Maintaining and repairing agricultural machinery is essential to ensuring its long-term efficiency and performance. When it comes to troubleshooting and replacing components, having a clear visual guide is invaluable. This guide helps users identify individual pieces and their functions, enabling a smoother repair process.

By familiarizing yourself with the key components and their locations, you can better assess issues that may arise during operation. Whether you’re dealing with wear and tear or replacing broken pieces, understanding how each part interacts within the system will save time and effort.

Accurate identification of components plays a crucial role in choosing the right replacements. With a detailed reference, you can avoid costly mistakes and ensure compatibility between the parts you use for repairs.

Understanding Bush Hog ATH 720 Components

Each piece of machinery is made up of numerous elements, each serving a distinct function within the system. Familiarizing yourself with these elements is key to ensuring proper operation and identifying potential issues early. In this section, we will delve into the critical components that make up the structure of this equipment, highlighting their roles and interactions.

From the main drive mechanism to the auxiliary parts, each component plays a specific role in maintaining functionality. Understanding how these elements fit together will provide insight into the overall system, enabling you to detect irregularities and perform effective maintenance.

By recognizing the importance of each piece, you can avoid unnecessary repairs and replace only the affected components when needed. This knowledge ultimately enhances the efficiency and lifespan of your equipment, ensuring it performs optimally in the long run.

How to Read the Parts Diagram

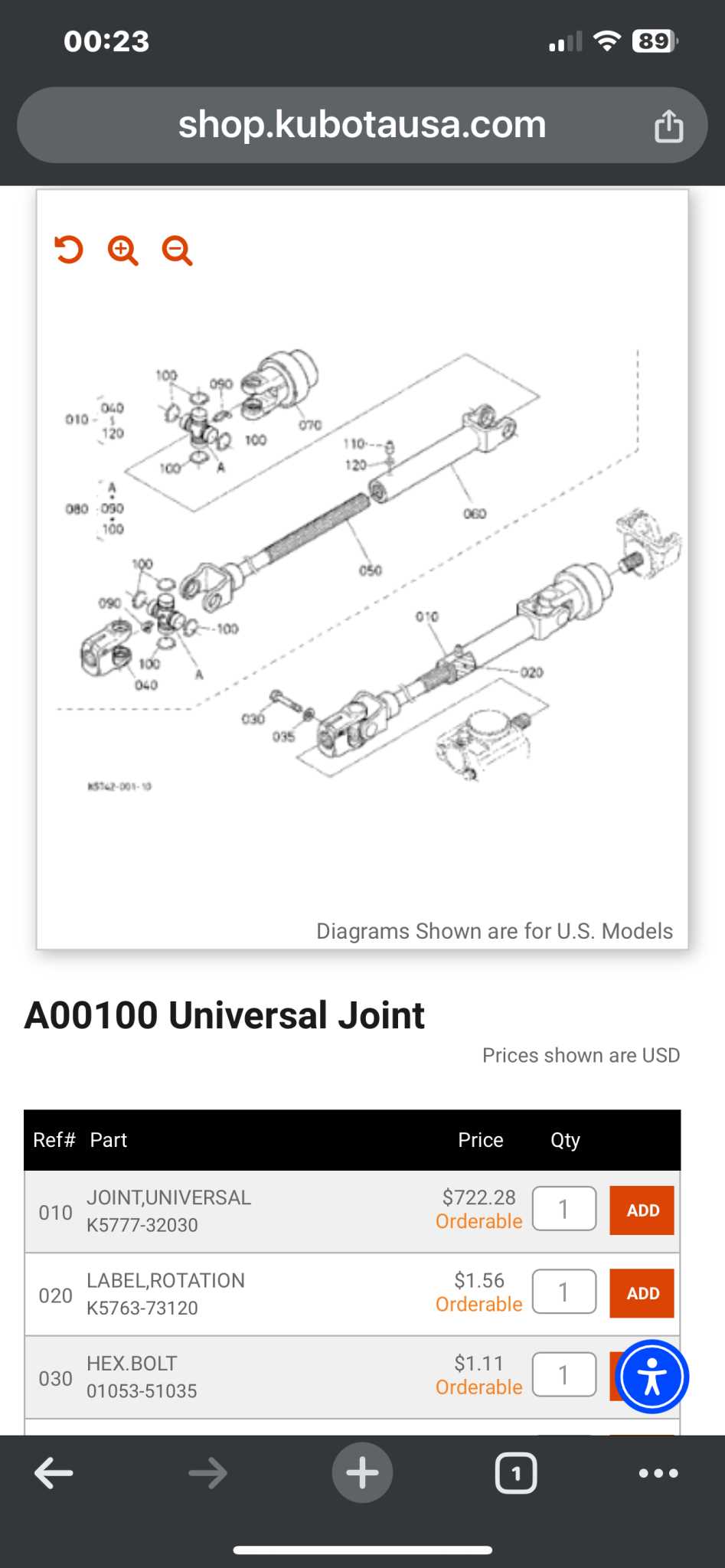

Understanding how to interpret a visual reference for equipment components is essential for effective troubleshooting and repairs. A detailed illustration can provide you with the clarity needed to identify each element of the machinery and its function. By learning to read these references, you can make informed decisions about which parts need attention or replacement.

Key Symbols and Labels

One of the first things to note when studying such references is the use of symbols and labels. These visual cues help you quickly identify the specific parts and their respective locations within the system. Often, the parts will be numbered or marked with a code that corresponds to a detailed list, allowing you to cross-reference and ensure you are selecting the correct item for replacement.

Understanding Component Relationships

Beyond individual parts, it’s important to understand how each piece connects and interacts within the larger system. A visual guide typically shows these relationships, allowing you to see how one part influences the function of others. Recognizing these connections can help you pinpoint underlying issues and choose the right course of action for maintenance or repair.

Common Issues and Replacement Tips

Every piece of machinery is prone to wear and tear over time, and knowing the common issues that arise can help prevent costly breakdowns. Identifying these problems early and understanding how to replace faulty components is crucial for keeping your equipment in optimal working condition. In this section, we’ll explore the most frequent issues that occur and provide helpful tips for replacing the necessary elements.

One common issue is the deterioration of moving parts, such as gears and belts, which experience significant stress during operation. Regular inspection of these elements can help catch problems before they cause a full failure. Replacing worn-out gears or tensioning belts ensures smooth functioning and prevents further damage to the system.

Another frequent concern is the accumulation of dirt, debris, or rust, which can hinder performance and lead to premature wear. Cleaning these areas and replacing any damaged seals or filters will improve the efficiency of your machinery and prolong its lifespan. By staying proactive and addressing these common issues, you can ensure that your equipment continues to operate effectively for years to come.