When it comes to the proper functioning of mobility platforms, knowing the individual components is essential for effective maintenance and repairs. Understanding how each element interacts can ensure smooth operation and extend the lifespan of the system.

Identifying the key features within the system allows users and technicians to pinpoint issues quickly. A thorough comprehension of the setup aids in making informed decisions about upgrades or necessary fixes.

Proper care and regular inspection of these elements play a crucial role in preventing malfunctions. Taking proactive steps in identifying worn-out components or potential hazards can save time and reduce long-term costs.

Key Components of Mobility Systems

Every mobility platform consists of several crucial elements that work together to ensure safe and reliable operation. Understanding these components helps users and technicians maintain the system’s functionality and efficiency over time. By identifying the main features, individuals can take appropriate steps for regular upkeep and address potential issues before they become serious concerns.

Structural Framework

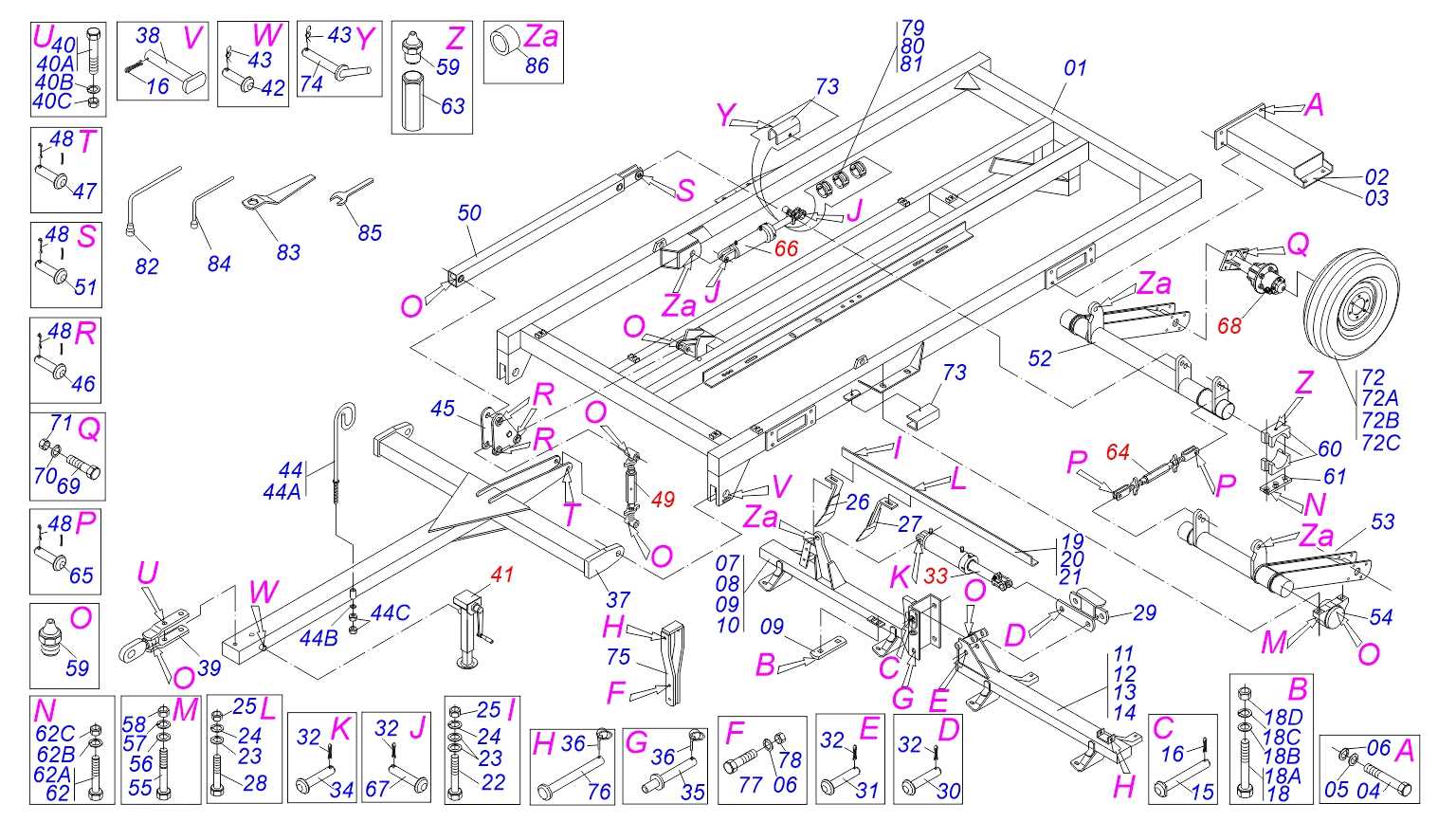

The structural framework serves as the backbone of the system, providing stability and support for all other components. This strong, durable base is designed to bear the weight of the user and withstand the mechanical stresses involved during operation. It ensures that all other elements are properly aligned and function smoothly.

Mechanical and Electrical Components

Mechanical components, such as gears, motors, and actuators, are responsible for the movement and functionality of the system. These parts interact with electrical components like controllers and wiring, which transmit signals and power to operate the mobility platform. Regular inspection of these elements is essential to prevent malfunctions and ensure smooth performance.

Identifying Components in Mobility Systems

Understanding the various elements within a mobility system is essential for effective troubleshooting and maintenance. Recognizing these components allows users to identify issues quickly and perform necessary repairs or replacements. With proper knowledge of each feature, both technicians and users can ensure the system operates at its best.

Electrical and Mechanical Elements

The core of any mobility system lies in its electrical and mechanical components. The motor, control board, and wiring are responsible for powering and directing the platform’s movement. Identifying these parts is crucial to troubleshooting operational problems, as any issues with these elements could lead to system malfunctions.

Support and Structural Components

In addition to functional parts, the structural components offer vital support and stability. These include platforms, supports, and frames that provide the physical foundation for the system. Inspecting these parts regularly ensures that the system remains secure and able to bear weight safely during operation.

Maintaining Your Mobility Platform for Longevity

Regular maintenance is essential to extend the lifespan of any mobility system. By performing routine inspections and addressing minor issues promptly, users can prevent more significant problems and ensure the system operates smoothly over time. Taking proper care of the components not only enhances performance but also reduces the risk of costly repairs.

To keep the system in optimal condition, it is important to clean and lubricate moving parts regularly. Checking for wear and tear on the structural components can help identify potential weaknesses before they affect performance. Timely replacement of any damaged or worn-out elements is also crucial in maintaining the system’s functionality and reliability.