When working with complex construction equipment, understanding the relationship between its different elements is crucial for efficient operation and maintenance. Identifying each individual component and its function ensures that any issue can be addressed promptly and effectively, keeping the machinery running smoothly.

Having a clear visual representation of the machine’s structure is vital for identifying parts and understanding their interactions. This knowledge not only helps with repairs but also aids in better overall machine management, ensuring longevity and optimal performance.

Maintenance becomes significantly easier when operators are familiar with the layout of the internal mechanisms. Recognizing worn-out or damaged components and replacing them on time can prevent costly downtime and unnecessary repairs.

Understanding the Case 450 Dozer Parts

When managing large machinery, knowing the function and location of each component is essential for smooth operation and troubleshooting. Recognizing how the different elements of a machine work together enhances efficiency and makes identifying problems simpler. This knowledge helps to extend the life of the equipment and reduce repair costs over time.

Key Components and Their Functions

The machinery consists of several key sections that work in unison to perform specific tasks. These sections can range from the engine and transmission system to the hydraulic system and tracks. Understanding how each component functions individually and as part of the larger system is crucial for diagnosing issues or performing preventive maintenance.

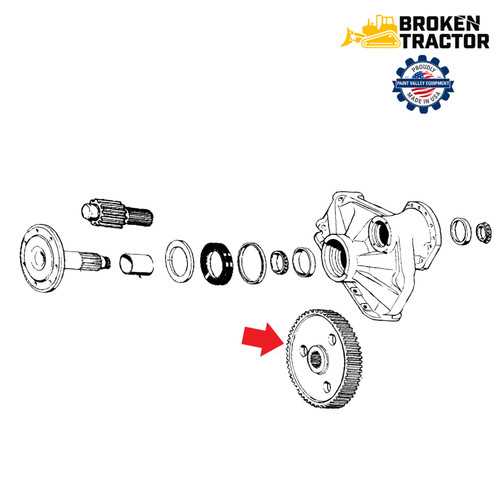

Commonly Replaced Elements

There are parts that typically undergo wear and tear with regular use. These components often require frequent inspection or replacement to maintain the equipment’s performance. Regular maintenance and prompt attention to damaged parts can significantly minimize downtime and repair costs.

| Component | Function | Maintenance Tips |

|---|---|---|

| Engine | Power generation | Regular oil changes and air filter replacement |

| Hydraulic System | Movement and control of heavy parts | Check for leaks and ensure fluid levels are adequate |

| Tracks | Mobility and stability | Inspect for wear and replace damaged links |

Detailed Breakdown of Dozer Components

For efficient operation and optimal performance of heavy machinery, a deep understanding of its individual elements is essential. Each component plays a vital role in the overall functionality, from generating power to controlling movement. Knowing the details of each section allows operators and technicians to identify potential issues early and address them before they lead to major repairs.

The key systems that make up such equipment include the engine, the hydraulic system, the transmission, and the undercarriage. Each of these systems is designed to handle specific tasks, and any malfunction within these components can significantly impact performance. By understanding how each part interacts with others, it becomes easier to troubleshoot problems and ensure the machinery is always ready for use.

Assembly and Maintenance of Dozer Components

The process of assembling and maintaining heavy machinery involves careful attention to detail and the proper understanding of each system. Ensuring that all elements are securely fitted and function as intended is essential for safety and efficiency. Routine maintenance is key to keeping the equipment in peak condition, preventing failures, and extending its lifespan.

Proper Assembly Techniques

Assembly begins with the careful installation of critical components such as the engine, transmission, and hydraulic systems. These parts must be aligned accurately to ensure the proper flow of power and fluid. Each connection point should be inspected for tightness, and all moving parts should be adequately lubricated to prevent friction and wear.

Maintenance for Longevity

Routine checks are crucial to identify any signs of wear or malfunction. Regularly inspecting the engine, fluid levels, and hydraulic systems can prevent costly repairs down the line. It’s also important to monitor the condition of the undercarriage, tracks, and other structural components to ensure safe and reliable operation.

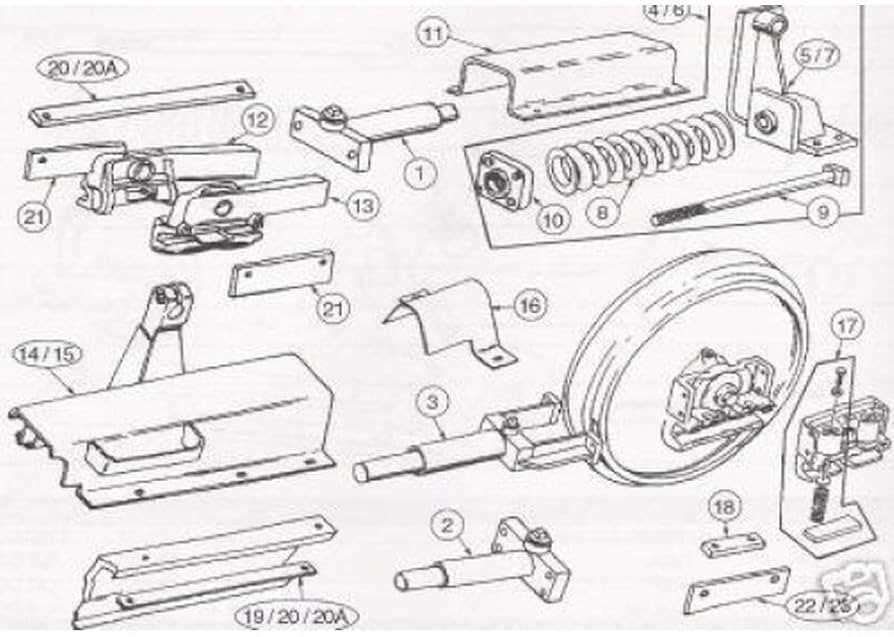

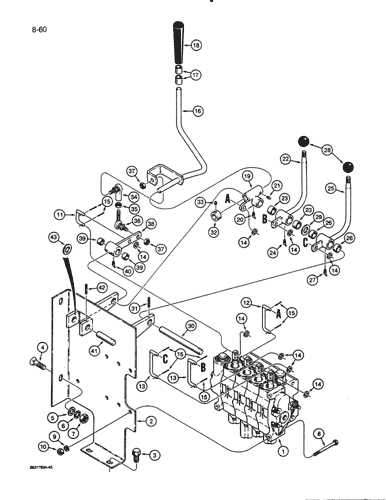

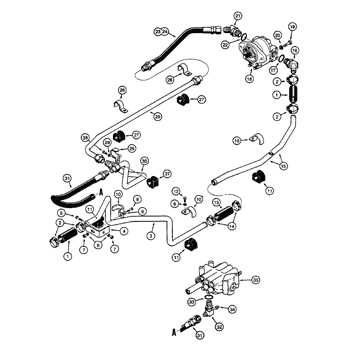

How to Identify Key Parts in a Diagram

Understanding how to read and interpret a machine’s schematic is essential for maintenance and repairs. By carefully studying a visual layout of the machinery, you can quickly pinpoint vital components and understand their relationship to one another. Knowing how to identify these elements enables faster troubleshooting and informed decision-making when performing maintenance tasks.

Steps for Identifying Components

To accurately identify the key parts, follow these simple steps:

- Study the Overview: Begin by reviewing the entire schematic to understand the general layout and flow of systems.

- Focus on Labels: Most diagrams have labels or markings that indicate specific components. Pay attention to these to avoid confusion.

- Refer to the Legend: Many diagrams include a legend or key that provides explanations of symbols and parts, which is crucial for accurate identification.

- Trace the Connections: Follow the lines or arrows that link components together to see how systems interact and work in tandem.

Commonly Highlighted Parts in Schematics

When reviewing a schematic, certain components are typically highlighted or emphasized due to their importance in the machinery’s operation:

- Hydraulic System: Includes pumps, cylinders, and hoses crucial for movement and control.

- Powertrain: The engine and transmission, responsible for power generation and transfer.

- Undercarriage: Tracks, rollers, and sprockets that ensure stability and mobility.

Common Repairs for Heavy Machinery

Heavy equipment is designed to endure tough working conditions, but regular use can lead to wear and tear. Certain components of the machine are more prone to damage and often require attention to maintain optimal functionality. Identifying and addressing common issues promptly can prevent costly downtime and extend the machine’s lifespan.

Frequent repairs typically involve the hydraulic system, powertrain, and undercarriage. These systems are vital for movement, power generation, and stability. Neglecting their maintenance can result in reduced performance or even complete failure, making timely repairs crucial for safe operation.

Hydraulic System Issues often stem from leaks, low fluid levels, or damaged seals. Regular checks can help identify these problems before they escalate. Powertrain Problems usually include issues with the engine, transmission, or belts, and maintaining these elements is essential for ensuring that the equipment runs smoothly. Lastly, Undercarriage Repairs are common, as tracks and rollers can wear out or become misaligned with continued use, affecting the stability and efficiency of the machinery.