When working with large construction vehicles, having a clear understanding of their essential elements is crucial for both operation and maintenance. Each component plays a significant role in ensuring the machinery functions smoothly and efficiently. Whether you’re looking to troubleshoot, repair, or optimize performance, knowing how each section works is fundamental.

These machines are built with complex systems that interact with each other, making them highly effective in tough environments. By familiarizing yourself with their structure and the relationships between various mechanisms, you gain valuable insight into how they perform specific tasks. This knowledge is vital for anyone looking to extend the lifespan of the equipment or reduce downtime.

Understanding Bulldozer Component Functions

Large construction vehicles consist of a variety of mechanisms that work in harmony to carry out heavy-duty tasks. Each mechanism plays a unique role in the overall operation, contributing to the vehicle’s efficiency, power, and durability. Understanding how these systems interact helps operators make informed decisions about maintenance and troubleshooting.

Key Functions of Powertrain and Hydraulic Systems

The powertrain and hydraulic systems are the heart of these machines, driving their movement and enabling precise control over their actions. The powertrain transfers energy from the engine to the tracks, while the hydraulic system powers the lifting and digging components, making these systems essential for effective operation.

Importance of Structural Integrity

Structural components, including the frame and undercarriage, provide the necessary support for the entire machine. These elements ensure stability, allowing the vehicle to withstand the immense pressure generated during operation. Maintaining their integrity is crucial for both safety and performance, as they bear the weight of other systems while navigating tough terrains.

Key Parts of Bulldozer Machinery

Heavy construction vehicles are composed of a wide range of critical components, each contributing to the overall functionality and performance of the machine. These essential systems work together to allow the vehicle to perform a variety of tasks with precision and power, from earthmoving to clearing debris. Understanding the role of each key element is vital for both operators and technicians.

Engine and Powertrain

The engine is the driving force behind the vehicle, generating the power needed for movement and operation. The powertrain transfers this energy from the engine to the tracks, enabling mobility across challenging terrain. A well-maintained powertrain ensures smooth transitions between speeds and enhances overall machine efficiency.

Hydraulic System

The hydraulic system is responsible for controlling vital mechanisms such as the blade and other attachments. By using pressurized fluid, it allows operators to adjust the equipment’s positioning and strength with great precision. Proper functioning of the hydraulic components is essential for effective digging, lifting, and pushing.

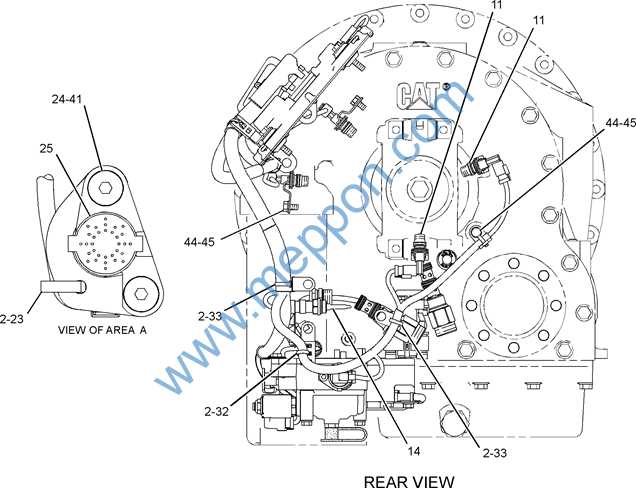

How to Read a Bulldozer Parts Diagram

Interpreting the layout of a heavy machinery system requires understanding how each component is represented and how they interact within the whole. These visual guides provide a detailed overview, illustrating the structure and function of each essential mechanism. Knowing how to read these representations is crucial for performing accurate maintenance and repairs.

Start by identifying the major sections of the vehicle, such as the engine, hydraulic systems, and undercarriage. Each section will be marked with labels that correspond to specific components, often accompanied by a key or legend that explains the symbols and lines. Focus on how each part connects and integrates with others to get a clear understanding of its role.

Understanding the different types of symbols used is key. For example, lines may represent fluid pathways, while arrows indicate movement or flow. This helps in diagnosing issues or replacing parts by providing a visual map of where and how each component fits within the larger structure of the machine.