When working with heavy-duty machinery, knowing the different components that make up the tool is essential for proper operation and maintenance. A clear understanding of how each piece functions helps ensure optimal performance and longevity. This knowledge becomes especially important when repairs or replacements are needed, as it allows you to identify specific areas that require attention.

The structure of the machinery consists of several key elements, each serving a unique purpose. From the framework that supports the system to the individual components responsible for various tasks, recognizing their roles helps in troubleshooting and adjustments. Having a detailed reference for these parts can significantly reduce the time spent diagnosing issues.

By familiarizing yourself with the different sections of the equipment, you can confidently perform routine maintenance or even more advanced repairs. Whether you are a beginner or a seasoned operator, knowing what each part does will enhance your ability to keep the machinery in top condition and maximize its efficiency.

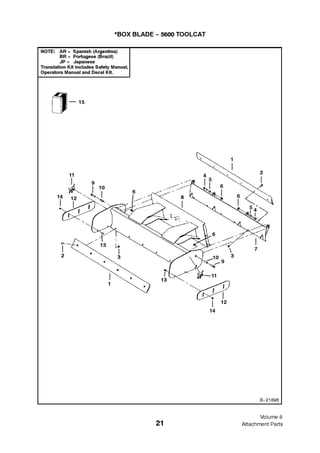

Understanding Box Blade Components

Heavy-duty equipment designed for land leveling and grading relies on several crucial elements that work together to achieve precise results. Each section of the tool is engineered to perform a specific task, contributing to the overall efficiency of the machine. Understanding these individual components helps operators maintain and repair the machinery effectively, ensuring long-term reliability and performance.

The main structure of the equipment is built for durability and stability, supporting the various parts that interact with the ground and perform heavy tasks. From the components that control depth to those that manage the distribution of materials, each plays an integral role in achieving the desired outcome. Recognizing these roles is essential when making adjustments or diagnosing issues.

By becoming familiar with the different elements and their functions, operators can perform routine checks and repairs with confidence. This knowledge not only reduces downtime but also helps prevent costly mistakes during operation. Proper understanding allows for better care and extends the lifespan of the machine, ensuring it continues to perform at its best over time.

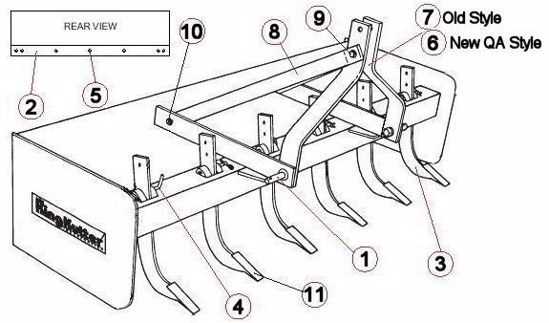

Key Parts of a Box Blade

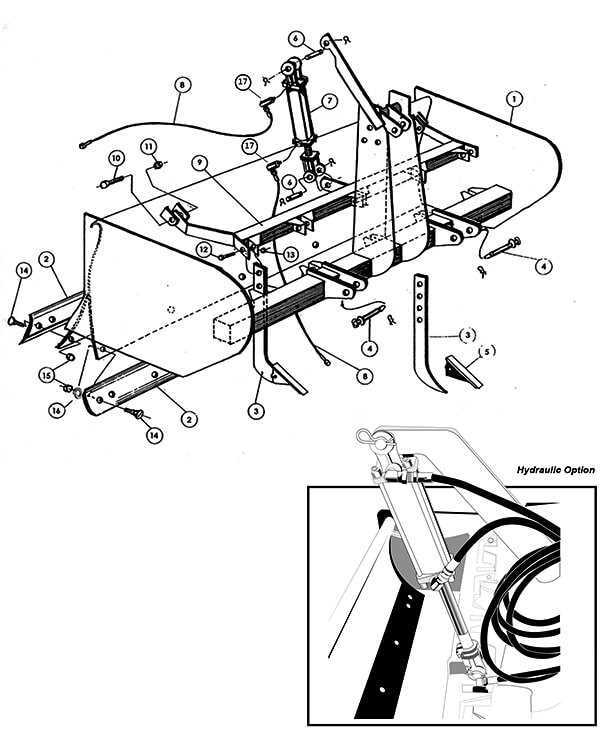

Every machine designed for land leveling and soil manipulation is made up of several essential components, each contributing to its overall function. These sections work in harmony to ensure smooth operation and effective performance, allowing operators to achieve precise results in tasks like grading and clearing. Understanding the function of each element is critical for maintenance and repair, as well as for making necessary adjustments during use.

At the core of the system, the main frame provides the structural support for the entire machine, holding all other elements securely in place. Attached to this frame, the cutting tools and scraping mechanisms are responsible for moving and reshaping soil, while the depth control elements allow the operator to set the required level for the job at hand. Additionally, the rear sections play a role in smoothing and distributing the materials evenly across the surface.

Each of these critical components serves a unique purpose, working together to optimize the machine’s efficiency. Identifying them and understanding how they interact ensures that operators can perform troubleshooting, adjust settings, and complete repairs as needed. Proper care and attention to these parts help maintain the equipment in peak condition, reducing downtime and maximizing productivity.

How to Identify Box Blade Features

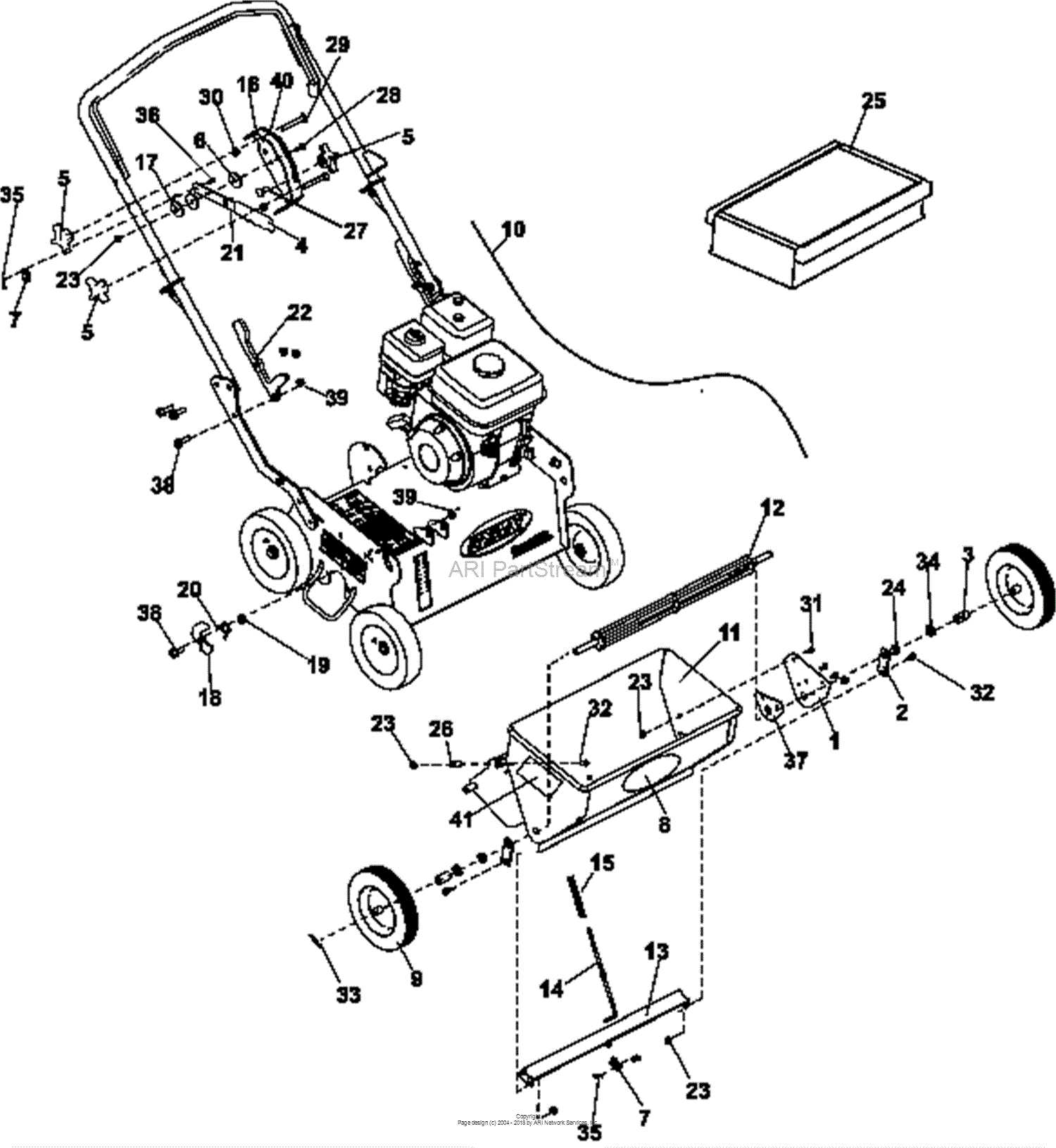

Recognizing the distinct features of heavy-duty machinery is key to understanding its operation and ensuring optimal performance. By identifying the components that contribute to the overall function, operators can better manage the equipment, make informed decisions, and troubleshoot issues more effectively. Familiarity with the tool’s layout is essential for routine checks and timely repairs.

Visual Inspection of Key Elements

Start by visually inspecting the overall structure of the machine. The main frame supports various sections, while the cutting edges and scraping tools are typically located at the front, designed to interact with the ground. These components are usually made from durable materials to withstand heavy impact. Understanding the position and purpose of each part will help you determine the tool’s capabilities and limitations.

Recognizing Functional Features

Next, focus on the functional aspects, such as depth control mechanisms, which allow you to adjust how deeply the tool penetrates the ground. Other adjustable sections, such as leveling arms and side components, assist in managing the distribution of soil or debris. These features can often be identified by their adjustable mechanisms or hydraulic controls that influence performance during use.