When dealing with complex machinery, it’s essential to have a clear understanding of its internal structure. Knowing where each component fits and how they interact helps ensure smoother operation and easier troubleshooting. Whether you are maintaining or repairing a system, having a detailed overview of its mechanisms can save time and prevent damage.

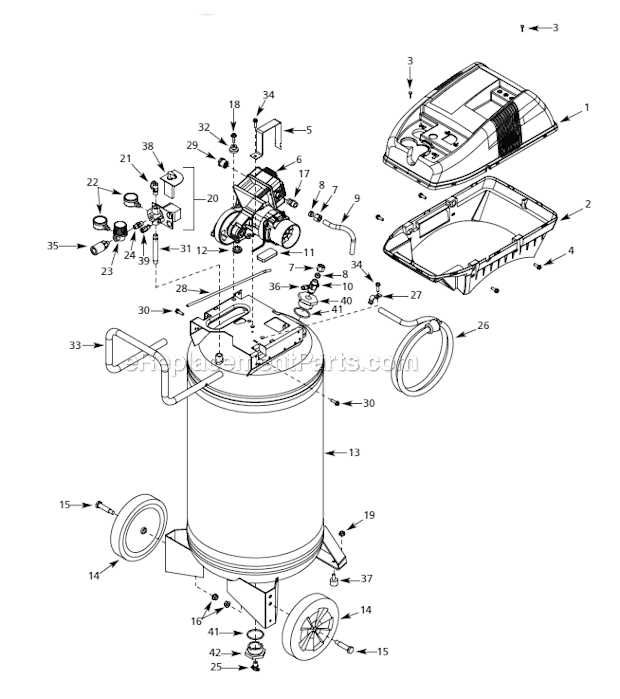

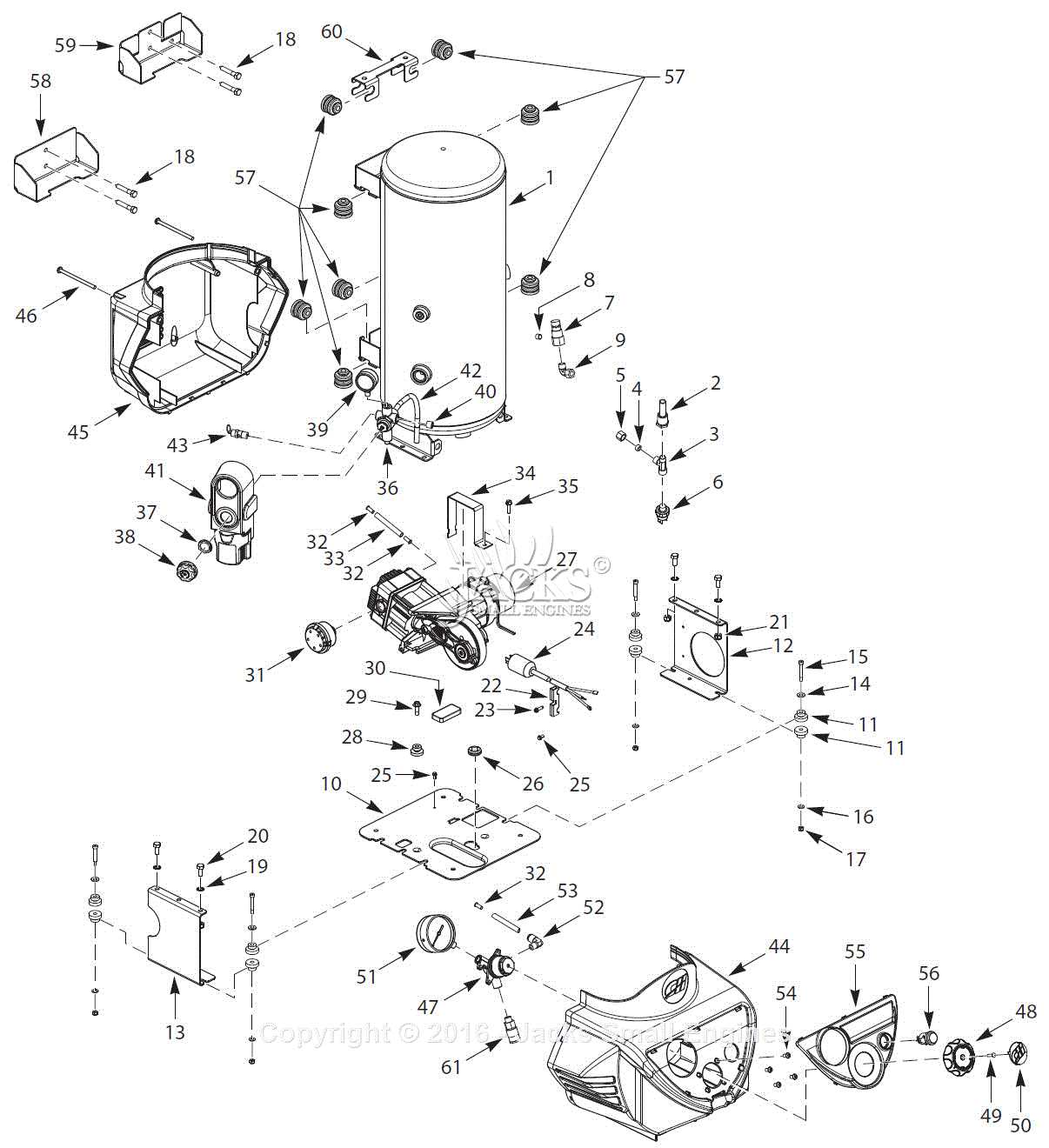

Detailed visual guides are indispensable for those unfamiliar with the internal workings of their equipment. By referring to these schematics, users can accurately identify individual components, understand their function, and perform necessary tasks with confidence. These guides also make it easier to spot wear and tear, helping you avoid major issues in the future.

Efficient repairs and maintenance start with proper knowledge of the system layout. With a step-by-step approach, even beginners can gain the confidence to manage minor fixes and upgrades. Whether it’s for routine checks or unexpected breakdowns, this knowledge will prove to be invaluable over time.

Understanding Your Machine’s Components

To effectively maintain or repair your system, it’s crucial to comprehend the essential elements that make it function. Each individual piece works together to ensure optimal performance. Gaining a clear understanding of these components allows you to diagnose issues faster and ensure everything operates smoothly.

Systems like these are made up of various interconnected elements, each serving a specific role. Familiarity with their functions can greatly reduce repair time and improve overall maintenance routines. Here are the key components you’ll encounter:

- Motor: Provides the necessary power to drive the machine.

- Valves: Control the flow and pressure of air within the system.

- Connectors: Facilitate the connection between different parts, ensuring proper functionality.

- Pumps: Compress and move air throughout the system.

- Filters: Keep the system free of debris and contaminants, ensuring longevity.

Each of these components plays a vital role in the overall functioning of the system. When troubleshooting, understanding how these pieces work together can help pinpoint the source of an issue. Additionally, recognizing signs of wear or damage in any of these parts will make repairs more efficient and effective.

How to Read Machine Schematics

Interpreting technical diagrams is an essential skill for understanding the internal structure of your system. These visual representations allow you to see the relationships between different components and their functions. Learning to read these illustrations can significantly improve your ability to maintain or repair your machine with precision.

Key Elements of a Schematic

A schematic typically includes various symbols and lines that represent the machine’s components and connections. It’s important to familiarize yourself with these symbols, as they provide crucial information about how each part interacts within the system. For instance, symbols for motors, valves, and connectors will look distinct, helping you to quickly identify them when needed.

Step-by-Step Approach

When examining a schematic, start by identifying the main components and their positions within the system. Look for the power source, flow paths, and key control elements. Next, trace the connections between the pieces to understand how they work together. Finally, note any arrows or labels that indicate direction or pressure to ensure you are following the correct flow.

Common Issues and Repair Tips

Even the most reliable systems can experience issues over time. Recognizing common problems early can help you take the necessary steps to prevent further damage. Understanding the root causes of these failures will enable you to apply the right solutions and maintain your equipment in top condition.

Leakages: One of the most frequent issues is air leakage, which can reduce efficiency. Check for cracks or loose connections around seals and gaskets. Tightening or replacing these components often solves the problem.

Overheating: If your system overheats, it may be due to inadequate ventilation or a malfunctioning cooling system. Ensure there is proper airflow and clean any filters that may be obstructing airflow. In some cases, replacing the fan or cooling unit may be necessary.

Reduced Pressure: If the pressure drops unexpectedly, inspect the valves and check for blockages in the flow path. Clean any debris and ensure that all valves are functioning correctly. If the problem persists, it could indicate a faulty valve or pump that requires replacement.

Noise Issues: Excessive noise could be a sign of worn-out bearings or unbalanced components. Lubricate moving parts regularly and check for any parts that may need realignment or replacement to prevent further damage.

By recognizing these issues early and performing simple maintenance steps, you can extend the life of your machine and avoid costly repairs down the line.