Every machine is built with a complex system of interconnected elements, each serving a specific function to ensure smooth operation. When it comes to maintenance or repairs, knowing how these components interact is crucial for efficient troubleshooting. Whether you’re a seasoned mechanic or a beginner, understanding the structure and functionality of each part can save valuable time and effort.

Identifying components correctly is the first step in any repair process. A detailed overview of a machine’s internal structure provides clarity on which parts need attention and how to address issues effectively. This knowledge allows for informed decision-making and proper part replacement, ensuring optimal performance.

By following a clear guide to the assembly and functionality of different elements, you can confidently tackle any mechanical issue. Whether it’s fixing minor faults or carrying out major repairs, a structured understanding of the system’s layout will significantly improve your maintenance experience.

Understanding the Machine’s Component Layout

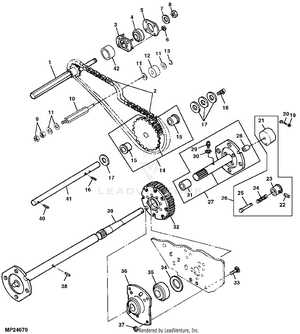

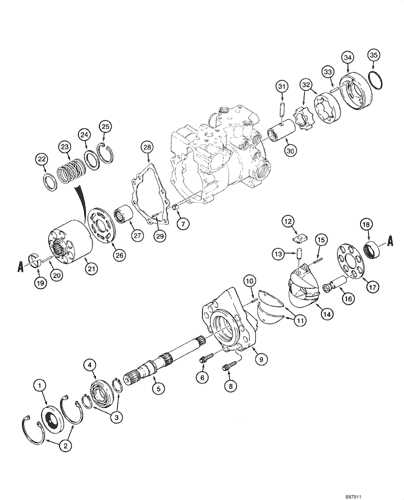

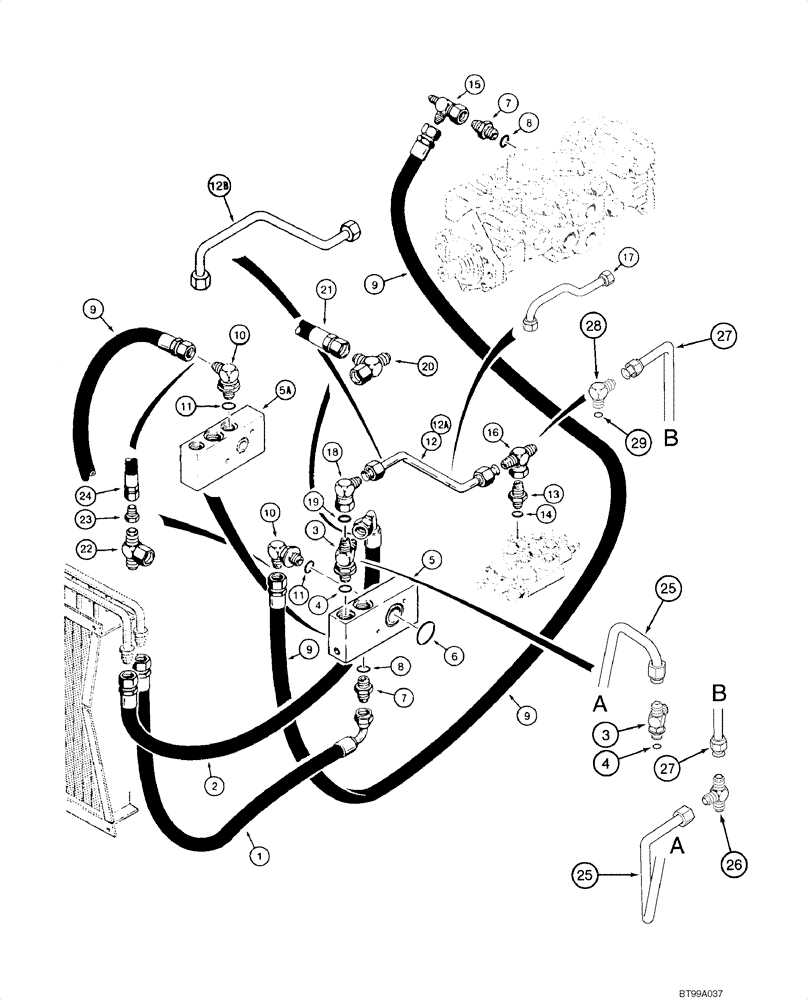

Knowing the internal structure of any machinery is essential for effective maintenance and repairs. A clear visual representation of the assembly allows you to identify each piece, understand its role, and locate potential areas of concern. By familiarizing yourself with how the different sections are interconnected, you can troubleshoot issues more efficiently and perform repairs with greater precision.

Having a comprehensive guide that outlines the arrangement of all major elements simplifies the identification of individual components. This clarity helps in recognizing any worn-out or damaged parts that require attention. Moreover, understanding the entire system’s workflow ensures that every adjustment or replacement is made correctly, preserving the functionality of the entire unit.

Whether you are working on minor repairs or conducting a thorough inspection, a detailed breakdown of the mechanical system provides invaluable insights. This knowledge empowers technicians and operators to make informed decisions, minimizing downtime and extending the machine’s lifespan.

How to Identify Key Components

Recognizing the critical elements of any mechanical system is vital for successful maintenance and repair. Properly identifying each part allows you to assess its condition, understand its function, and determine whether it needs to be replaced or serviced. A systematic approach to examining the machine’s structure ensures that all components are working in harmony and that no critical element is overlooked.

Start with the Basics

Begin by focusing on the primary functional components that are crucial for the system’s operation. These typically include the engine, hydraulic system, and drive mechanisms. Each of these sections contains specific parts responsible for the overall performance, and understanding their role is key to identifying potential issues early on. Use available reference materials to compare each component’s appearance and function, ensuring accuracy in your identification process.

Utilize Reference Guides

Having access to a detailed reference guide can greatly simplify the identification process. Whether it’s a user manual or a technical drawing, these resources will provide you with clear visual cues to match parts to their functions. Look for markings, labels, or distinct features that help differentiate one component from another. With the help of such guides, even complex systems become easier to understand, allowing you to pinpoint exactly which elements require attention.

Step-by-Step Guide for Repairs

Repairing a mechanical system requires a structured approach to ensure that all issues are addressed methodically and accurately. Following a clear step-by-step guide helps you stay organized, reduces the risk of errors, and ensures that the machine is restored to its full functionality. This process involves assessing the issue, gathering the necessary tools, and replacing or fixing faulty components as needed.

Start with an Assessment of the problem. Identify the malfunction by inspecting the machine thoroughly. This could involve checking for obvious signs of damage, wear, or malfunction in key areas such as the engine, transmission, or hydraulic systems. Once the faulty part is located, make a note of its condition and any additional issues that may need attention.

Gather Necessary Tools for the repair. Depending on the nature of the issue, you may need specialized equipment to disassemble the machine and access the affected components. Ensure that you have all the required tools before beginning the repair process to avoid interruptions and unnecessary delays.

Execute the Repair by carefully removing the damaged component and replacing it with a new or refurbished one. Follow manufacturer guidelines for installation, ensuring that all parts are correctly aligned and fastened. After the repair is complete, perform a thorough check to ensure everything is functioning as it should.

Finally, test the system to confirm that the repair was successful. Run the machine through a series of operations to ensure that the issue has been fully resolved and that no further adjustments are necessary.