When it comes to achieving a smooth and efficient application of coating solutions, knowing the essential components of your equipment is crucial. Understanding the different elements that make up a spraying device ensures effective maintenance and troubleshooting. Every tool is built with specific mechanisms to facilitate a seamless experience, and recognizing each part’s role can significantly improve overall performance.

By familiarizing yourself with the layout and function of these parts, you can better prepare for repairs or upgrades, ensuring the longevity and reliability of your system. Each component, from the power unit to the smaller connectors, plays a vital role in delivering optimal results, making it important to know how to handle them properly.

In this guide, we will break down the various components, how they work together, and how to interpret their arrangement. Understanding these elements empowers users to maintain their equipment efficiently and avoid costly repairs down the line.

Understanding the Key Components of Spraying Systems

To ensure optimal performance and efficiency, it is essential to understand the primary elements that make up a high-functioning spraying system. These systems rely on several integral components working together, each playing a specific role in the overall operation. Knowing how these parts interact can help you troubleshoot issues and improve the longevity of the equipment.

One of the most important aspects is the delivery mechanism, which controls the flow of the material being applied. The power unit, responsible for generating the necessary pressure, is equally crucial for maintaining consistency in performance. Additionally, various connectors and valves contribute to regulating the system’s functionality, ensuring smooth operation throughout the application process.

In this section, we will explore these components in detail, highlighting their function and importance in maintaining high-quality results. Whether you’re performing maintenance or troubleshooting, understanding how each element contributes to the overall process will enable you to keep your system running smoothly.

How to Read the Parts Diagram

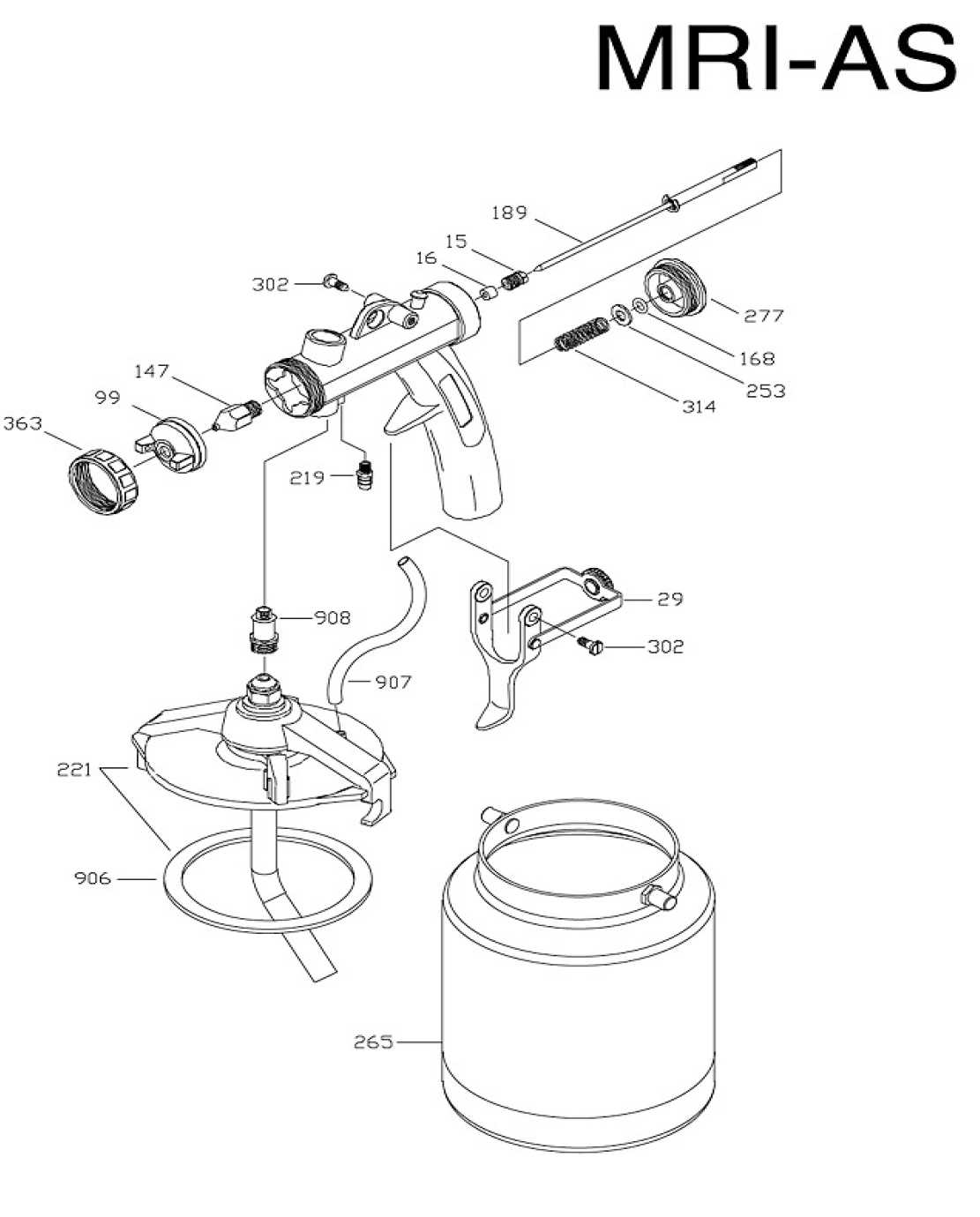

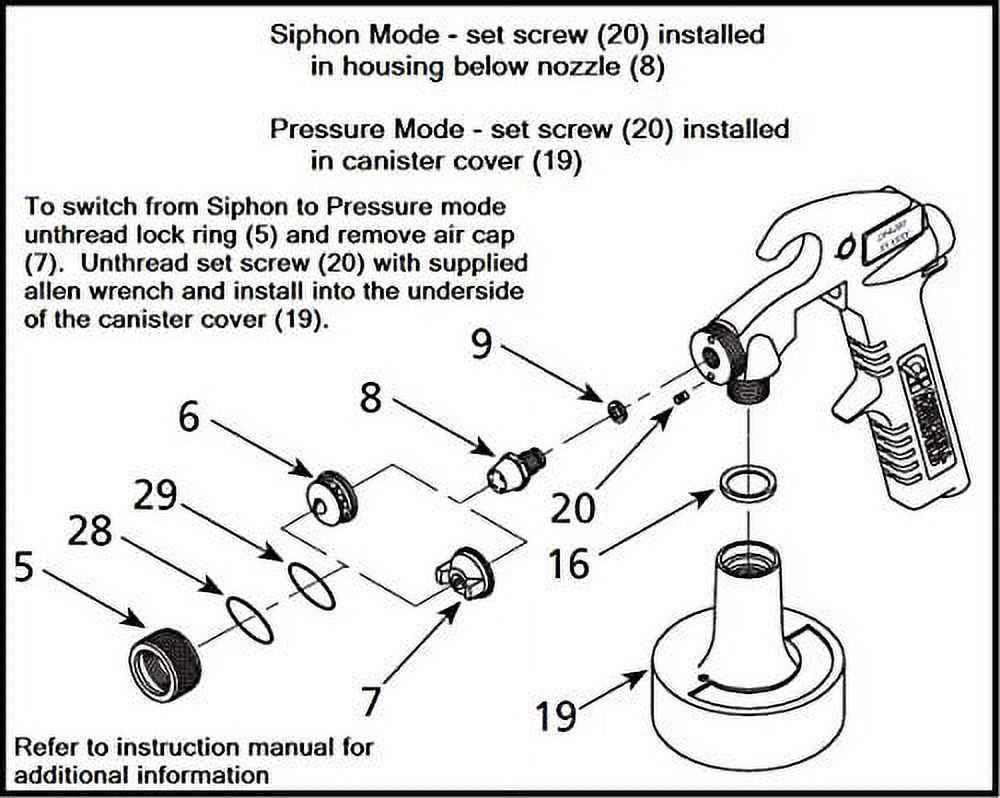

Understanding how to interpret a component map is essential for effective maintenance and repairs. These visual representations serve as guides to show the configuration and relationship between various elements of your system. By carefully analyzing them, you can quickly identify each part’s placement and function, making it easier to address specific issues or carry out upgrades.

Start by recognizing the symbols and labels used to denote different components. Each item will be marked with a reference number, which corresponds to a description or detailed part list. Pay close attention to the connections between the different elements, as these often indicate how they interact with each other to ensure smooth operation. Understanding these links will provide you with the clarity needed to carry out precise repairs or replacements.

Once you familiarize yourself with the layout, you’ll be able to pinpoint areas that require attention. Whether you’re troubleshooting a malfunction or performing routine maintenance, the component map acts as a valuable tool for improving your system’s functionality.

Common Repairs for Spraying Systems

Like any complex equipment, spraying devices may experience issues that require timely attention. Regular wear and tear can lead to malfunctions, but understanding common repairs can help keep the equipment running smoothly. Knowing which components are most likely to fail and how to address them ensures a more efficient repair process, minimizing downtime.

Leaking Connections

One of the most common issues with spraying systems is leaking connections. Over time, seals and gaskets may degrade, leading to leaks that affect performance. Inspect the connectors regularly for signs of wear and replace any damaged seals. Tightening loose fittings can also help prevent fluid leakage, ensuring better control and efficiency during use.

Clogged Filters and Valves

Clogging of filters or valves is another frequent problem, especially when using thicker materials or after prolonged use. Dirt, debris, and residue can build up inside the system, restricting the flow of the fluid. Clean the filters and valves thoroughly, and replace them if necessary, to restore proper flow and prevent over-pressurization.