When it comes to construction machinery, having a clear understanding of its inner workings is essential for proper operation and maintenance. Every machine is made up of intricate systems and individual elements that play a vital role in its overall functionality. Recognizing these components and their interactions can help users identify issues and ensure longevity.

Proper maintenance of these systems relies heavily on recognizing how each part functions and connects. By analyzing the layout and structure, operators can detect wear and tear early on, preventing costly repairs and ensuring optimal performance.

In this guide, we will explore the essential elements of these machines, offering insights into their layout and how understanding these components can improve machine reliability. Whether you’re a professional operator or a machine owner, having this knowledge is invaluable for achieving efficiency and avoiding downtime.

Understanding Heavy Machinery Components

In any large construction machine, the key to its efficiency lies in how its various elements are designed to work together. Each individual component plays a crucial role in the overall operation, from movement to power delivery. Gaining an understanding of these components helps operators troubleshoot, maintain, and optimize machinery performance.

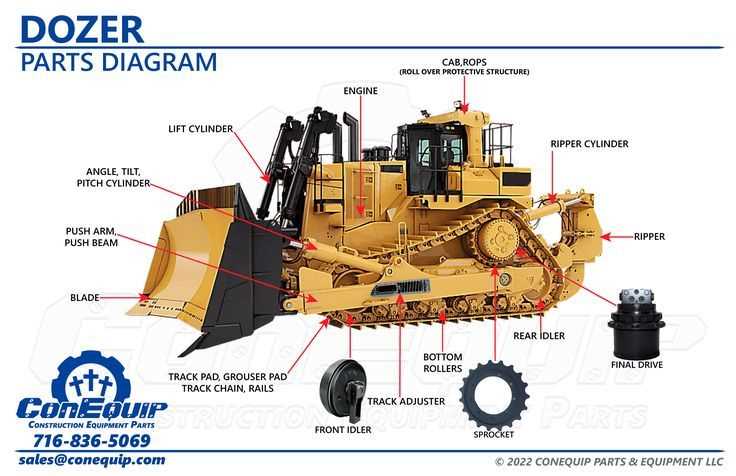

Main Structural Elements

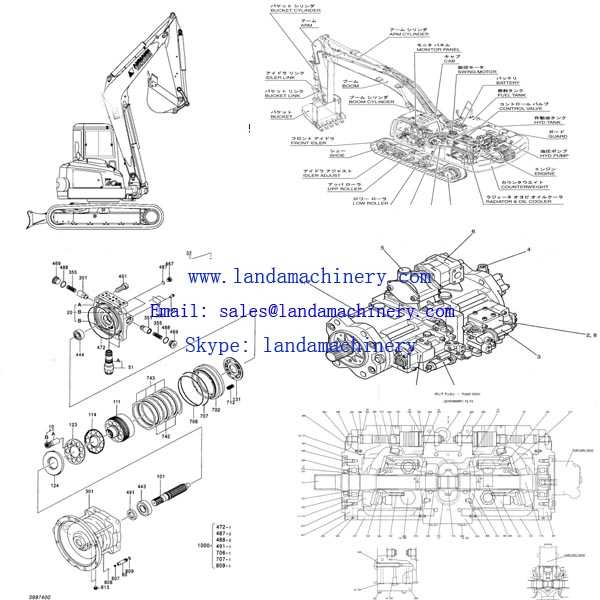

The main structure of the machine includes the frame, undercarriage, and the arm. The frame provides the foundation, ensuring all other components remain secure while withstanding heavy stress. The undercarriage consists of the tracks and rollers, allowing for mobility and stability on various terrains. The arm houses the boom, stick, and bucket, essential for carrying out digging and lifting tasks.

Power and Hydraulic Systems

The hydraulic system is responsible for providing the necessary force for movement. This system includes the hydraulic pump, cylinders, and valves, which work together to transmit power to various parts of the machine. Understanding this system ensures smoother operations and helps detect leaks or failures in the system before they cause significant issues.

Key Components of Heavy Construction Machines

Every large construction vehicle is designed with multiple critical elements, each serving a specific function that contributes to the machine’s overall efficiency. Understanding these fundamental components allows for better maintenance practices, quicker identification of issues, and a deeper understanding of the machine’s capabilities. Each system and mechanism must work in harmony for smooth operation on construction sites.

Powertrain systems are at the heart of any machine, providing the energy needed to drive the vehicle and its attachments. These include the engine, transmission, and final drive, which together convert fuel into the necessary force for movement. Without a properly functioning powertrain, the vehicle will struggle to perform its tasks effectively.

The hydraulic system is another crucial component, allowing for precise control of movement and force. Through hydraulic cylinders, pumps, and motors, the system drives the arm, bucket, and other parts, enabling tasks such as lifting and digging. The efficiency of the hydraulic system is key to maintaining productivity and reducing downtime on-site.

How to Read Construction Machinery Layouts

Understanding the layout of heavy machinery is essential for maintenance and repair tasks. These visual representations provide clear information about the various components, their placement, and how they interact within the machine. Learning how to interpret these drawings helps operators and technicians troubleshoot issues, plan repairs, and ensure that the vehicle operates at peak efficiency.

Identifying Key Symbols and Labels

In any schematic, various symbols and labels are used to represent different components and systems. These might include hydraulic lines, electrical connections, and mechanical parts. Each symbol follows a standardized system, allowing professionals to quickly identify the function of each part without needing to look up descriptions. Understanding these symbols is crucial for navigating complex layouts effectively.

Understanding Component Relationships

These layouts often show how components are connected and interact with each other. For instance, lines may indicate fluid or electrical flow, while arrows can represent movement or force. By understanding these relationships, you can better grasp how the machine operates as a whole, making it easier to spot malfunctions or areas that may require attention during routine checks.

Interpreting Machinery Components for Maintenance

For efficient upkeep of construction vehicles, it is essential to have a clear understanding of how various systems and elements function together. Interpreting the layout and understanding the roles of individual components allows for more accurate maintenance procedures, helping technicians pinpoint issues before they develop into costly problems. Recognizing these elements during routine inspections ensures machines remain in optimal condition for longer periods.

Each system, from the engine to the hydraulic components, has specific maintenance requirements. By understanding the layout, professionals can easily locate areas prone to wear and tear, check for fluid leaks, and monitor pressure levels. Regular checks on key components help in early identification of potential failures, saving time and reducing the risk of major repairs.

In addition, comprehending the relationship between the components allows for troubleshooting. If an issue arises, knowing which systems depend on each other helps technicians narrow down the source of the problem quickly. This approach not only speeds up repairs but also prevents unnecessary disassembly of the machine, ensuring minimal downtime.

Common Issues with Heavy Machinery Components

Heavy construction machines, like any complex system, are susceptible to a range of issues that can affect their efficiency and reliability. Identifying common problems early can save significant time and cost by preventing major breakdowns. Understanding where these issues tend to arise and how to address them is key to keeping the equipment in top working condition.

Hydraulic System Failures

The hydraulic system is one of the most critical components of any construction machine, and it is prone to certain problems over time. Common issues include:

- Leaks in hoses or fittings

- Low fluid levels or contamination

- Malfunctioning pumps or valves

- Overheating of the hydraulic fluid

Regular checks of the hydraulic fluid and seals can help prevent these issues from escalating, ensuring that the system operates smoothly and effectively.

Wear and Tear on Mechanical Components

Mechanical parts such as the tracks, gears, and buckets often suffer from wear and tear due to constant use. Some typical issues include:

- Cracks or breaks in the frame or undercarriage

- Worn teeth on the digging bucket

- Damaged rollers and tracks

Frequent inspection of these elements and timely replacement or repair of damaged components is crucial to avoiding costly downtime or extensive repairs.