Understanding the inner workings of your tool can significantly extend its lifespan and improve its performance. By familiarizing yourself with its key components, you’ll be able to identify any issues and carry out basic repairs. This guide offers a comprehensive look at the essential parts that make up your device, providing insights into how they function together to ensure smooth operation.

Proper maintenance and timely repairs are vital to keep your equipment functioning at its best. In the following sections, we’ll cover how to recognize and troubleshoot common issues, as well as offer step-by-step instructions on how to replace or fix worn-out pieces. With a little knowledge, you can save time and money while ensuring your tool remains in top condition.

Understanding Bostitch Stapler Components

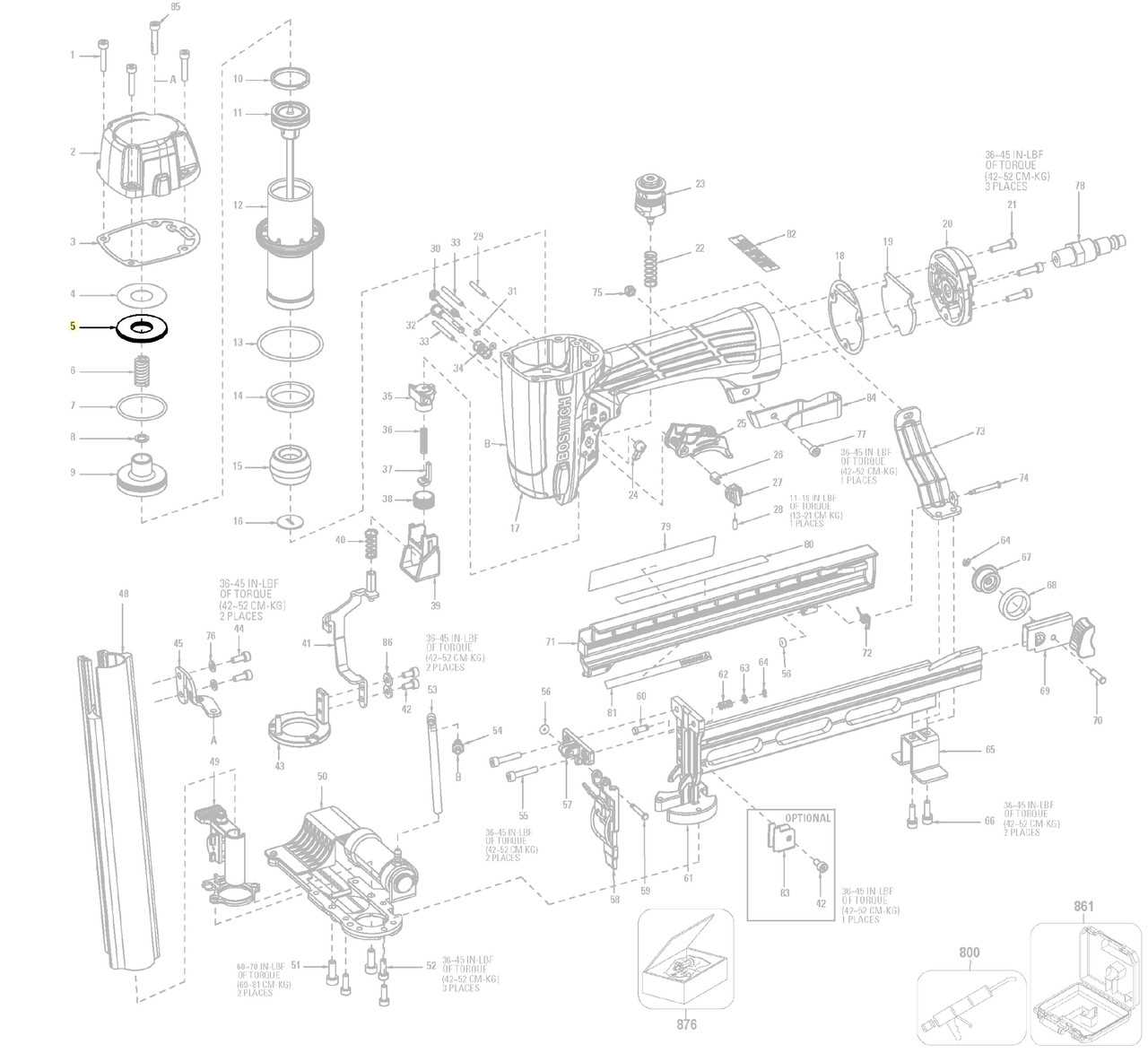

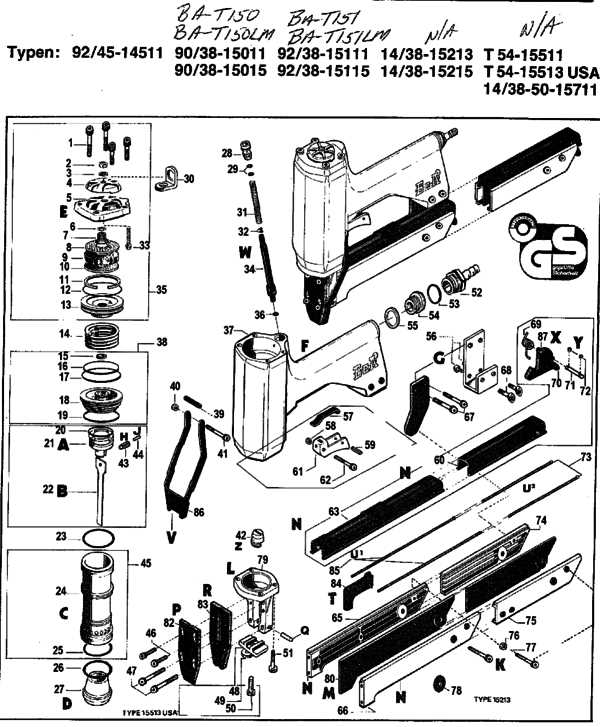

To maintain or repair your tool effectively, it’s essential to grasp the function of each element inside. Each piece plays a crucial role in how the device operates, ensuring smooth and consistent performance. By understanding these elements, you can easily identify potential issues and address them promptly.

Key components, such as the feed mechanism, spring tension, and the main driving system, work together to enable efficient use. Familiarizing yourself with these elements not only helps with troubleshooting but also assists in making informed decisions when a replacement or fix is needed.

Knowing how each part interacts allows for a deeper understanding of the overall functionality. This knowledge can make the repair process much simpler, enabling you to extend the lifespan of your tool and keep it working like new for longer.

How to Identify Stapler Parts

Recognizing the components within your tool is the first step in any repair or maintenance process. Each piece has a distinct function that contributes to the overall operation of the device. By learning how to identify these elements, you can ensure that any necessary fixes or replacements are done correctly.

Common Elements in Your Device

Most devices include a few basic components such as a loading chamber, a pressure mechanism, and a control lever. Understanding the role of each allows for quicker troubleshooting and ensures the right piece is replaced when needed. Pay close attention to the shape, size, and positioning of each element for accurate identification.

How to Spot Worn or Broken Components

When identifying a malfunction, it’s essential to check for visible wear or damage. Look for components that are cracked, bent, or misaligned. Some elements, like springs or levers, may wear out faster due to frequent use. Identifying these issues early on can prevent further damage and ensure the tool remains operational.

Common Repairs for Bostitch Staplers

Frequent use of your tool may eventually lead to certain issues that affect its functionality. Many of these problems can be resolved through simple repairs, restoring your equipment to working condition without the need for professional help. By identifying common malfunctions and addressing them quickly, you can extend the life of your device and avoid costly replacements.

Fixing Jams and Misfeeds

One of the most common issues is a jam or misfeed, which occurs when material becomes stuck in the loading area or feeding mechanism. This can be caused by a variety of factors such as incorrect alignment or a worn-out component. Carefully inspecting the area and removing any blockages will usually resolve this problem. Additionally, ensuring the proper alignment of the device can prevent further issues.

Replacing Worn Springs or Levers

Another common repair involves the replacement of springs or levers that control the movement of the mechanism. Over time, these parts may lose tension or become damaged, affecting the overall performance. Replacing these worn-out pieces is relatively simple and can significantly improve the tool’s efficiency.