When working with complex machinery, it’s essential to have a clear understanding of how the individual components fit together. Knowing the exact layout of every element allows for proper assembly, troubleshooting, and efficient maintenance. This section provides an in-depth look at the various elements that make up a system, helping users navigate through their repairs and improvements with ease.

By studying the component arrangements, one can quickly identify how each part contributes to the overall performance. This knowledge not only aids in the proper functioning of the machine but also ensures that any necessary replacements or adjustments can be made with precision. Familiarizing oneself with these structures is crucial for both novice users and experienced professionals.

Accurate identification of every piece is key to successful management, whether you’re assembling a new setup or performing a detailed fix. Properly interpreting these connections empowers users to make informed decisions during maintenance and repairs. With the right guidance, the process becomes straightforward and effective.

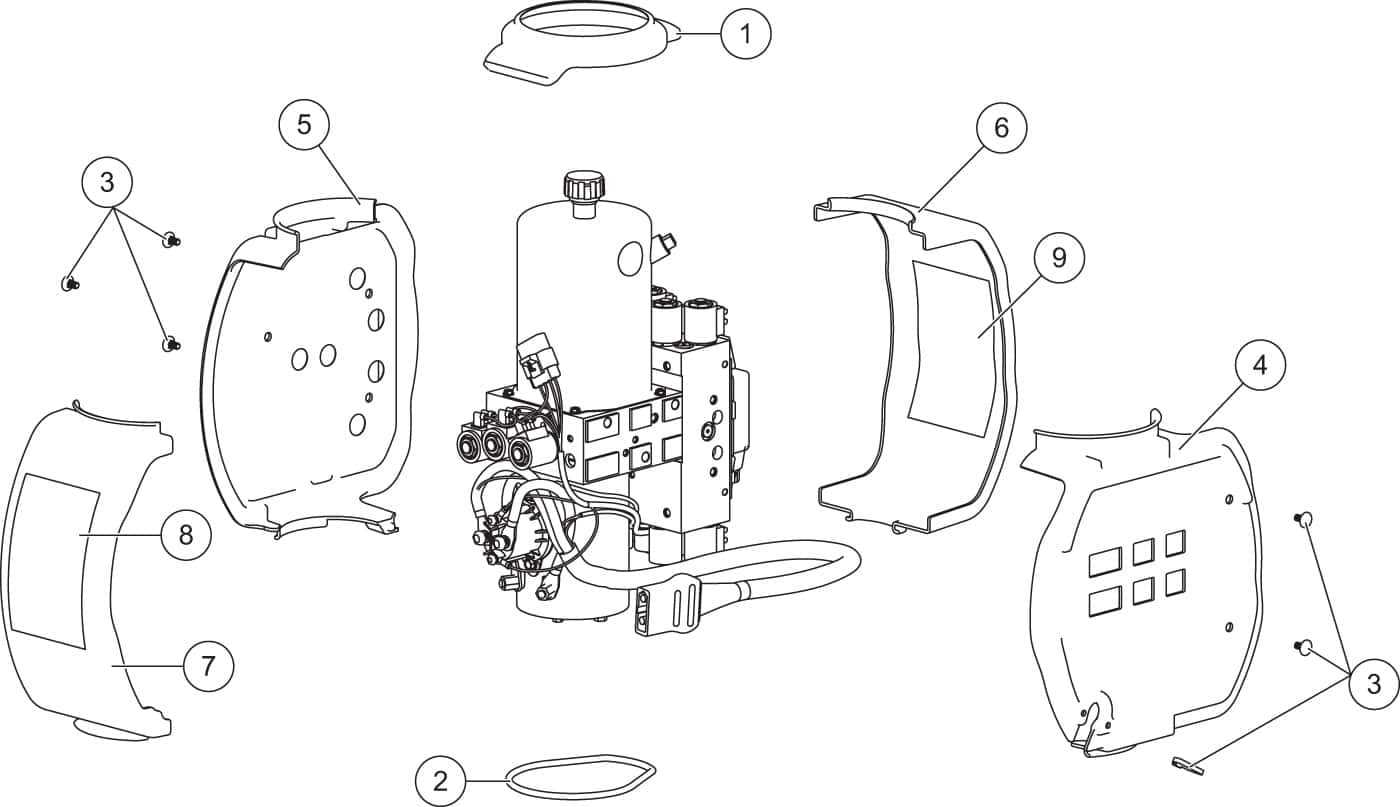

Understanding the Br600 Parts Diagram

To effectively manage and repair complex machinery, it’s essential to familiarize yourself with the detailed layout of its components. Each element within the system has a unique role, and understanding how they interact can significantly improve troubleshooting and maintenance efforts. This section breaks down the key features of the layout, offering clear insights into each component’s function and relationship.

When approaching the system’s configuration, it is important to recognize the arrangement of major elements, their connections, and how they influence overall performance. By mapping out these connections, users gain the ability to quickly locate issues, determine the need for replacements, and identify necessary adjustments. Familiarity with this structure is invaluable for efficient repair and system optimization.

For optimal use, users should focus on identifying each key part and understanding its specific contribution to the machine’s operation. A comprehensive understanding of these connections ensures that any maintenance tasks, whether simple repairs or more intricate adjustments, are handled with precision and ease.

Key Components and Their Functions

Understanding the core elements of a system and their specific roles is crucial for effective operation and maintenance. Each part plays a vital function, contributing to the overall performance and efficiency. In this section, we will explore the essential components and explain how they interact within the system to ensure smooth functionality.

Engine and Power Mechanism

The engine is at the heart of the operation, driving the entire system. It converts energy into motion, providing the necessary power for various functions. This component is responsible for generating the force needed for the system to perform its tasks, and its proper maintenance is critical for optimal operation.

Control System and Sensors

The control system is responsible for managing the flow of information and ensuring all components work in harmony. It relies on sensors to monitor conditions and adjust performance. These sensors detect variables like pressure, temperature, and speed, allowing the system to adapt in real-time for improved efficiency and safety.

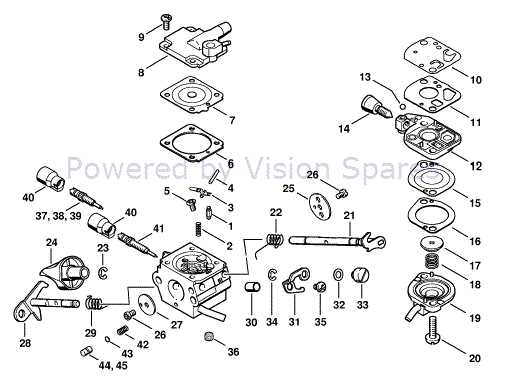

How to Read the Br600 Diagram

Being able to read and interpret technical layouts is a critical skill for anyone working with complex machinery. These layouts provide a detailed visual representation of how each component is positioned and connected, helping users understand the system’s structure. This section will guide you through the process of analyzing these schematics, allowing you to effectively identify components and their interconnections.

Understanding the Symbols and Labels

In technical schematics, symbols and labels are used to represent different components and their functions. Each symbol is standardized, making it easy to identify the part it represents, whether it’s a mechanical element or an electrical connection. It’s important to familiarize yourself with these symbols to quickly locate the parts you need to address.

Interpreting the Connections and Flow

The layout also illustrates how components are interconnected, showing the flow of power, signals, or materials. By tracing these connections, you can understand how the system operates as a whole. Pay close attention to the lines and arrows, as they indicate the direction of flow and the relationship between parts. This will help you identify where adjustments or repairs may be needed.

Identifying Critical Parts and Labels

To effectively manage and repair any system, it’s crucial to recognize the most important components and their associated labels. These elements play pivotal roles in the operation and troubleshooting of the machine. In this section, we will explore how to identify key elements and understand the labels that define them within the layout.

Recognizing Key Components

Key components are often marked in a schematic to indicate their importance and functionality. These elements are central to the system’s operation, and understanding their placement helps in recognizing potential issues. By identifying these critical components, you can quickly pinpoint areas that may require attention or replacement during maintenance.

Understanding Labeling Conventions

Labels are used to provide additional information about each component, such as part numbers, specifications, and function. These markings are vital for accurate identification and ensure that the correct replacement parts are used. It’s essential to familiarize yourself with the labeling conventions used in the schematic, as they guide you in making the right decisions during repairs or upgrades.

Maintenance and Repair Tips

Proper upkeep and timely repairs are essential for ensuring long-term functionality and efficiency of any system. By following a few simple maintenance practices, you can extend the lifespan of your equipment and avoid costly breakdowns. This section covers key tips for maintaining and repairing your machinery, helping you keep it running smoothly.

- Regular Cleaning: Dirt and debris can build up over time, affecting the performance of critical components. Regularly clean the machine to prevent blockages and ensure proper airflow.

- Inspect for Wear and Tear: Regularly check for signs of wear or damage, particularly on moving parts. Replace any worn-out components before they fail to avoid more extensive damage.

- Lubrication: Keeping moving parts properly lubricated reduces friction and prevents premature wear. Make sure to apply the recommended lubricant to joints, bearings, and other parts that require movement.

- Check Electrical Connections: Loose or corroded connections can disrupt the system’s operation. Inspect all electrical connections and clean or tighten them as necessary.

- Monitor Performance: Keep track of the system’s performance over time. If you notice any unusual sounds, vibrations, or inefficiencies, address them immediately to prevent further damage.

By following these tips, you can keep your equipment in peak condition and prevent unexpected failures. Regular maintenance not only saves time and money but also ensures that your machinery operates safely and efficiently.