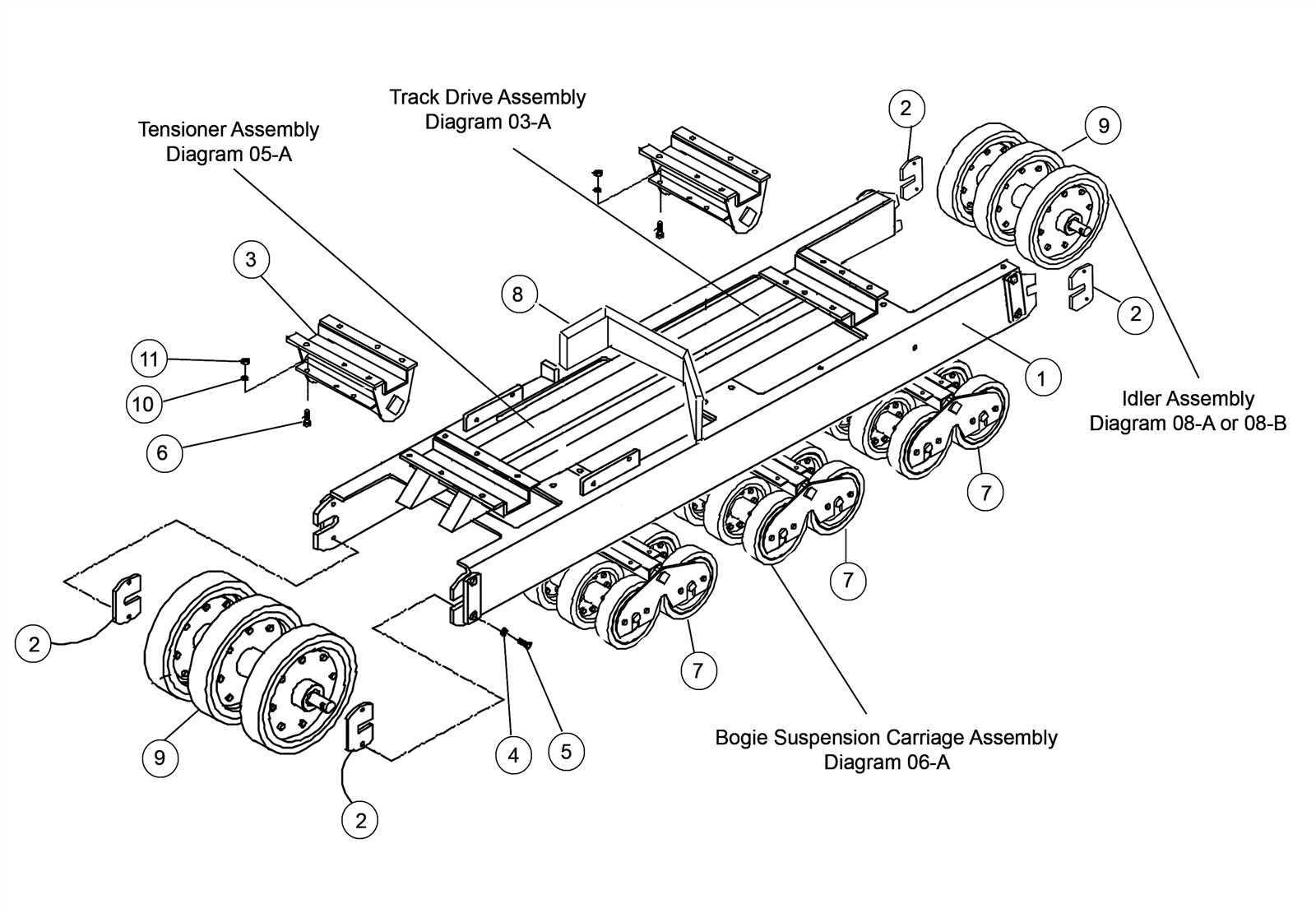

Efficient maintenance of construction equipment relies heavily on understanding its individual components and how they interact. This knowledge helps ensure proper operation, minimizes downtime, and aids in troubleshooting. A clear visual representation can greatly assist in this process, allowing operators to quickly identify and address issues.

Every piece of machinery consists of various interconnected parts, each performing a specific function. Being familiar with their placement and role within the system enhances overall performance and longevity. Recognizing the significance of each component makes maintenance tasks more manageable and helps you make informed decisions when repairs are necessary.

Having access to a detailed schematic can serve as a valuable reference during inspections and routine service. It provides a clear guide, ensuring that every part is in its proper place and functioning as expected. Whether you are a seasoned technician or a new operator, such resources are indispensable for keeping equipment in optimal condition.

Understanding the Equipment’s Layout

When dealing with complex machinery, understanding the arrangement of its key components is essential for ensuring smooth operation. A well-organized system of parts is designed to work together in harmony, and recognizing their placement allows for more efficient maintenance and troubleshooting. This layout provides an organized view of how each component supports the overall functionality of the machine.

Key Functional Elements

The main structure of any machine includes several core units, each serving a specific function. These elements are typically arranged to maximize accessibility and ensure that each piece can be quickly identified and serviced. Knowing where these components are located simplifies the task of monitoring performance and addressing potential issues before they become serious problems.

Impact on Maintenance and Performance

Familiarity with the equipment’s layout directly impacts both routine maintenance and long-term performance. When operators and technicians can easily spot each element and understand its purpose, tasks like lubrication, part replacement, and adjustments become much simpler. A clear understanding of the layout minimizes errors, reduces downtime, and extends the machine’s life.

Key Components of the Machine

Every piece of heavy machinery is made up of several vital units that each contribute to the overall function and efficiency of the equipment. These components are intricately designed to work together, ensuring that the machine operates smoothly and performs its tasks effectively. Understanding the core parts of any machine is essential for operators and technicians alike, as it allows for easier diagnostics, maintenance, and repair.

Among the most crucial elements of this machinery are the engine, hydraulic system, drive train, and lifting mechanism. Each of these components plays a significant role in the machine’s ability to perform complex tasks like lifting, digging, and transporting materials. Regular inspection and upkeep of these key units ensure optimal performance and extend the life of the equipment.

In addition to the primary systems, there are also secondary parts that support the machine’s function, including the cooling and electrical systems. All these elements must be properly maintained and understood in order to prevent malfunctions and reduce downtime. Proper knowledge of each component helps users keep the equipment running smoothly and efficiently.

How to Read the Equipment Schematic

Understanding how to interpret a schematic is a crucial skill when working with complex machinery. These visual representations are designed to give a clear overview of the components and their connections within the system. By learning how to read these diagrams, operators and technicians can easily locate parts, understand their functions, and quickly identify potential issues.

First, it’s important to familiarize yourself with the symbols used in the schematic. Each part is represented by a specific symbol, and understanding these symbols is key to deciphering the layout. Arrows and lines often indicate connections or flow paths, providing insight into how components interact within the system.

Additionally, each schematic usually includes a legend or key, which provides explanations of the symbols and notations used. By referring to this, users can gain a more detailed understanding of the machine’s structure. With practice, reading these diagrams becomes an essential tool for troubleshooting and performing efficient maintenance.