Understanding the intricate workings of construction machinery is crucial for efficient maintenance and repair. Knowing how the various components are interconnected allows operators and technicians to troubleshoot and address issues more effectively. With a clear view of how each element functions, users can ensure longevity and performance.

Maintenance and repair tasks become significantly easier when the assembly of a machine is understood in detail. Each part plays a vital role in the overall functionality, and recognizing their position within the system helps in identifying problems quickly. This knowledge is key to reducing downtime and ensuring machines operate at peak efficiency.

Exploring the structure of heavy equipment not only provides insight into its mechanics but also empowers users to make informed decisions regarding upkeep and part replacement. Familiarity with the components can lead to improved performance and reduced repair costs over time.

Understanding the Case 580 Super M Components

Every construction machine is built with an intricate network of elements, each contributing to the overall performance and durability of the equipment. A thorough understanding of these elements is essential for anyone involved in the operation or maintenance of heavy machinery. When operators and technicians are familiar with the structure and function of each piece, they can better manage repairs and identify potential issues before they escalate.

Key Components and Their Functions

The engine, hydraulics, and transmission are the core systems that power any construction vehicle. The engine serves as the powerhouse, generating the energy required for movement and operation. Hydraulics, on the other hand, are responsible for powering various attachments and lifting functions, making them critical to the machine’s versatility. The transmission controls the flow of power to the wheels or tracks, allowing for smooth movement and control over different terrains.

Importance of Regular Maintenance

Regular inspections and upkeep of the main systems help prevent malfunctions and extend the lifespan of the equipment. A proactive approach to maintenance, where each component is checked for wear and tear, ensures that the machine remains in top condition. Neglecting one part, even a small component, can lead to costly repairs down the line, disrupting work schedules and causing unanticipated downtime.

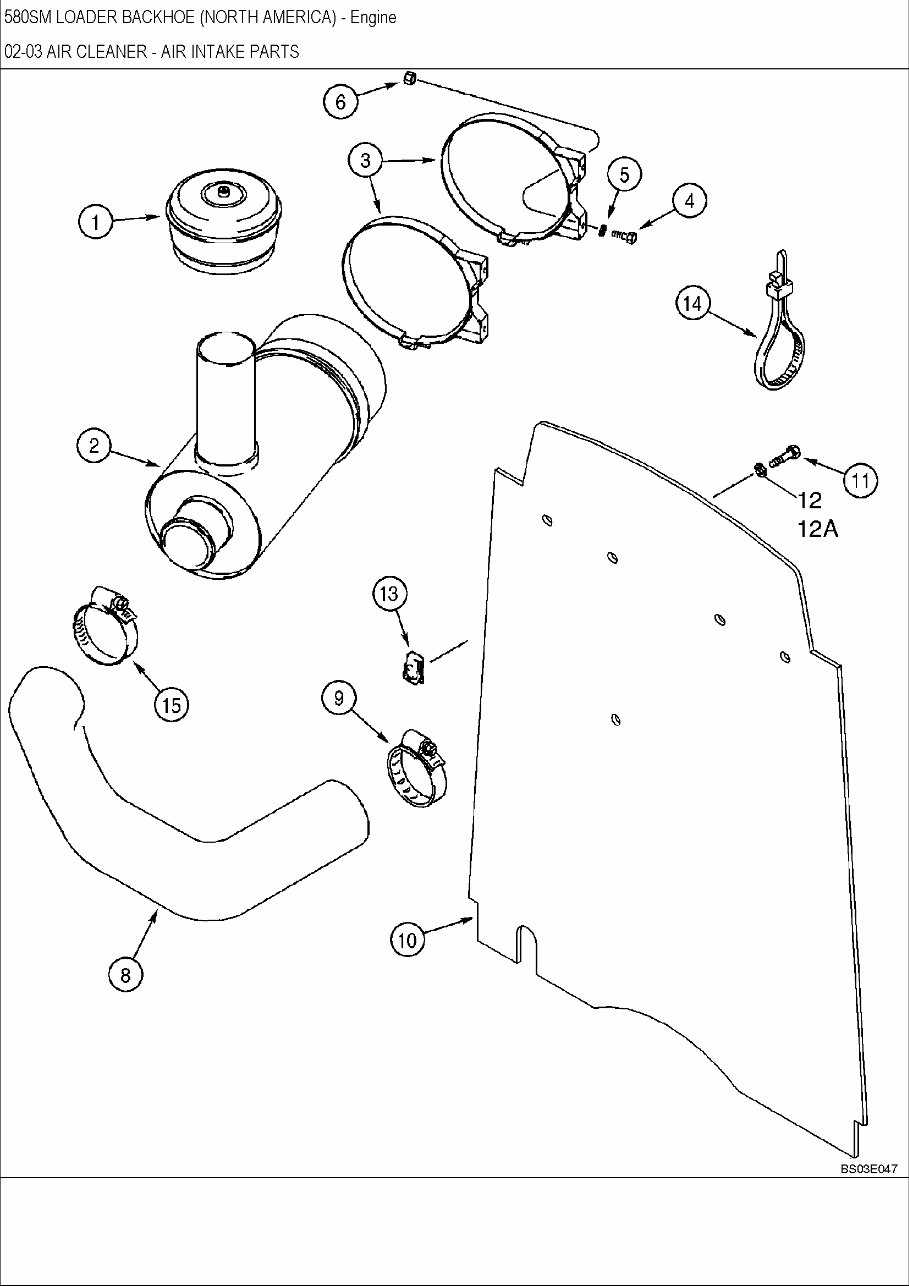

Exploring the Case 580 Super M Engine Parts

The engine is the heart of any heavy-duty vehicle, powering it through demanding tasks and harsh conditions. Understanding the core components that make up the engine is vital for ensuring its optimal performance and longevity. These key parts work in unison to convert fuel into mechanical energy, allowing the machine to operate efficiently and effectively.

At the center of the engine is the cylinder block, which houses the pistons and other moving components. This structure is essential for maintaining the integrity of the engine and managing the forces produced during operation. The crankshaft connects to the pistons, translating their up-and-down motion into rotary motion that drives the machine forward.

Other critical engine components include the valve system, which controls the intake and exhaust of air and fuel, ensuring proper combustion. The timing mechanism coordinates the movement of the valves with the pistons, making sure the engine runs smoothly. Additionally, the cooling system plays a crucial role in regulating engine temperature, preventing overheating and ensuring stable performance under heavy load.

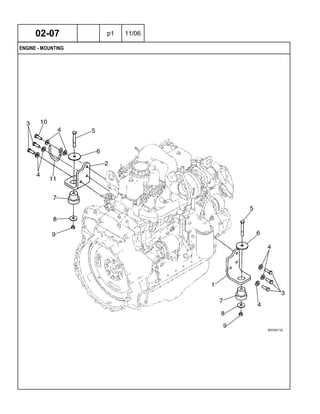

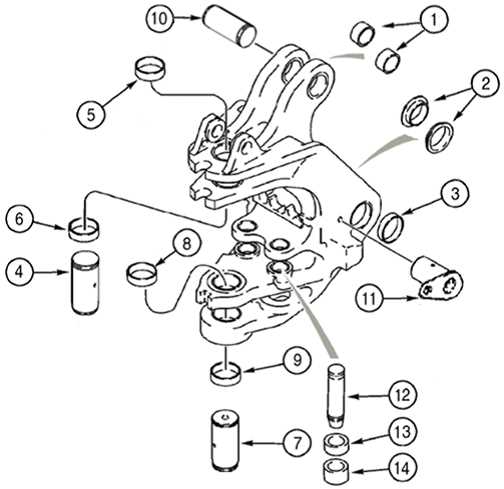

How to Read the Parts Diagram for Case 580 Super M

Interpreting an equipment illustration is an essential skill for anyone involved in machine maintenance and repair. These visual representations provide a clear overview of the different components and how they fit together, making it easier to identify specific parts and their functions. Understanding how to read such diagrams can save time during repairs and help avoid mistakes that may arise from a lack of clarity.

Understanding the Labels and Numbers

Each element in the illustration is typically marked with a unique number or label. These references correspond to the parts catalog, where further details about each component can be found, including specifications, part numbers, and possible replacements. By using the key provided, it’s possible to quickly locate the exact part needed for repairs or replacement.

Identifying the Components and Their Layout

The layout of the diagram is usually organized by system or function, making it easier to understand how each component interacts with others. For example, the engine components may be grouped together, while the hydraulic system may have its own section. By examining the grouping, users can see the relationship between parts and how they contribute to the machine’s overall operation.