to identify and maintain each piece will save time and prevent costly repairs.

Proper knowledge of each element can make a significant difference in the effectiveness of your machine. When you are familiar with the layout and connections of these mechanisms, you can easily detect any issues and address them promptly. It also helps when ordering replacements or upgrades, ensuring you get the right components for your specific model.

In this guide, we will explore the key sections of your equipment, highlighting essential parts and offering insights into their roles. Whether you need to perform maintenance or simply gain a deeper understanding, this information will provide a valuable foundation for effective care and management.

Understanding Equipment Components

Effective operation of winter maintenance machinery relies on the seamless interaction of various parts, each playing a crucial role in ensuring functionality. The complexity of these machines requires a thorough understanding of how different components work together to deliver optimal performance in harsh conditions. By breaking down the major elements, you can gain insights into their individual functions and how they contribute to the overall efficiency of the vehicle.

Each critical component has a specific task, whether it’s powering the vehicle, controlling the movement of the system, or enabling the precise positioning of essential tools. Recognizing these parts and their interconnections not only helps in troubleshooting but also assists with routine maintenance and repairs. Familiarity with how these elements operate will make diagnosing issues much simpler and more efficient, ultimately extending the lifespan of your machinery.

How to Identify Essential Components

Identifying the key elements of your winter maintenance equipment is an important step in ensuring its proper functionality. Each part has distinct features that allow you to recognize its purpose and role in the system. Understanding these components will help you manage repairs, replacements, and routine checks more efficiently. With the right knowledge, you can quickly identify any issues that arise and address them before they cause larger problems.

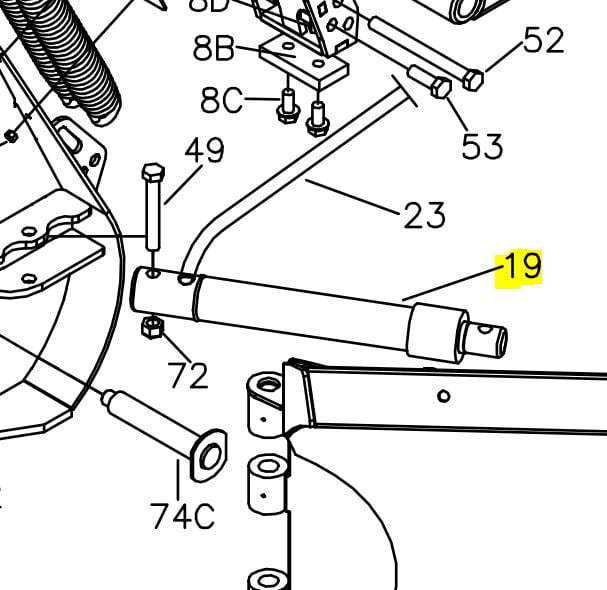

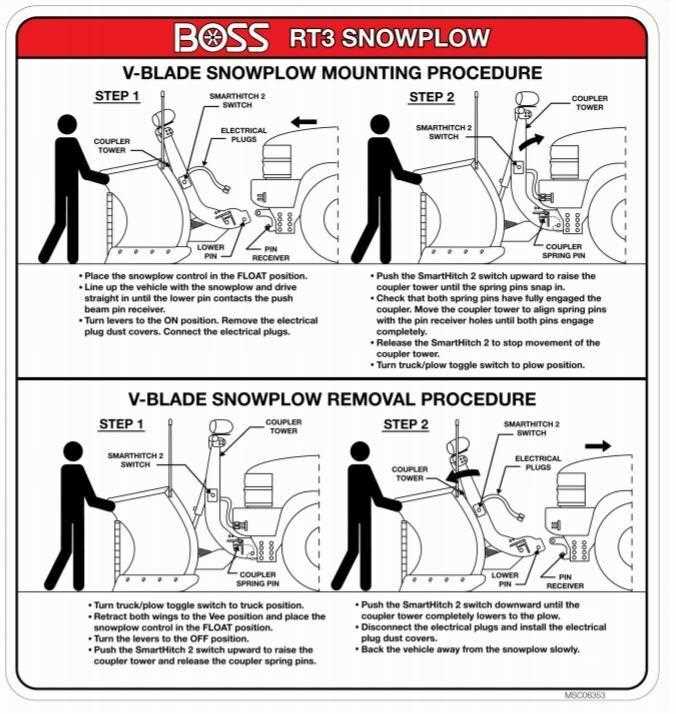

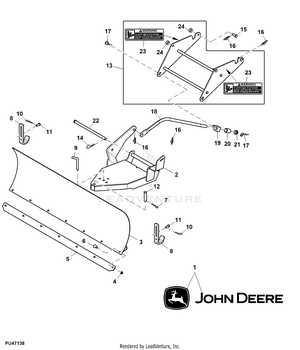

Start by familiarizing yourself with the major sections of the equipment. Focus on the control mechanisms, support structures, and any attachments that are crucial for the operation. Pay attention to the labeling, part numbers, and physical characteristics of each component. This knowledge allows you to distinguish between different types of elements and ensures that you can find the correct replacements when necessary.

Maintaining Your Equipment System

Regular maintenance of your machinery ensures its reliability and prolongs its operational life. By understanding the importance of each component and how it interacts with others, you can perform routine checks to keep everything in top working condition. Proper care helps prevent unexpected failures and keeps the system running smoothly through every season.

Routine Checks and Adjustments

Frequent inspections are essential for detecting wear and tear on critical components. Check the movement mechanisms, hydraulic systems, and any attachments to ensure they are functioning properly. Tighten any loose bolts or connectors and replace parts that show signs of significant damage. Routine maintenance is key to preventing costly breakdowns.

Cleaning and Lubrication

Cleaning your equipment after each use and applying appropriate lubricants to moving parts helps maintain smooth operation. Ensure that all moving components are well-lubricated to reduce friction and prevent premature wear. Regular cleaning removes debris and grime, which can cause damage if left unchecked. Proper lubrication and cleaning contribute to the overall performance and longevity of your system.