Efficient operation of construction equipment depends on knowing the internal structure and functions of its various components. Each part plays a crucial role in maintaining overall performance and reliability. Understanding these elements helps operators ensure that everything is in top working condition and ready for any task.

Identifying the key elements of the machinery is essential for routine maintenance, repairs, and troubleshooting. The complexity of these machines means that each component must be carefully managed to avoid operational disruptions. By familiarizing yourself with the structure and functions of the key components, you can extend the lifespan and enhance the efficiency of your equipment.

Whether you’re an operator, technician, or enthusiast, knowing how to locate and understand the layout of the machinery can simplify maintenance and reduce downtime. This guide provides a clear overview of the system, helping you navigate through the details efficiently.

Overview of the Equipment Components

To ensure optimal performance and longevity, it is essential to have a clear understanding of the internal workings of heavy machinery. Every system and mechanism in these machines is designed to work together harmoniously, providing power, stability, and precision. A closer look at the layout and functionality of these components reveals their importance in achieving smooth operation and preventing unexpected failures.

Key Systems and Their Roles

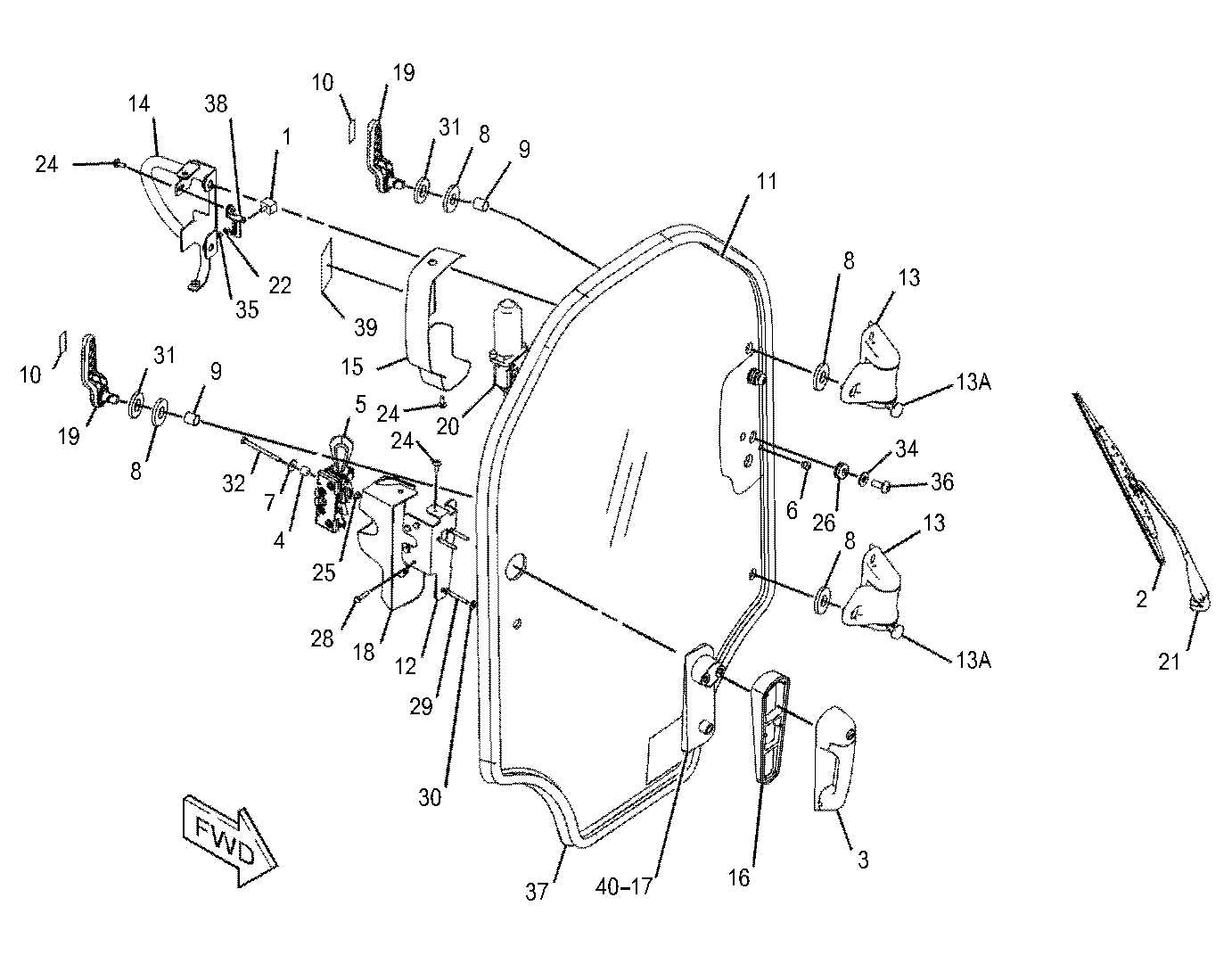

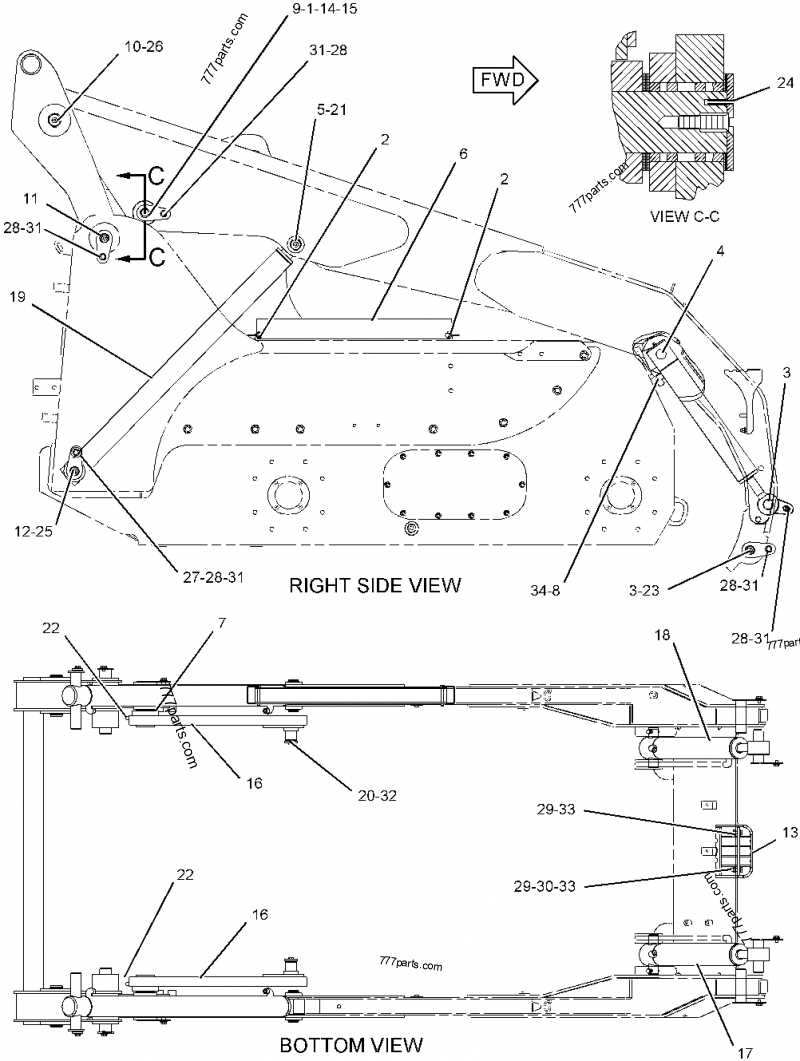

The machinery consists of several interconnected systems, each serving a unique function. From the hydraulic system that powers the machine’s movements to the engine components responsible for generating the necessary force, every part contributes to the overall efficiency. The drive system ensures the machine can maneuver and perform tasks, while the electrical system controls key functions and provides vital feedback to the operator.

Maintaining Component Integrity

Routine maintenance is crucial to keeping the systems running efficiently. Regular inspection of key components, such as the engine, transmission, and hydraulic lines, can help detect potential issues before they cause significant damage. Proper care and attention to these components ensure not only better performance but also a longer service life for the equipment.

Key Parts and Their Functions Explained

Understanding the individual components of machinery is crucial to maximizing performance and minimizing maintenance costs. Each section of the equipment is designed to serve a specific role, and knowing how they function together is essential for smooth operation. A deeper insight into these critical elements allows for better care, quicker troubleshooting, and enhanced longevity.

Hydraulic System is one of the most vital components, responsible for powering many of the machine’s movements. The hydraulic pumps and cylinders enable the lifting, tilting, and other key actions. By controlling the flow of fluid, this system allows the operator to exert precise control over the machine’s performance.

Engine is the heart of the equipment, converting fuel into mechanical power. It drives the vehicle’s movements and powers various systems, ensuring the machine can handle heavy tasks. Proper care of the engine is essential to maintaining overall efficiency and avoiding costly repairs.

Transmission is another essential system, responsible for converting the engine’s power into motion. It regulates the speed and torque, enabling the vehicle to move smoothly under varying conditions. Regular maintenance of the transmission helps ensure a reliable and consistent performance.

Maintaining Your Equipment

Regular maintenance is essential to keep machinery operating efficiently and avoid costly repairs. A proactive approach to care can significantly extend the life of the equipment and ensure it performs at its best, even under challenging conditions. Proper upkeep involves routine inspections, fluid changes, and part replacements as needed.

Checking key systems such as the engine, hydraulic components, and transmission on a regular basis helps identify potential issues early. Ensuring all moving parts are well-lubricated and functioning smoothly is essential for maintaining performance and reducing wear. Additionally, cleaning air filters and ensuring proper cooling system operation are critical tasks that should not be overlooked.

Taking the time to address small maintenance tasks before they escalate into larger problems will help prevent downtime and ensure that your machine is ready for any task at hand.