Maintaining heavy machinery is essential for optimal performance and longevity. Understanding the individual elements that make up the machine is key to troubleshooting and ensuring its smooth operation. A clear understanding of each component allows operators to identify wear, plan for repairs, and manage routine maintenance effectively.

In this guide, we will explore the key sections of a typical construction vehicle’s layout. By examining how each part interacts, operators can gain valuable insight into the machinery’s overall functioning. Proper knowledge of these areas helps reduce downtime and improves safety, ultimately enhancing worksite efficiency.

Being familiar with the main components and their respective functions allows workers to make informed decisions when dealing with mechanical issues. Regular checks and understanding how each element contributes to the machine’s success can lead to cost-effective repairs and extend the life of the equipment.

Understanding Heavy Machinery Components

To properly operate and maintain construction equipment, it’s essential to have a comprehensive understanding of the vehicle’s individual elements. Each component plays a critical role in the overall functionality and performance of the machine. Knowing how these parts work together ensures smoother operations and helps with troubleshooting when issues arise.

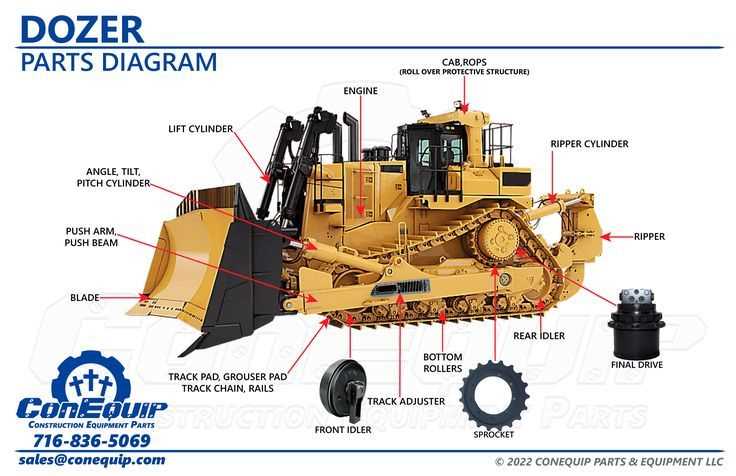

The primary systems of such machinery include the engine, hydraulic system, transmission, and undercarriage. Each section has a specific task, whether it’s powering the vehicle, controlling movement, or supporting the structure. Understanding their interactions is key to making informed decisions about maintenance and repair.

For example, the hydraulic system is responsible for the vehicle’s lifting and maneuvering abilities. Regular inspection and understanding of its components, such as pumps, cylinders, and hoses, are crucial for preventing breakdowns. Similarly, the undercarriage is essential for stability and movement, as it absorbs the machine’s weight and provides traction on various surfaces.

Having a solid grasp of these essential systems not only prevents costly repairs but also optimizes the vehicle’s lifespan. Regular maintenance, such as checking fluid levels, inspecting critical parts, and replacing worn components, ensures that the machine remains reliable and efficient.

How to Read a Machine Layout Illustration

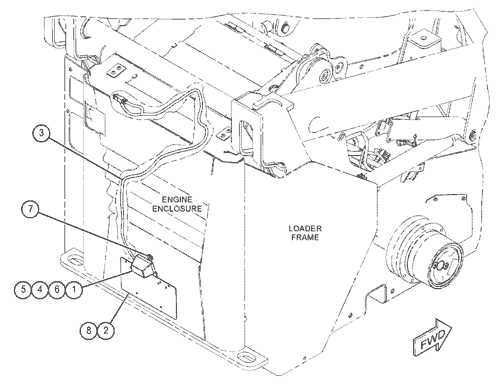

Interpreting a layout illustration of heavy machinery can initially seem daunting, but understanding the visual representation of components is essential for effective maintenance and repair. These illustrations are designed to clearly display the machine’s structure, allowing operators to identify and troubleshoot issues quickly.

Each component is represented symbolically, typically using standardized icons or line drawings that show the position and relationship of the parts. By familiarizing yourself with these symbols and their placement, you can better understand the machine’s overall functioning. Knowing where each element is located helps in addressing specific issues without needing to physically dismantle the equipment.

To read these illustrations effectively, start by identifying the major systems–such as the engine, transmission, or hydraulic system. Focus on the key components within these systems, such as pumps, filters, or cylinders. Each part is typically labeled with reference numbers that correspond to detailed descriptions or part lists found in the accompanying documentation.

Familiarity with the layout allows you to quickly locate the components that need attention and follow the appropriate troubleshooting steps. A good understanding of these visual guides significantly improves repair efficiency and reduces errors during maintenance tasks.

Key Parts for Machine Maintenance

Proper upkeep of construction machinery relies heavily on regular inspection and care of its vital components. By focusing on the most critical elements, operators can ensure the machine runs smoothly, preventing costly breakdowns and extending its service life.

Hydraulic System

The hydraulic system is one of the most important areas to monitor. This system controls lifting, tilting, and movement, making it crucial for the overall performance of the equipment. Regular inspection of hydraulic fluid levels, hoses, cylinders, and pumps is essential to prevent leaks and ensure proper function. Neglecting this system can lead to costly repairs and machine downtime.

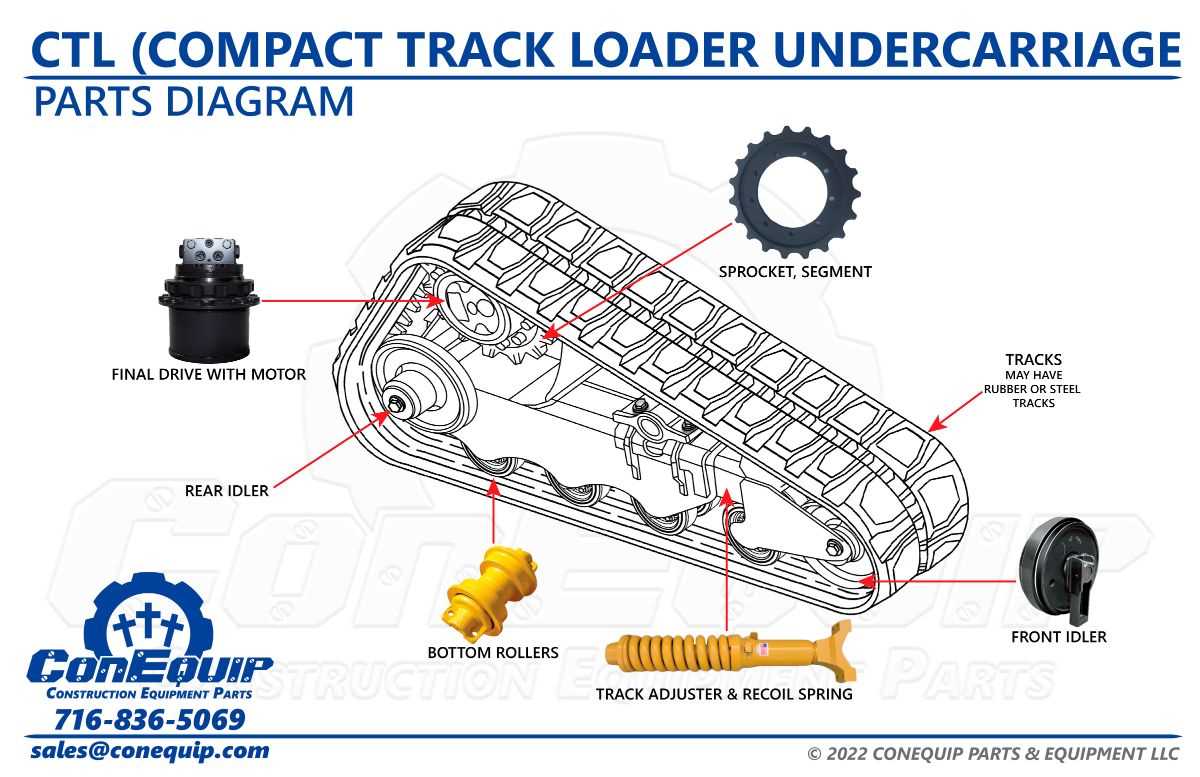

Undercarriage and Tracks

The undercarriage plays a pivotal role in the machine’s stability and mobility. It supports the entire structure and is responsible for the machine’s traction. Regular inspection of the tracks, rollers, and sprockets helps detect signs of wear and tear. Keeping the undercarriage in top condition allows for better maneuverability and reduces the risk of failure on the job site.