Maintaining and repairing small engines requires a clear understanding of their internal structure. Whether you’re handling routine upkeep or addressing specific malfunctions, knowing the key elements of an engine is essential. Each part plays a crucial role in ensuring smooth operation, and recognizing how they work together is vital for successful repairs.

Breaking down complex systems into smaller, more manageable parts makes it easier to troubleshoot and perform repairs. This knowledge helps avoid costly mistakes and ensures that your engine runs efficiently for longer periods. By focusing on the individual components, even those with minimal mechanical experience can effectively address common issues and extend the life of their equipment.

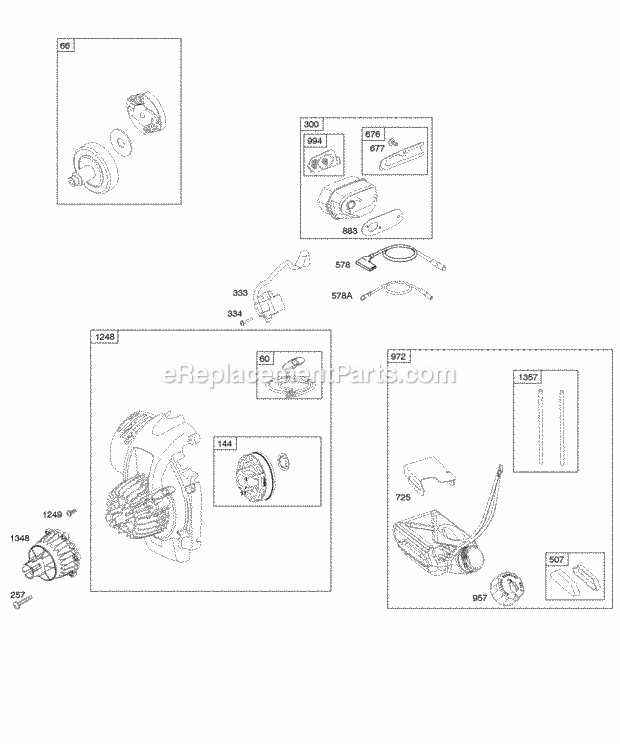

Once you’re familiar with the various sections of an engine, using a visual guide can further assist in identifying and replacing components. Such guides provide valuable insights into the engine’s build, making the repair process more straightforward and less time-consuming. A visual reference ensures that every part is in its correct position and highlights potential areas for improvement or attention.

Understanding the Engine Components

In order to maintain optimal performance, it’s crucial to have a solid understanding of how a small engine functions. These machines rely on a series of interconnected components, each contributing to the overall efficiency and power output. By learning about these elements, owners can troubleshoot effectively, perform repairs, and make informed decisions about necessary replacements or upgrades.

The internal workings of the engine involve various parts such as the fuel system, ignition system, and mechanical components that work together to produce power. Each element has a specific role, whether it’s to fuel combustion, control engine speed, or regulate air intake. Recognizing how these components interact ensures that the engine performs reliably under different conditions.

Maintenance becomes more manageable once the structure and function of the engine are understood. With a basic understanding of how the components fit together and operate, owners can more easily spot issues before they become major problems. Regular inspection of key sections helps prevent breakdowns and keeps the engine running smoothly for years to come.

How to Read a Parts Diagram

Understanding technical drawings is essential when working with mechanical systems. These visual guides provide a clear representation of a machine’s structure, allowing users to identify specific components and understand their placement. By interpreting these visuals correctly, individuals can effectively carry out repairs, replacements, and maintenance tasks without confusion.

The first step in interpreting such a drawing is to familiarize yourself with the symbols and notations used. Each part is usually labeled with a reference number, and the accompanying legend or list will provide the exact name and details of each component. Understanding these numbers and symbols will help you connect the visual elements with the physical parts you may need to work with.

Another important aspect is recognizing the layout. The diagram often shows the engine or machine in a cutaway view, with each part positioned relative to others. This allows for a better understanding of how the system functions as a whole. With this knowledge, finding the specific components you need to repair or replace becomes a much simpler task.

Essential Components of the Engine

Understanding the key elements of an engine is crucial for ensuring its proper functioning. These components work in harmony to generate power and maintain smooth operation. Each part plays a vital role, whether it’s controlling airflow, supplying fuel, or managing electrical systems. By knowing what each part does, you can better troubleshoot issues and perform necessary maintenance.

One of the primary sections includes the fuel delivery system, which consists of the fuel tank, pump, and carburetor. This system is responsible for providing the engine with the right mixture of fuel and air. Another critical area is the ignition system, which includes the spark plug, coil, and flywheel. These parts are essential for starting the engine and ensuring reliable operation.

The mechanical components, such as the piston, crankshaft, and cylinder, are at the heart of the engine’s power generation. These parts work together to convert fuel energy into mechanical energy. Regular inspection of these components can help detect wear and prevent further damage, keeping the engine running efficiently for a longer period.