Understanding the inner workings of small engines can be essential for proper maintenance and repairs. A clear visual guide can help simplify the process of identifying each element and its specific role within the machine. This is especially important for users aiming to extend the lifespan and performance of their equipment.

By referencing a well-structured blueprint, users can quickly familiarize themselves with the layout of key components, ensuring they are better prepared for any necessary replacements or troubleshooting. With a proper understanding, managing repairs becomes less intimidating and more efficient.

Accurate identification of each part is critical for maintaining smooth operation, and knowing how everything fits together can save both time and money in the long run. Whether it’s for routine servicing or dealing with unexpected failures, a comprehensive guide serves as a valuable tool for any engine owner.

Understanding the Components of 31C707 Engine

To ensure optimal performance, it is essential to have a clear understanding of how an engine operates and the function of each internal element. Each part plays a vital role in the smooth running of the machine, from fuel intake to exhaust output. Recognizing the role of each component allows for better diagnostics and quicker identification of issues.

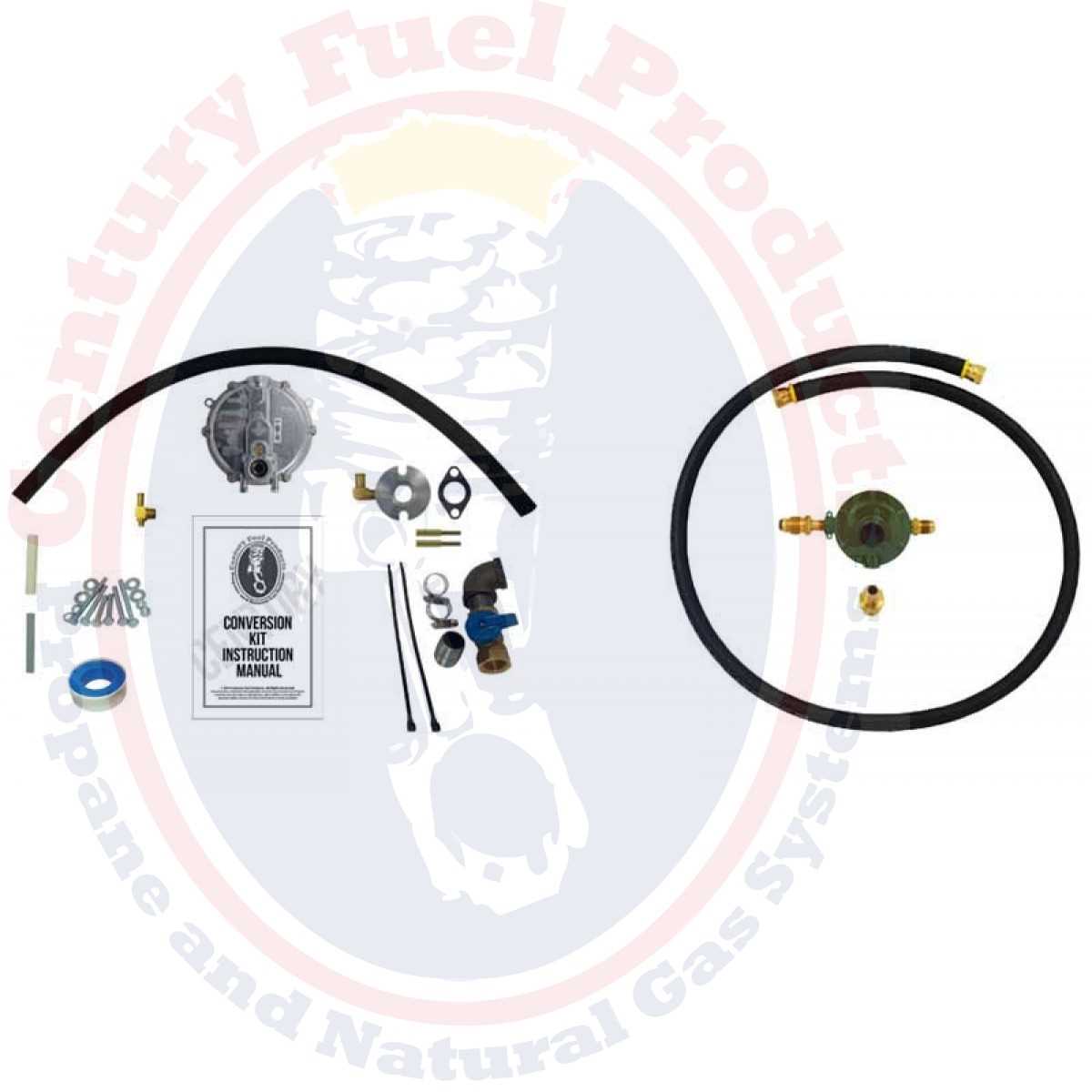

The core components typically include the fuel system, ignition, and power-generating sections, which work in harmony to produce the energy required for operation. The correct identification and management of these elements are crucial for effective maintenance, as improper handling can lead to further complications.

Regular inspection of individual parts is necessary to detect signs of wear or damage, which can impair overall performance. With an accurate understanding of the engine’s structure, troubleshooting becomes less challenging, allowing users to perform necessary repairs with confidence and accuracy.

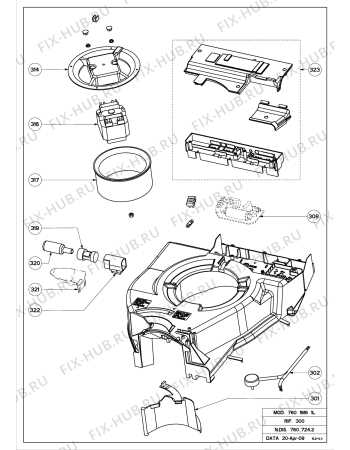

How to Read the Parts Diagram

Interpreting a technical layout of an engine’s components is a crucial skill for anyone involved in maintenance or repairs. A well-organized visual guide can break down complex machinery into simpler, more manageable sections, helping users understand the function of each element. Learning to read these illustrations will give you the tools to identify, troubleshoot, and replace faulty components more efficiently.

Focus on key sections first, such as the power unit, fuel delivery system, and ignition components. These are usually highlighted or marked with numbers or symbols to differentiate them from other parts. Carefully examine how each part connects with others to form the complete system, as this will help you recognize how the failure of one component might affect others.

Pay attention to part numbers, as they correspond to replacement items. These numbers provide a quick reference for ordering new components or verifying compatibility with other systems. Understanding these diagrams not only improves troubleshooting but also ensures you use the right tools and spare parts for any repairs.

Identifying Common Issues with the Engine

Engines, like any complex machine, can develop various issues over time. Identifying these problems early is essential to prevent further damage and maintain efficient operation. A systematic approach to diagnosing common faults can save time and money while ensuring that necessary repairs are done correctly.

Performance issues such as poor starting, stalling, or loss of power are often signs of underlying problems. These can stem from fuel delivery issues, ignition malfunctions, or clogged filters. Regularly checking key components like spark plugs, fuel lines, and air filters can help pinpoint the source of the problem.

Leaks in fuel or oil systems are another common concern. These can lead to engine failure or environmental hazards if not addressed quickly. Carefully inspecting seals, gaskets, and hoses for signs of wear or damage can prevent such issues from escalating. Identifying these faults early allows for timely fixes and longer engine life.